Super-wear-resistant antiviral glaze, ceramic tile and preparation method of ceramic tile

An anti-virus, super wear-resistant technology, applied in the field of ceramic tiles, can solve problems that have not yet appeared, and achieve the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

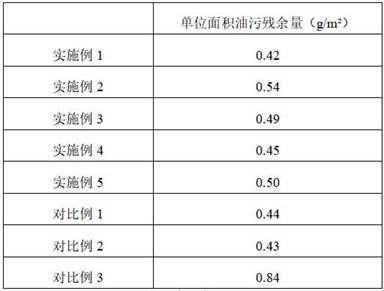

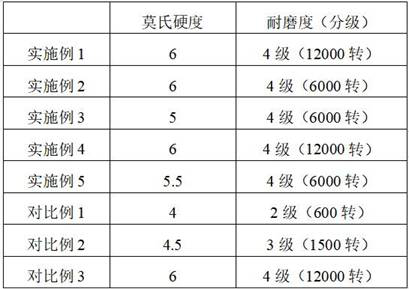

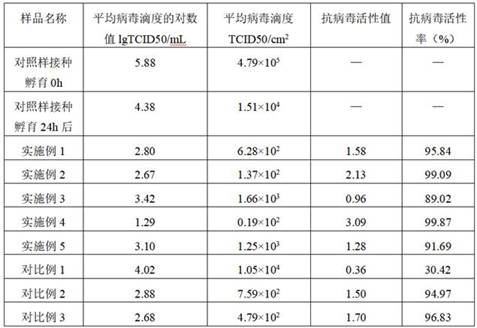

Examples

preparation example Construction

[0034] The preparation method of zinc aluminum phosphate is as follows: put zinc oxide and an appropriate amount of water into a reaction kettle through a material box, and gently stir to obtain a zinc oxide slurry; put aluminum hydroxide and phosphoric acid into the reaction kettle, zinc oxide, aluminum hydroxide, phosphoric acid The molar ratio is (3~7): 1: (10~20), the phosphoric acid concentration is 85wt%, and the constant temperature is 65 o C stirring reaction for 40~60min; then add zinc oxide slurry in batches; transfer the reacted feed liquid to a centrifuge through a pipeline to remove moisture and impurities; dry the solid containing water through a dryer, pass through a pulverizing device and a gas cyclone device to obtain zinc aluminum phosphate.

[0035] Potassium feldspar is ultra-white potassium feldspar with a hardness of 1.5 degrees and a particle size of 200-300 mesh; dolomite is iron-free dolomite with a hardness of 4 degrees; the particle size of quartz is...

Embodiment 1

[0037] The raw materials of the glaze are: 41 parts potassium feldspar, 10 parts calcined kaolin, 8 parts quartz, 17 parts dolomite, 7 parts barium carbonate, 5 parts wollastonite, 10 parts fused dense corundum, 6 parts zinc aluminum phosphate, 3 parts strontium phosphate.

[0038] Follow these steps to prepare ceramic tiles:

[0039] 1. Add the raw materials of the green body into the ball mill, add water, and grind for 5 hours to obtain a slurry. The slurry is passed into the iron removal tank to remove iron filings. Carry out the first aging for 2 days, and then send it into a spray drying bed for drying and granulation to obtain powder particles with a particle size of 0.5 to 1.5 mm. After the second aging for 2 days, it is sent to a brick press and pressed 5 times under 70MPa. Forming, the obtained green body is sent to a drying kiln for drying, and after drying, a dry green body with a moisture content of 1.2 wt% is obtained, and the green body is obtained after cooling...

Embodiment 2

[0044] 30 parts potassium feldspar, 8 parts calcined kaolin, 10 parts quartz, 22 parts dolomite, 10 parts barium carbonate, 7 parts wollastonite, 12 parts fused white corundum, 8 parts zinc aluminum phosphate, 2 parts strontium phosphate.

[0045]Follow these steps to prepare ceramic tiles:

[0046] 1. Add the raw materials of the green body to the ball mill, add water, and grind for 5 hours to obtain a slurry. The slurry is passed into the iron removal tank to remove iron filings. Carry out the first aging for 3 days, and then send it into a spray drying bed for drying and granulation to obtain powder particles with a particle size of 0.5~1.5mm. After the second aging for 2 days, it is sent to a brick press and pressed 4 times under 80MPa. Forming, the obtained green body is sent to a drying kiln for drying, and after drying, a dry green body with a moisture content of 2.2 wt% is obtained. After cooling and surface grinding, a green body is obtained, and the thickness of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com