Monolithic iron-molybdenum catalyst for preparing formaldehyde through methanol oxidation as well as preparation and application of monolithic iron-molybdenum catalyst

A catalyst and monolithic technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, carbon-based compound preparation, etc., can solve the complicated tablet forming process, time-consuming filling process, and Process complexity and other issues, to achieve the effect of simplifying the filling process, improving service life and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] First, dissolve 55 grams of ammonium heptamolybdate in 500 milliliters of deionized water, add concentrated nitric acid (68% by mass, the same below), adjust the pH of the above dissolution to 1.7, and then heat to 60 ° C; then add 52.5 grams of Ferric nitrate was dissolved in 200 ml of deionized water, also heated to 60 ° C, under the condition of vigorous stirring (800 rpm / min), the above ferric nitrate solution was added dropwise to the acidified ammonium molybdate solution. Aging for 12 hours.

[0022] According to the size of the tubular reactor for methanol oxidation in industry (the inner diameter of the tubular reactor for methanol oxidation in industry is 20 mm and the height is 1000 mm), a metal copper corrugated mesh with an open cross-flow structure with an outer diameter of 19 mm and a length of 1000 mm is selected as the whole First, spray a layer of urea-formaldehyde resin adhesive on the surface of the carrier, the thickness is controlled at 0.01mm, and ...

Embodiment 2

[0025] Example 2: Different Support Types (Metallic Copper Open Cell Foam)

[0026] First, dissolve 55 g of ammonium heptamolybdate in 500 ml of deionized water, then add concentrated nitric acid (68% by mass), adjust the pH of the above dissolution to 1.7, and then heat to 60°C; then dissolve 52.5 g of ferric nitrate To 200 ml of deionized water, also heated to 60 ° C, under the condition of vigorous stirring (800 rpm / min), the above ferric nitrate solution was added dropwise to the acidified ammonium molybdate solution, and then aged at 90 ° C for 12 Hour.

[0027] According to the size of the tubular reactor for methanol oxidation in industry (the inner diameter of the tubular reactor for methanol oxidation in industry is 20 mm and the height is 1000 mm), a metal copper open cell foam with an outer diameter of 19 mm and a length of 1000 mm is selected as the integral carrier. In the electrostatic spraying method, firstly, spray a layer of urea-formaldehyde resin adhesive o...

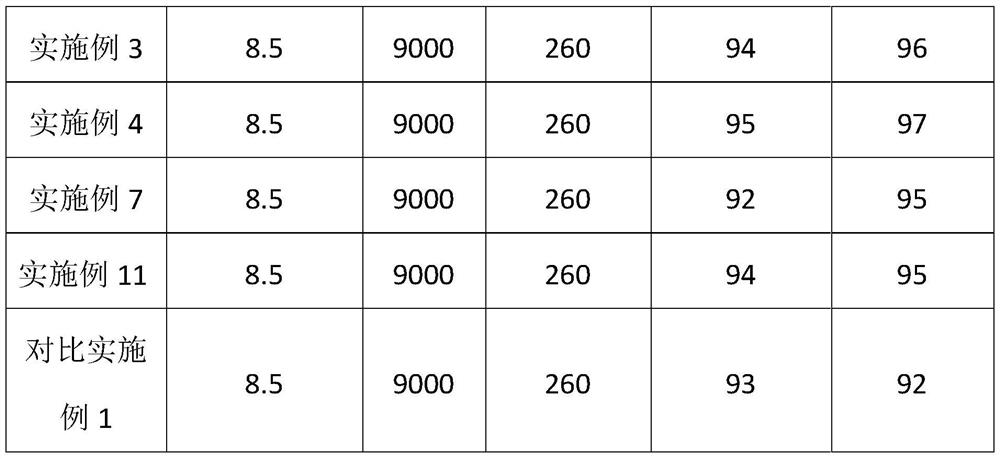

Embodiment 3

[0028] Example 3: Different carrier types (honeycomb copper-aluminum alloy monazite)

[0029] First, dissolve 55 g of ammonium heptamolybdate in 500 ml of deionized water, then add concentrated nitric acid (68% by mass), adjust the pH of the above dissolution to 1.7, and then heat to 60°C; then dissolve 52.5 g of ferric nitrate To 200 ml of deionized water, also heated to 60 ° C, under the condition of vigorous stirring (800 rpm / min), the above ferric nitrate solution was added dropwise to the acidified ammonium molybdate solution, and then aged at 90 ° C for 12 Hour.

[0030] According to the size of the tubular reactor for methanol oxidation in industry (the inner diameter of the tubular reactor for methanol oxidation in industry is 20mm and the height is 1000mm), honeycomb copper-aluminum alloy monazite with an outer diameter of 19mm and a length of 1000mm is selected as the integral carrier , Using electrostatic spraying, firstly spray a layer of urea-formaldehyde resin a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com