Preparation method of casein micelle concentrated solution with high thermal stability and low viscosity

A technology of high thermal stability and casein glue, which is applied in the field of preparation of high thermal stability and low viscosity casein micelle concentrate, can solve the problems of precipitation, casein micelle aggregation, gelation, etc., and achieve low relative viscosity, Ease of drinking, high heat stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

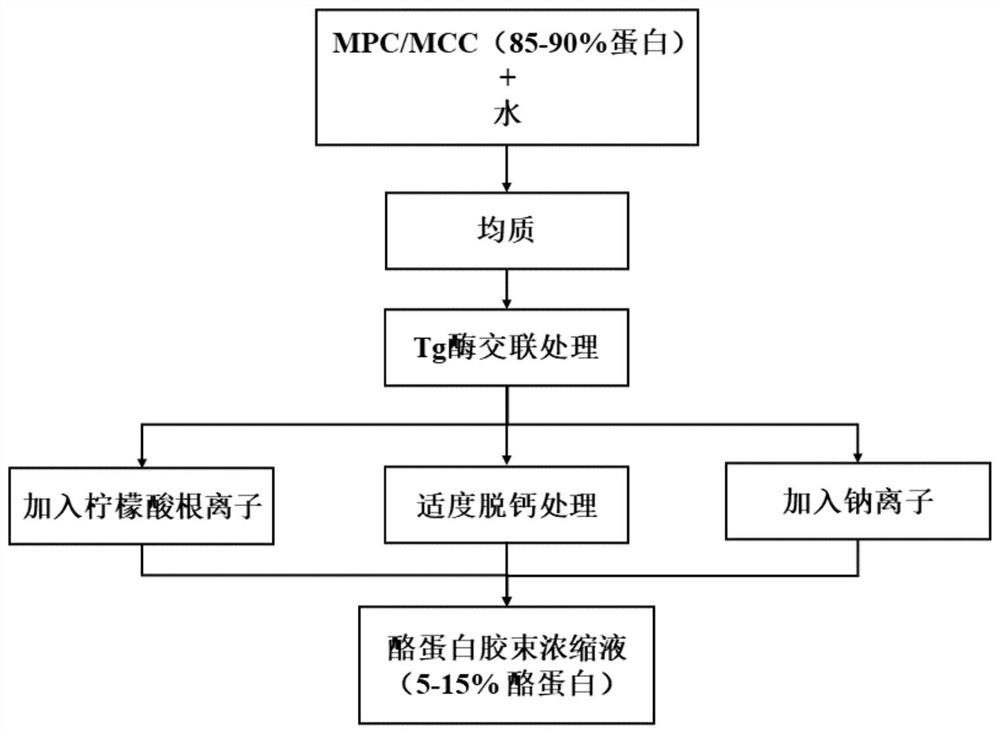

Method used

Image

Examples

Embodiment 1

[0079]

Embodiment 2

[0086]

Embodiment 3

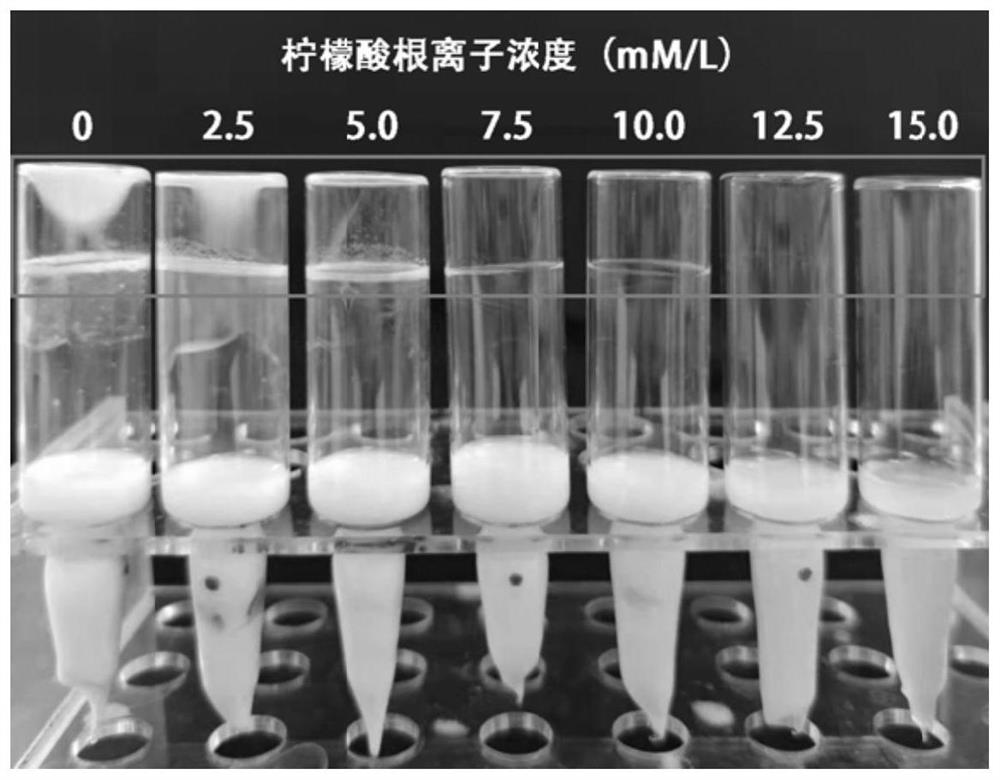

When the proportion of sodium is too high, the pH of the concentrate increases to alkaline, and the negative charge of casein increases, which promotes the dissolution of casein micelles.

When the proportion of citric acid is too high, the pH of the concentrated solution decreases to a slightly acidic, and the casein

The negative charge is reduced, which promotes binding between the caseins, resulting in an increase in the viscosity of the concentrate. Therefore, in the preparation of case eggs by MCC

In the case of white micelle concentrate, the molar ratio of trisodium citrate and citric acid may preferably be 7.5:2.5-8.5:1.5, so that the pH of the concentrate is

Maintain neutrality and make concentrates with high thermal stability and low viscosity.

The physicochemical properties of casein micelle concentrate in the embodiment 3 of table 3

[0094]

[0095] Note: different lowercase letters in the same column represent significant differences between the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com