Preparation method of high-solid-content early-strength polycarboxylate superplasticizer

An early-strength, water-reducing agent technology, applied in the field of concrete admixtures, can solve the problems of increased production cost, labor cost and transportation cost, reduced production efficiency and storage efficiency, and high production cost, so as to shorten the production cycle and improve production efficiency. And the effect of improving storage efficiency, reducing production cost and transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

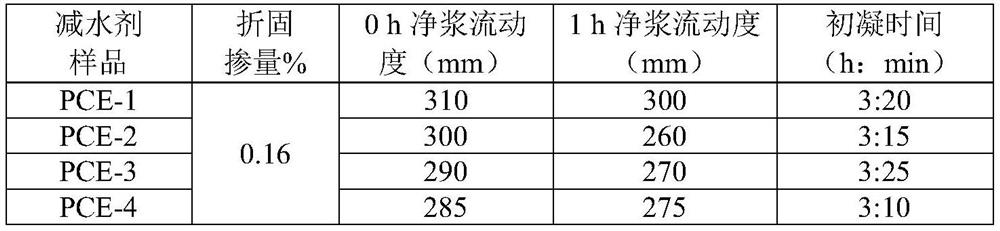

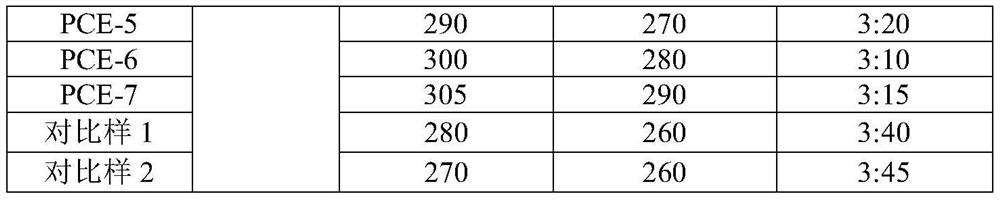

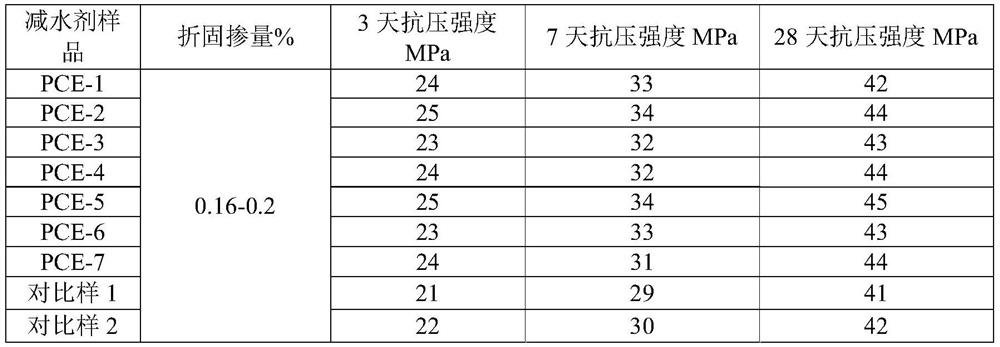

Examples

Embodiment 1

[0038] In a 250mL four-necked flask equipped with a stirrer and a thermometer, add 40mL of water, 40g of HPEG2400, and 0.24g of sodium methacrylate sulfonate in turn, and the temperature is controlled at 10 °C; The aqueous solution B (mass fraction 4%) of 0.18 g of mercaptoethanol and 0.025 g of vitamin C was slowly pumped and added dropwise to the above-mentioned four-necked flask; evenly stirred for 5 min, the aqueous solution A (mass fraction 15 %) was slowly pumped dropwise into the above-mentioned four-necked flask. Solution A was added dropwise for 3 hours, solution B was added dropwise for 3.5 hours, and the reaction temperature was controlled at 25°C. After the dropwise addition was completed, the temperature was kept for 0.5h, and 5.5g of triethanolamine was added to the four-necked flask at one time, and the water was added to the total mass of the raw material to 100g, and then cooled to room temperature to obtain a high-solid content early-strength polycarboxylate ...

Embodiment 2

[0040]In a 250mL four-necked flask equipped with a stirrer and a thermometer, 40mL of water, 43g of HPEG3000, and 0.23g of sodium propylene sulfonate were added in turn, and the temperature was controlled at 8°C; after stirring evenly, 0.5g of benzoyl peroxide solution was gradually added dropwise to the flask, After 10 min, the aqueous solution B (mass fraction 6%) containing 0.18 g of thioglycolic acid and 0.025 g of ferrous sulfate was added to the above-mentioned four-necked flask at one time; evenly stirred for 5 min, the aqueous solution A (mass fraction 15%) containing 3 g of acrylic acid was added once Add to the above four-necked flask. The reaction was performed for 2 hours, and the temperature was controlled at 28 °C. After the completion of the thermal insulation and aging for 0.6 hours, the reaction was cooled to room temperature. 6 g of diethanol monoisopropanolamine was added to the four-necked flask at one time, and the water was added to the total mass of the r...

Embodiment 3

[0042] In a 250mL four-necked flask equipped with a stirrer and a thermometer, add 40mL of water, 45g of TPEG2400, 0.25g of sodium methacrylate sulfonate in sequence, and the temperature is controlled to 8 °C; The aqueous solution B (mass fraction 8%) of 0.2 g of propionic acid and 0.03 g of vitamin C was slowly pumped and added dropwise to the above-mentioned four-necked flask; evenly stirred for 5 min, the aqueous solution A (mass fraction of 2 g of methacrylic acid and 2 g of maleic acid) was stirred. Fraction 15%) was slowly pumped dropwise into the above-mentioned four-necked flask. Solution A was added dropwise for 3h, solution B was added dropwise for 3.5h, and the reaction temperature was controlled at 30°C. The dropwise addition was completed, heat preservation and aging for 0.8h, cooled to normal temperature, and 5g of hydroxyethyl diisopropanolamine was added to the four-necked flask at one time, and the water was added to the total mass of the raw material 100g, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com