Wheel with hardness grade of 360 HB or above for heavy-duty truck and heat treatment method and production method of wheel

A technology of 360HB, heat treatment method, applied in the field of heavy-duty truck wheels and their heat treatment, can solve the problems of low yield, increased production cost, coarse austenite grains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

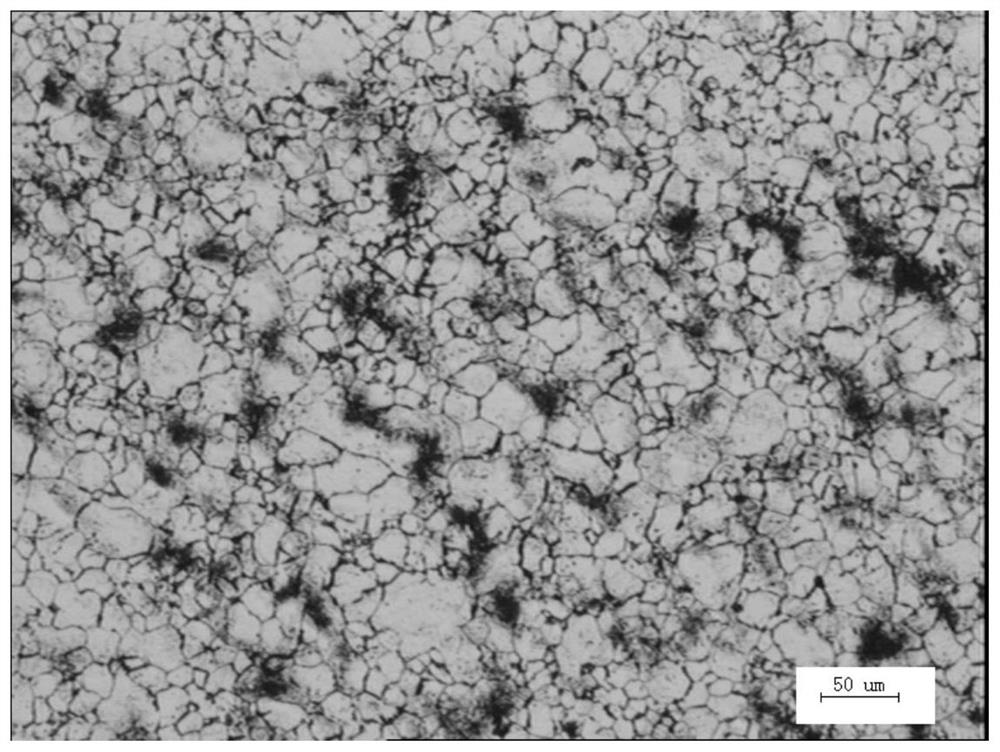

[0046] The chemical composition weight percentages of the wheel steels in Example 1 and Example 2 are shown in Table 1. Both Example 1 and Example 2 were smelted in a 100-ton ultra-high-power electric arc furnace and directly connected after LF+RH refining and vacuum degassing. forging The round billet is cut into ingot, heated and rolled, and heat treated to form a wheel with a diameter of 760mm.

[0047] Example 1

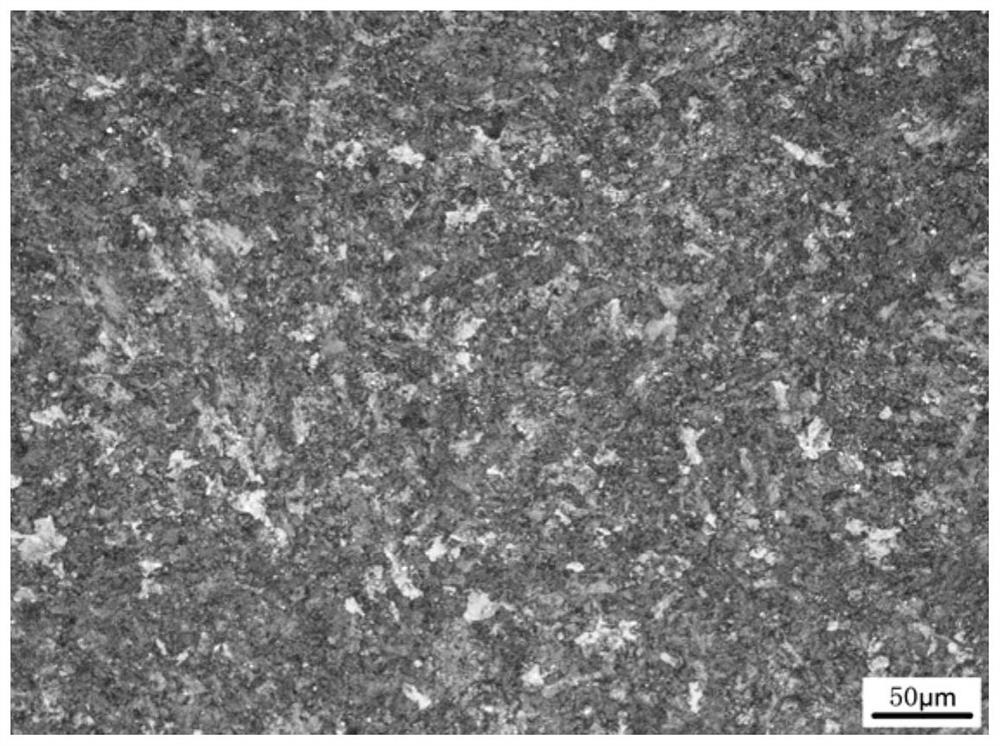

[0048] The molten steel whose chemical composition is shown in Table 1, Example 1, is formed through the electric furnace steelmaking process, the LF furnace refining process, the RH vacuum treatment process, the round billet continuous casting process, the ingot rolling process, the heat treatment process, the processing, and the finished product inspection process. The ingot cutting and rolling process is as follows: the billet is cut into a steel ingot weighing 380kg per piece, heated to 1200° C. for 4 hours, and after the heating is completed, forging prefo...

Embodiment 2

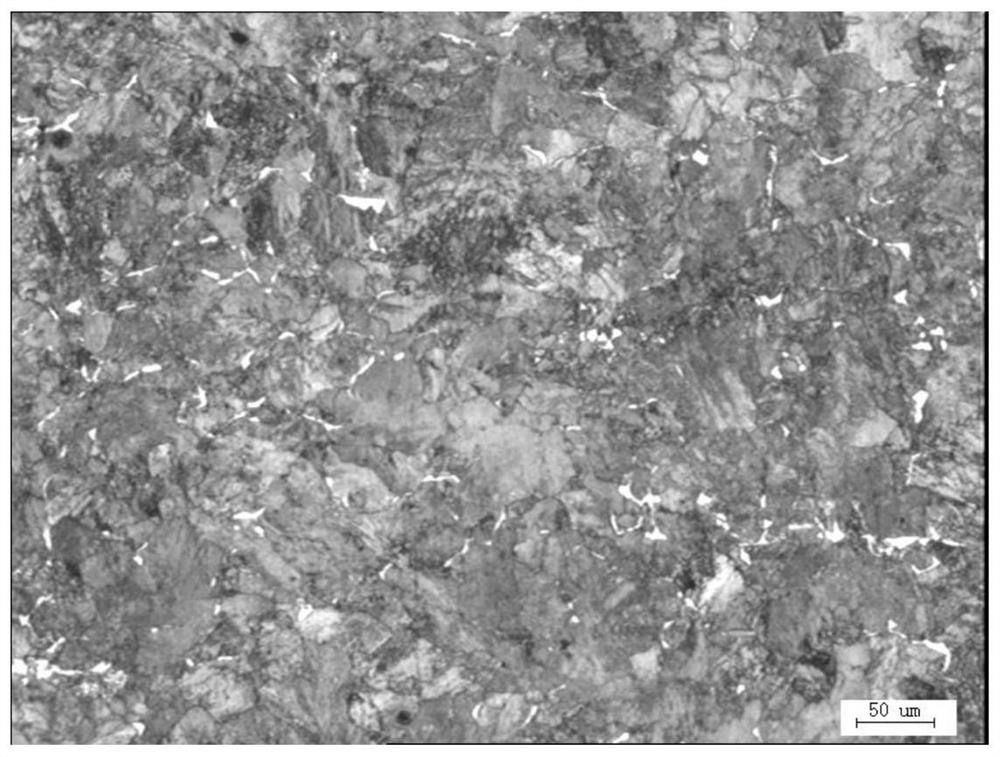

[0052] The molten steel whose chemical composition is shown in Table 1 and Example 2 is formed through the electric furnace steelmaking process, the LF furnace refining process, the RH vacuum treatment process, the round billet continuous casting process, the ingot rolling process, the heat treatment process, the processing, and the finished product inspection process. The ingot cutting and rolling process is as follows: the billet is cut into a steel ingot weighing 380kg per piece, heated to 1200° C. for 4 hours, and after the heating is completed, forging preforming is performed in a 5,000-ton hydraulic press, and then rolled into a 760mm diameter. Wheel; the heat treatment process is as follows: first, after keeping the temperature at 860°C for 2.5 hours, the rim is cooled by spraying water, so that the surface metal of the rim tread is heated to 5°C / s-8°C / s, and the inner metal is heated to 2°C / s-5°C / s. The cooling rate is below 500 °C, and finally tempered at 490 °C for 5....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com