Anti-cracking and heat-insulating regenerated rubber mortar and preparation method thereof

A technology of recycled rubber and mortar, which is applied in the field of building materials to achieve the effects of tight combination, enhanced crack resistance, and strong interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

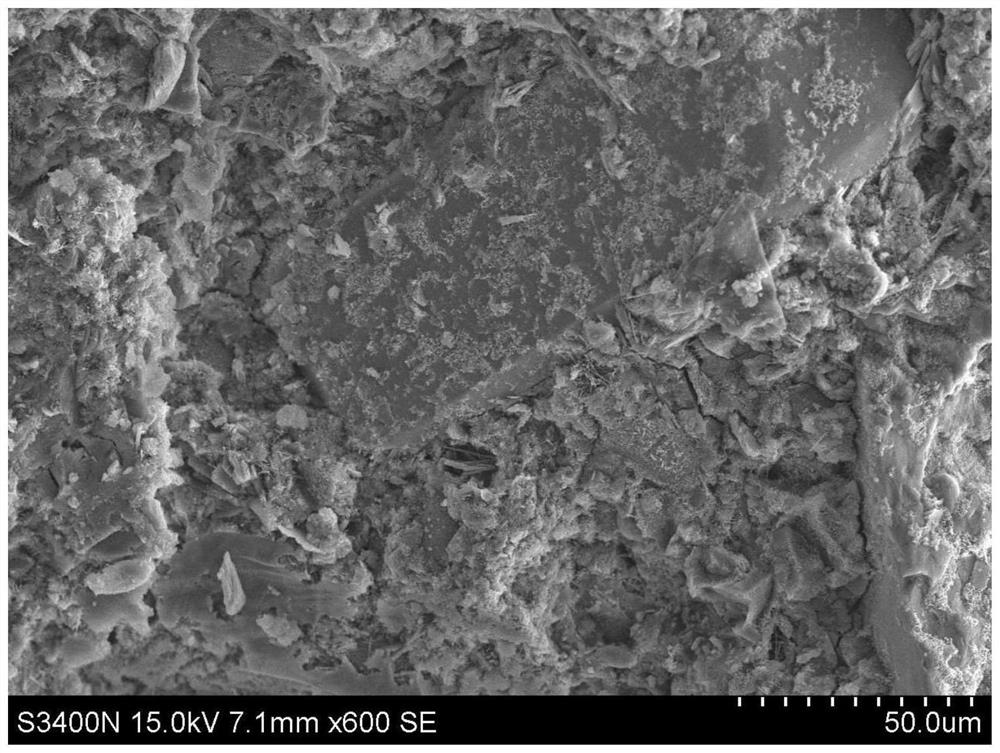

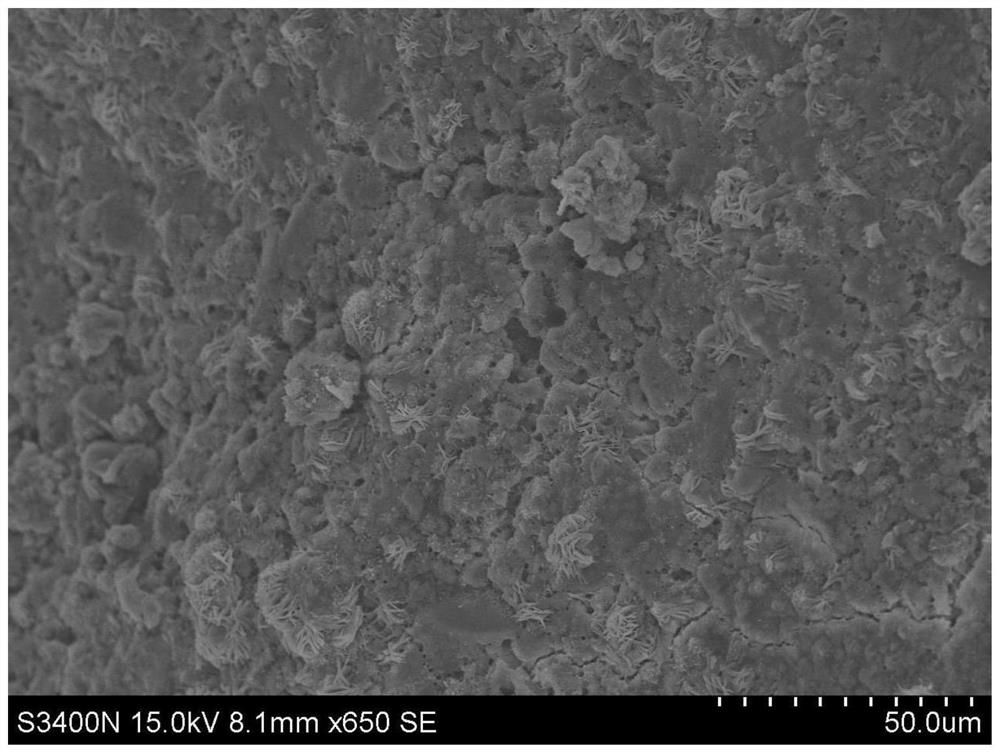

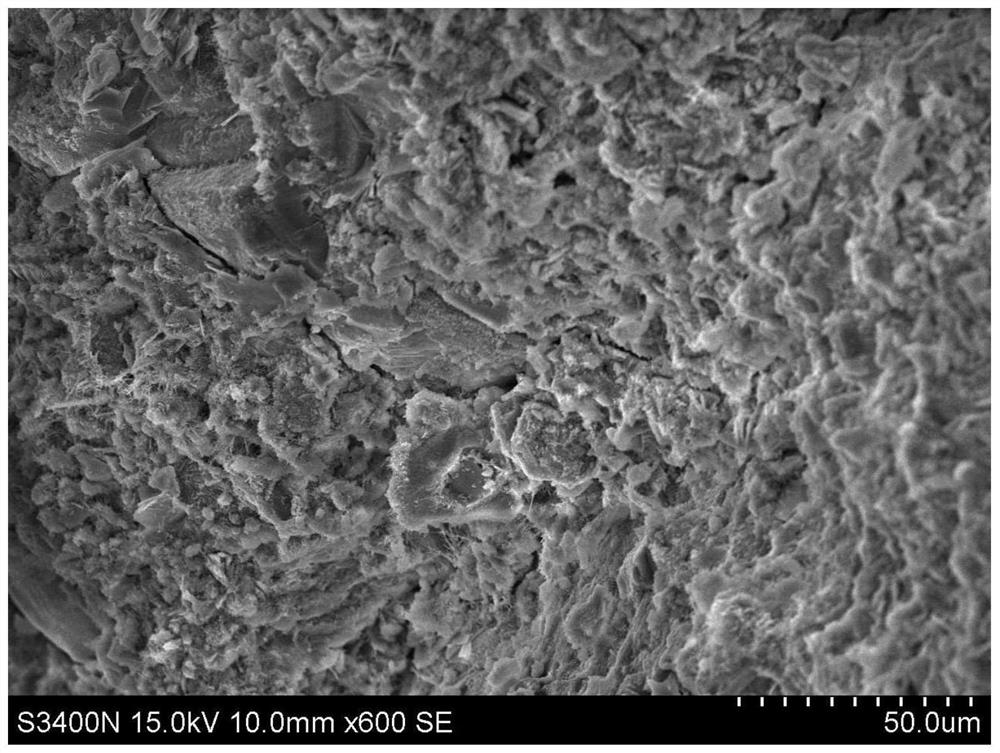

Image

Examples

preparation example Construction

[0042] The preparation method of the recycled rubber mortar of anti-crack insulation described above, comprising the following steps:

[0043] S1: Put the rubber powder into sodium hydroxide solution and soak it for 1-48h after cleaning the surface of the rubber powder with water, remove the surface moisture, and set aside after the rubber powder surface is dried;

[0044] S2: Add the rubber powder treated in step S1 to the grinder, and then add the silane coupling agent, grind for 0.1-10h, so that the rubber powder and the silane coupling agent are in full contact;

[0045] S3: The cement mortar and step S2 rubber powder and silane coupling agent mixture stirred evenly, and then add nano silica, water reducer, cationized fiber, modified sepiolite, water, stirring 0.5-100min, pouring specimens, and at a temperature of 15-40 °C, relative humidity greater than 85% condition maintenance 0.5-5d, continue to maintain after demolding, rubber mortar.

Embodiment 1

[0051] A kind of recycled rubber mortar with anti-crack insulation, in terms of weight: 110 parts of cement mortar, 25 parts of rubber powder, 1.8 parts of silane coupling agent, 8 parts of sodium hydroxide solution, 4 parts of nano silica, 2 parts of superplasticizer, 2 parts of cationized cellulose, and 3 parts of modified sepiolite.

[0052] The rubber powder particle size is 0.5-50 microns.

[0053] The silane coupling agent is KH560.

[0054] The sodium hydroxide concentration is 40% of the aqueous solution.

[0055] The superplasticizer is a polycarboxylic acid high performance superplasticizer.

[0056] The preparation method of the recycled rubber mortar of anti-crack insulation described above, comprising the following steps:

[0057] S1: Put the rubber powder into sodium hydroxide solution for 24h and then clean the surface of the rubber powder with water, remove the surface moisture, and wait for the surface of the rubber powder to dry until the moisture content is less...

Embodiment 2

[0061] A kind of anti-crack insulation recycled rubber mortar, by weight: cement mortar 100 parts, rubber powder 28 parts, silane coupling agent 1.6 parts, sodium hydroxide solution 8 parts, nano silica 3 parts, water reducer 3 parts, cationized cellulose 2 parts, modified sepiolite 3 parts.

[0062] The rubber powder particle size is 0.5-50 microns.

[0063] The silane coupling agent is KH570.

[0064] The sodium hydroxide concentration is 40%.

[0065] The superplasticizer is a polycarboxylic acid high performance superplasticizer.

[0066] The preparation method of the recycled rubber mortar of anti-crack insulation described above, comprising the following steps:

[0067] S1: Put the rubber powder into sodium hydroxide solution for 24h and then clean the surface of the rubber powder with water, remove the surface moisture, and wait for the surface of the rubber powder to dry until the moisture content is less than 20% after the backup;

[0068] S2: Add the rubber powder treate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com