Photoinduced ultrasonic transmitter and manufacturing method thereof

A technology of photoinduced ultrasound and manufacturing method, which is applied in the field of ultrasound, can solve problems such as dispersion of ultrasound directions, random and disordered conduction of heat, disorderly mixing of light-absorbing materials and thermoelastic materials, etc., achieve high light absorption coefficient, and improve photoacoustic conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

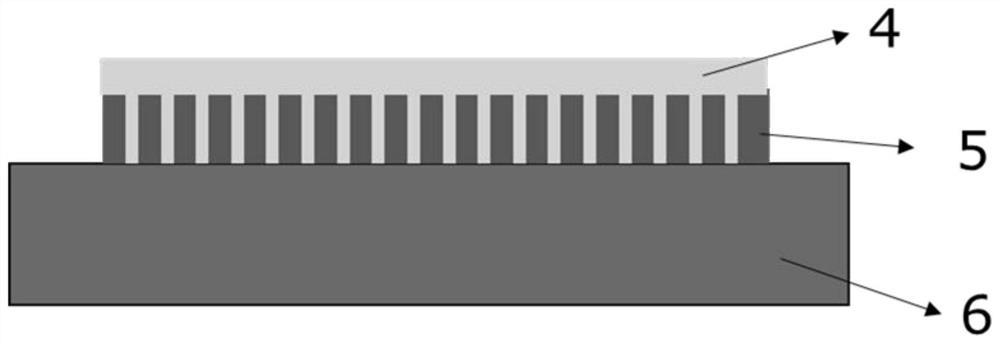

[0027] A structure and a preparation method of a photo-induced ultrasonic transmitter. The device is small in size and simple in structure. The ultrasonic sound pressure generated by the device is high, the frequency is high, the frequency bandwidth is wide and the divergence angle is small. The device is divided into a light absorbing part and a thermal expansion part.

[0028] The composition and production process of the light absorbing part

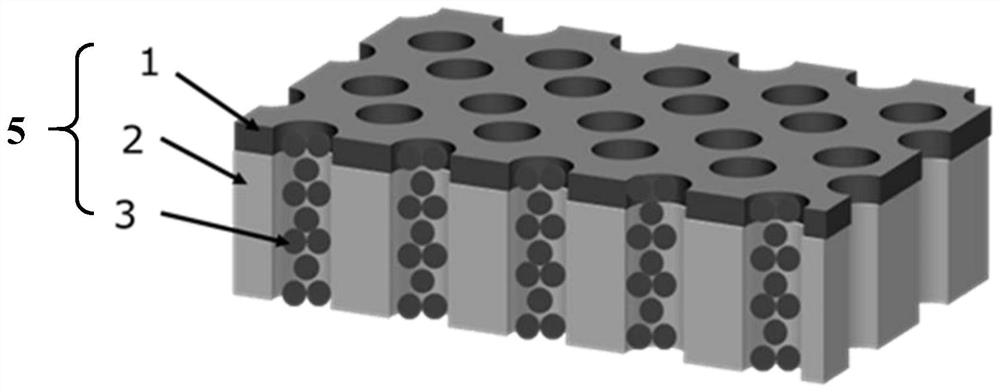

[0029] like Figure 1a Shown is the light-absorbing part of the device, that is, the metal nanoparticle-porous alumina array 5, which includes the metal thin film 1. The porous alumina array adopts the symmetrical double-pass AAO nanometer model DP450-300S-50000 produced by Shenzhen Topology Fine Membrane. Template 2 and metal nanoparticles 3.

[0030] The preparation steps are as follows: an aluminum film is grown on the surface of the porous anodic aluminum oxide by physical vapor deposition, and aluminum nanoparticles are deposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com