Automatic control system for waste acid treatment

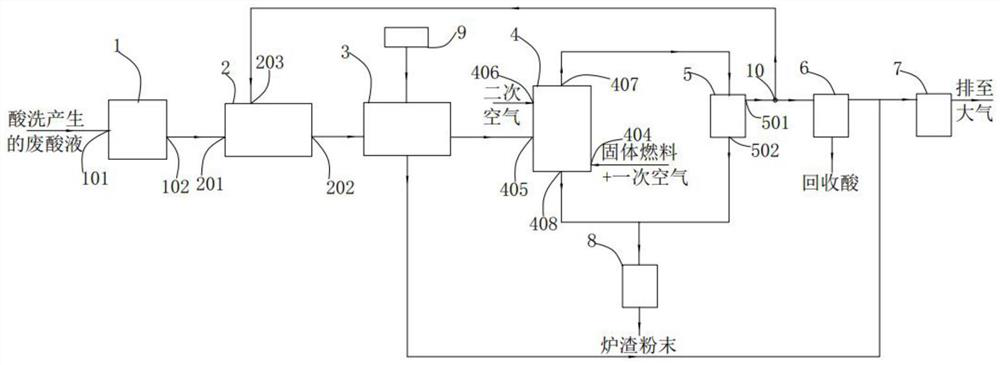

An automatic control system, waste acid technology, applied in the direction of coating, chemical instruments and methods, process efficiency improvement, etc., can solve the problem of easy blockage and damage of nozzles and pre-concentrators, poor continuous stability of production, high fuel consumption, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0155] S1, open the first feed port 404 to input solid fuel and primary air into the roaster 4, open the third feed port 406 to input secondary air into the roaster 4 simultaneously, wherein the calorific value of the solid fuel is 10MJ / Kg, The input speed is 3Kg / min, the peroxidation coefficient in the melting chamber 401 is 0.8, and the peroxidation coefficient in the combustion chamber 403 is 1.2;

[0156] S2, the solid fuel is melted and liquefied in the roasting furnace 4 to generate liquid slag and combustible flue gas, the pressure in the furnace is -0.01MPa, and the combustible flue gas moves upward under the action of primary air and negative pressure in the furnace, and the moving speed is about is 0.4m / s, and then burns in the combustion chamber 403, the furnace gas generated by the combustion is discharged through the furnace gas discharge port 407 in the upper part of the roasting furnace 4, and the solid particles generated by the combustion fall into the liquid s...

Embodiment 2

[0164] S1, open the first feed port 404 to input solid fuel and primary air into the roaster 4, open the third feed port 406 to input secondary air into the roaster 4 simultaneously, wherein the calorific value of the solid fuel is 14MJ / Kg, The input speed is 3Kg / min, the peroxidation coefficient in the melting chamber 401 is 0.9, and the peroxidation coefficient in the combustion chamber 403 is 1.1;

[0165] S2, the solid fuel is melted and liquefied in the roasting furnace 4 to generate liquid slag and combustible flue gas, the pressure in the furnace is -0.03MPa, and the combustible flue gas moves upward under the action of primary air and negative pressure in the furnace, and the moving speed is about is 0.5m / s, and then burns in the combustion chamber 403, the furnace gas generated by the combustion is discharged through the furnace gas discharge port 407 in the upper part of the roasting furnace 4, and the solid particles generated by the combustion fall into the liquid s...

Embodiment 3

[0173] The slag powder processed by the crushing device 8 in the above-mentioned embodiments 1 and 2 was used as a rust inhibitor to prepare an anti-corrosion coating. The anti-corrosion coating includes: 65 parts by weight of acrylic emulsion, 20 parts by weight of pure water, 12 parts by weight of epoxy resin parts by weight, 10 parts by weight of wollastonite, 3 parts by weight of phosphoric acid, 1 part by weight of a rust inhibitor, and 0.5 part by weight of a dispersant.

[0174] The preparation process of the anti-corrosion coating is as follows: pure water, wollastonite, phosphoric acid, rust inhibitor and dispersant are added to a grinding machine, and after grinding to an average particle size of 50-60 um, acrylic emulsion and epoxy resin are added, and the mixture is stirred. After uniformity, the pH was adjusted to 9 to obtain an anti-corrosion coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com