Ultrahigh-mechanical-strength ultrathin film for flow battery as well as preparation and application of ultrathin film

A liquid flow battery and liquid phase technology, applied in fuel cells, regenerative fuel cells, circuits, etc., can solve the problems of low conductivity and poor selectivity of all-vanadium redox flow battery membranes, and achieve high energy efficiency, morphology and performance Controllable adjustment, obvious performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The ion-conducting membrane is prepared by the following process:

[0039] (1) Dissolve PBI in DMAc, stir well at 20°C for 24 hours to make a uniform blend solution, and then stand at room temperature for 24 hours to remove air bubbles in the blend solution; the PBI concentration is 15wt%.

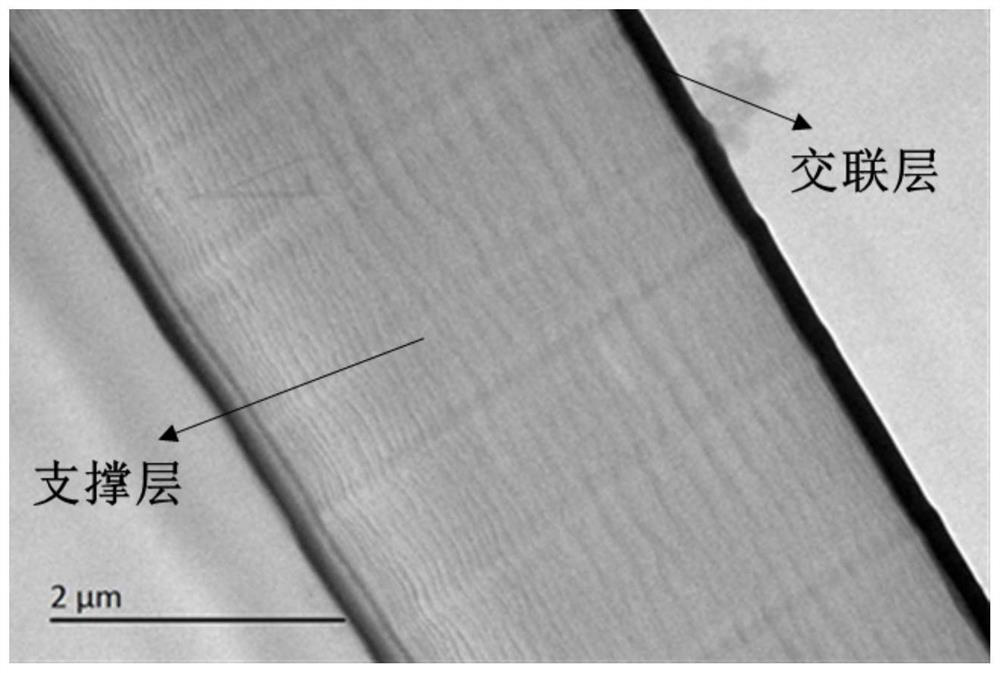

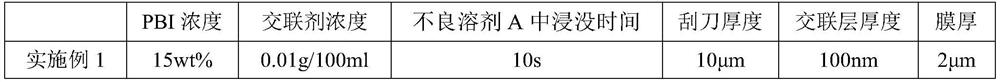

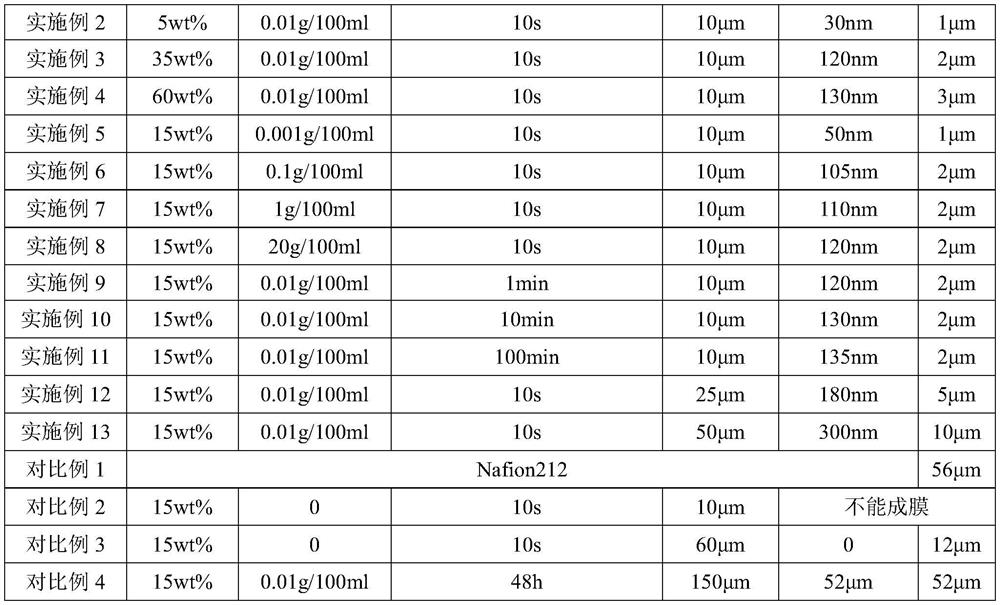

[0040] (2) Pour the blended solution prepared in step (1) on one side of the flat plate, volatilize the solvent for 10 s, use a 10 μm spatula to scrape on the flat plate, and then immerse it at 20°C until it contains 1,3,5-benzenetrimethyl. In the n-heptane solution of acid chloride for 10s, every 100 mL of n-heptane contains 0.01 g of 1,3,5-benzenetricarbonyl chloride; then transferred to water to cure to form a film. The formed film is an ultra-thin and dense film with a double-layer structure of a cross-linked layer and a support layer, the thickness of the cross-linked layer is 100 nm, and the film thickness is 2 μm.

Embodiment 2-13

[0042] Change the parameters in Table 1 below, and other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com