Vanadium disulfide-vanadium tetrasulfide nano material with lamellar self-assembly structure, preparation method thereof and rechargeable battery with excellent rate capability

A nanomaterial, vanadium disulfide technology, applied in the field of making rechargeable batteries, can solve the problems that the active material cannot be fully contacted with the electrolyte, the performance cannot be fully utilized, and the discharge capacity is unstable. Low cost and the effect of improving charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

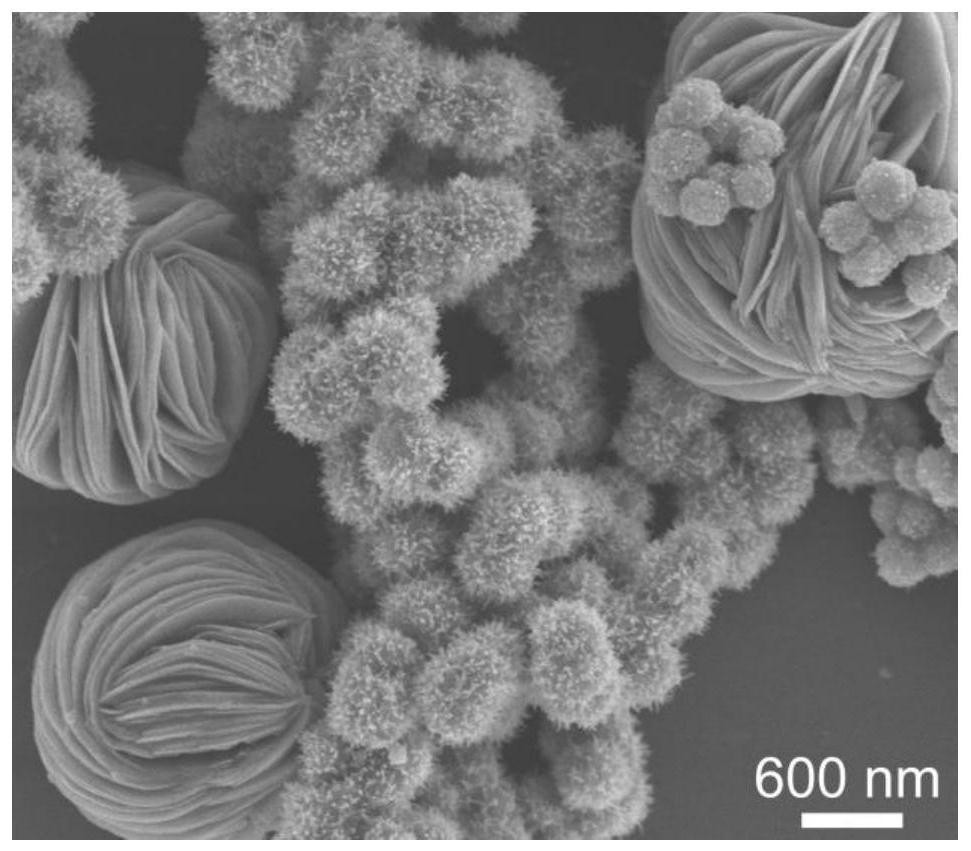

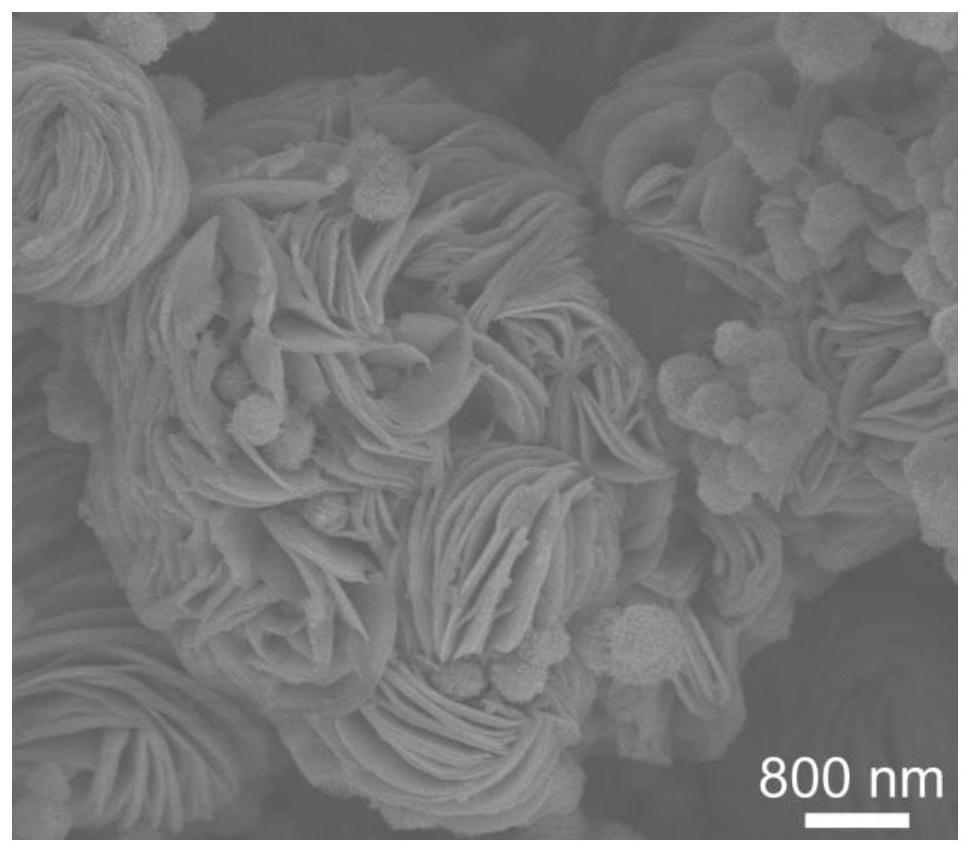

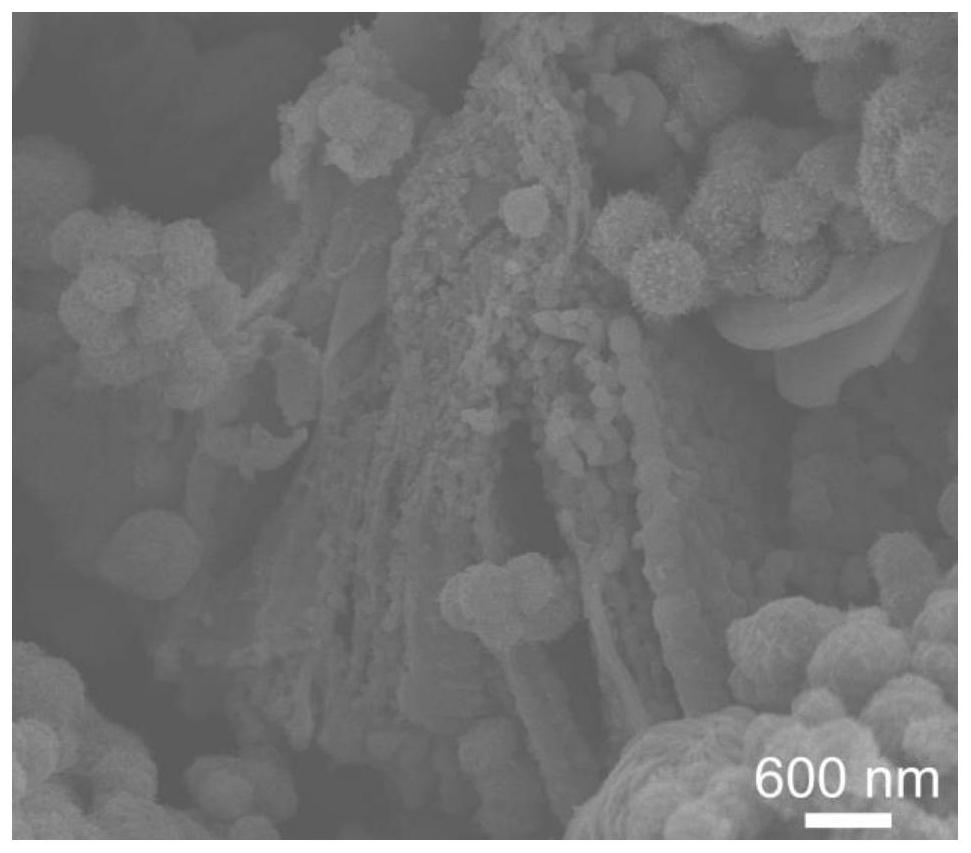

[0123] A lamellar self-assembled structure VS 2 @VS 4 The method for preparing nanomaterials includes the following steps:

[0124] 1) Put 0.4212g NH 4 VO 3 Disperse in 30 mL of water in a 60°C hot water bath, stir vigorously, with a stirring speed of 800 rpm and a time of 0.5 h, to dissolve it to form a mixed solution;

[0125]2) Add 0.03mol of thioacetamide (TAA) into step 1), stir, the stirring speed is 600rpm, and the time is 1h to form a mixed solution, and 3.6mL of concentrated ammonia water with a mass concentration of 25% is transferred into the mixed solution. Stir, the stirring time is 1h under the condition of 800rpm, the solution is transferred to a 50mL polytetrafluoroethylene reaction kettle for hydrothermal reaction, the reaction is 180°C, the reaction time is 8h, the reaction is over, and the centrifugal washing is performed at 8000r and the time is 1min; Washed 6 times with water and 2 times with ethanol, and dried at 60 °C for 12 h to obtain VS 2 Nanoshe...

Embodiment 2

[0130] A rechargeable battery with excellent rate performance, using the above-mentioned lamellar self-assembly structure VS 2 @VS 4 Nanomaterials are used as active materials to prepare aluminum-ion battery cathodes, and then to prepare rechargeable aluminum-ion batteries.

[0131] Specifically: the lamella self-assembled structure VS prepared based on Example 1 2 @VS 4 Nanomaterials are used as active substances, and the rose-shaped VS prepared based on Example 1 will be 2 The nanosheet material is used as the active material of the comparative material. The above two active materials are uniformly mixed with conductive carbon black and PVDF according to the ratio of 7:2:1, and magnetically stirred for 8 hours to uniformly disperse them in NMP. The slurry was coated on carbon paper with a coater, placed in a vacuum drying oven at 80 °C, dried for 24 hours, and pressed with a tablet machine, and then cut into a small circular shape with a tablet machine. electrode sheet; ...

Embodiment 3

[0136] A lamellar self-assembled structure VS 2 @VS 4 The method for preparing nanomaterials includes the following steps:

[0137] 1) Put 0.4212g NH 4 VO 3 Disperse in 30 mL of water in a 60°C hot water bath, stir vigorously with a stirring speed of 800 rpm and a time of 0.5 h to dissolve to form a mixed solution;

[0138] 2) Add 0.03mol of thioacetamide (TAA) into step 1), stir, the stirring speed is 600rpm, and the time is 1h to form a mixed solution, and 3.6mL of concentrated ammonia water with a mass concentration of 25% is transferred into the mixed solution. Stir, conduct magnetic stirring at 800 rpm for 1 h; transfer the solution to a 50 mL polytetrafluoroethylene reaction kettle for hydrothermal reaction, react at 180 ° C, the reaction time is 12 h, the reaction is over, centrifugal washing, the rotation speed is 8000 r and the time is 1 min; first wash with water 6 times, washed with ethanol twice, drying temperature 60 ℃, time 12h, to obtain rose-shaped VS 2 Na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com