MOCVD (Metal Organic Chemical Vapor Deposition) equipment for ZnO film growth

A thin film growth and equipment technology, applied in mechanical equipment, coating, vibration suppression adjustment and other directions, can solve the problems of temperature instability, low applicability, temperature feedback, etc., to improve balance and uniformity, provide use safety, The effect of reducing the influence of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

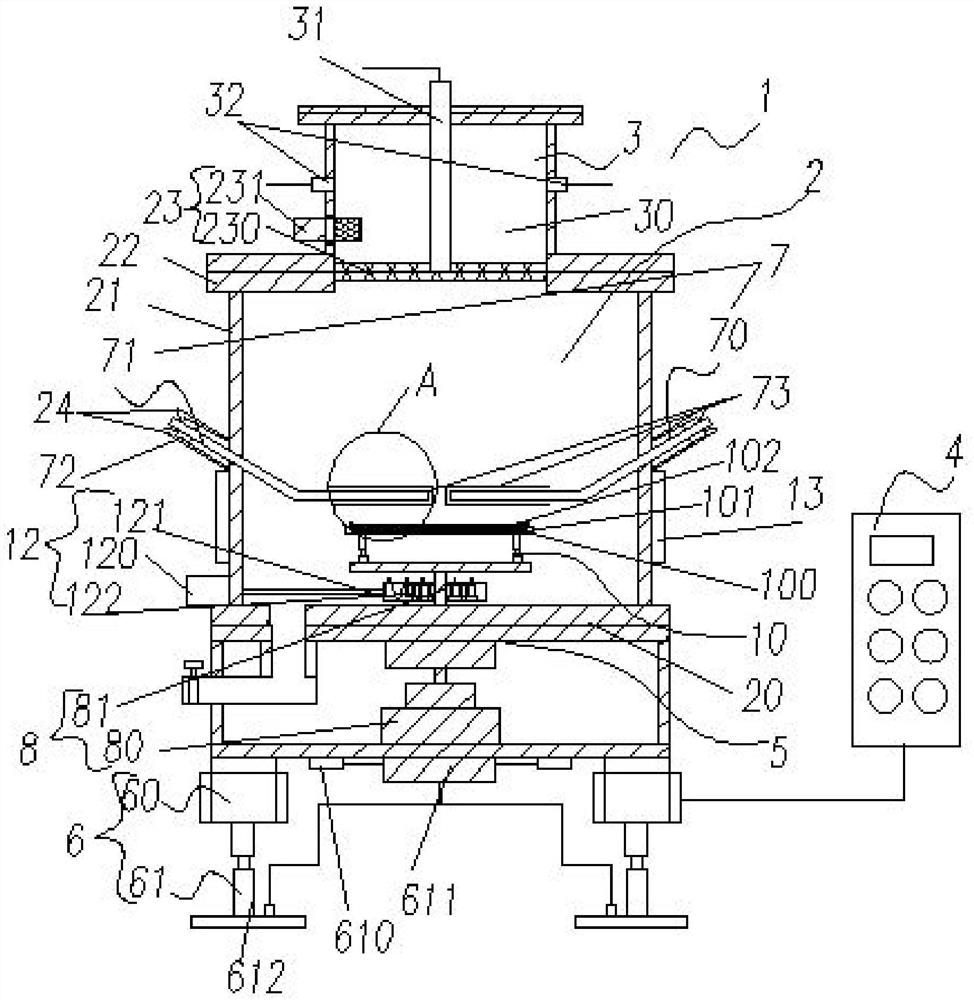

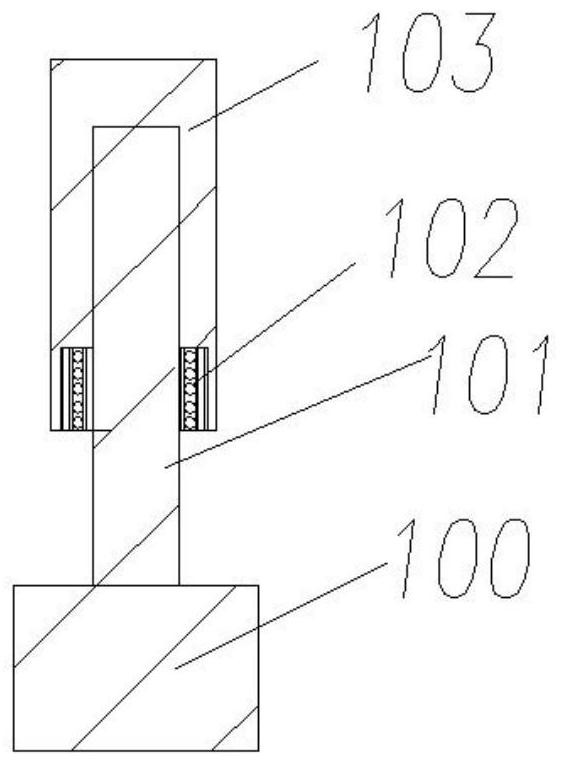

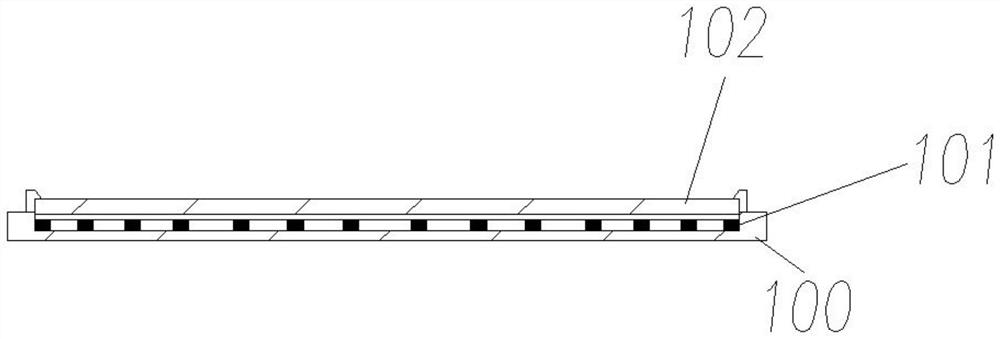

[0026] example, see appendix Figure 1 to Figure 7, a kind of MOCVD equipment for ZnO thin film growth comprises MOCVD equipment body 1, described MOCVD equipment body 1 comprises reaction chamber 2, gas transport system 3, control system 4, reaction processing system 5 and vibration reduction balance system 6, described gas The transportation system 3 is arranged above the reaction chamber 2, the vibration damping and balance system 6 is arranged below the reaction chamber 2, the reaction chamber 2 is provided with a reaction chamber, and the reaction processing system 5 is arranged in the reaction chamber 2. In the reaction chamber, the reaction processing system 5 includes a spray gun device 7, a rotating assembly 8, a placing platform 9 and a lifting mechanism 10. The placing platform 9 is arranged on the rot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap