Low-odor pp/as/pok ternary composite resin, cosmetic packaging material and preparation method thereof

A ternary composite and cosmetics technology, which is applied in the field of low-odor PP/AS/POK ternary composite resin, cosmetic packaging materials and its preparation, can solve problems such as dependence on active functional groups, poor compatibility, and modification of polypropylene molecular chains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

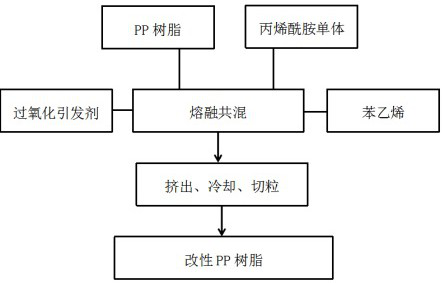

[0024] Preparation of modified PP resin: melt blending PP resin, acrylamide monomer, dibenzoyl peroxide, and styrene with a mass ratio of 10:1:0.1:0.1 at 150° C. for 8 minutes, extruding, and pelletizing, Acrylamide-modified PP resin was obtained.

Embodiment 2

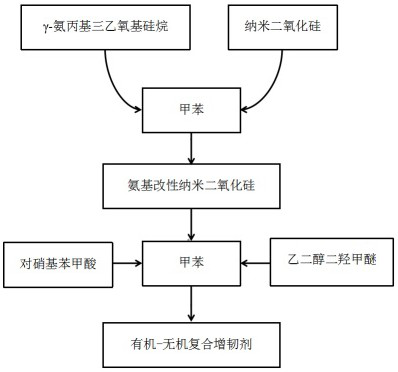

[0026] Preparation of organic-inorganic composite toughening agent: Step 1: Add γ-aminopropyltriethoxysilane to toluene, mix and disperse, then add nano-silica, react at 78°C for 2h, filter, Rinse three times with absolute ethanol and dry at 50°C to obtain amino-modified nano-silica;

[0027] Wherein, the mass ratio of toluene, γ-aminopropyltriethoxysilane and nano-silica in the first step is 50:10:3;

[0028]The second step: place amino-modified nano-silica and ethylene glycol dimethylol ether in toluene, add catalyst p-nitrobenzoic acid, react at 85°C for 8h, filter with suction, wash with absolute ethanol for 3 times, 50 drying at ℃ to obtain an organic-inorganic composite toughening agent;

[0029] Wherein, the mass ratio of amino-modified nano-silica, ethylene glycol dimethylol ether, toluene, p-nitrobenzoic acid in the second step is 15:10:50:1.5;

[0030] Wherein, p-nitrobenzoic acid is an aqueous solution of p-nitrobenzoic acid with a mass percentage content of 10% (...

Embodiment 3

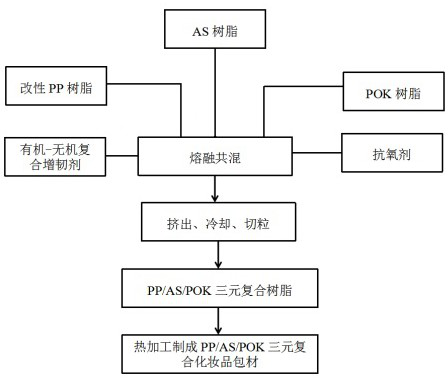

[0032] Preparation of PP / AS / POK ternary composite resin: acrylamide-modified PP resin, AS resin, POK resin, organic-inorganic composite toughener and antioxidant with a mass ratio of 10:10:10:1:1 1010 was melt-blended at 210°C for 6 minutes, and then extruded, cooled and pelletized to obtain PP / AS / POK ternary composite resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com