Multidirectional stretchable electric heating anti-icing and deicing material as well as preparation method and application thereof

A technology of electric heating and electric heating film, applied in the direction of heating element materials, ohmic resistance heating, ohmic resistance heating parts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides the preparation method of the multidirectional stretchable electric heating anti-icing material according to the above technical solution, comprising the following steps:

[0042] Mixing the elastic matrix, the nano conductive filler and the organic solvent to obtain the stretchable electric heating material dispersion;

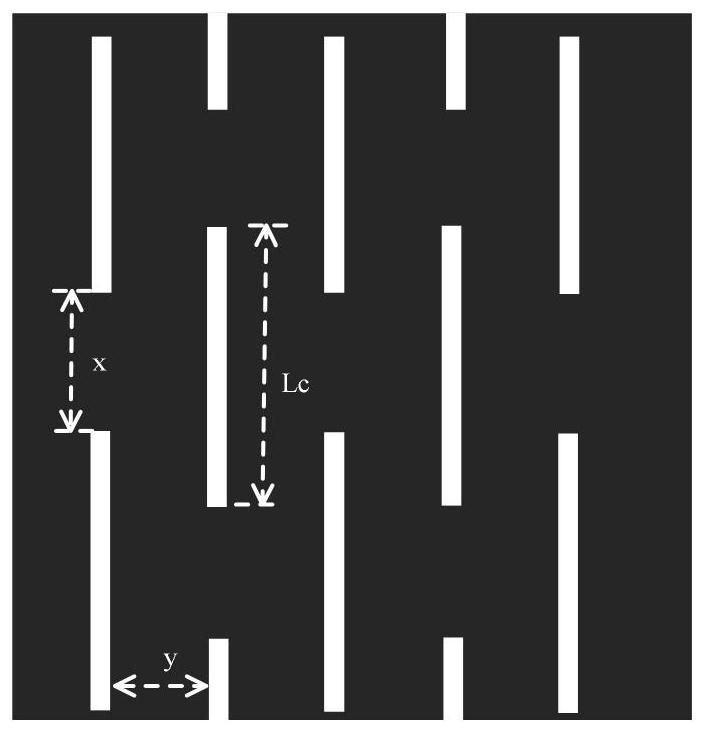

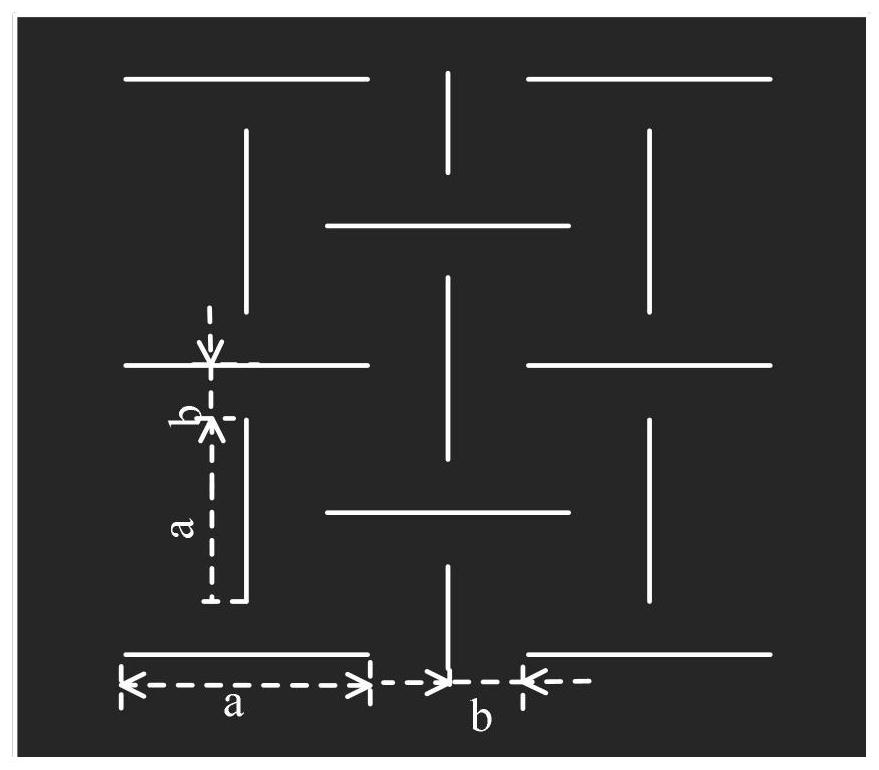

[0043] Arrange parallel flexible stretchable electrodes on the substrate, apply the stretchable electric heating material dispersion on the surface of the substrate on which the flexible stretchable electrodes are arranged, and then perform curing and demolding in sequence to obtain a multidirectional stretchable electric heating material. Heat up anti-icing material.

[0044] In the invention, the elastic matrix, the nano conductive filler and the organic solvent are mixed to obtain the stretchable electric heating material dispersion. In the present invention, the mixing method is preferably as follows: adding nano-con...

Embodiment 1

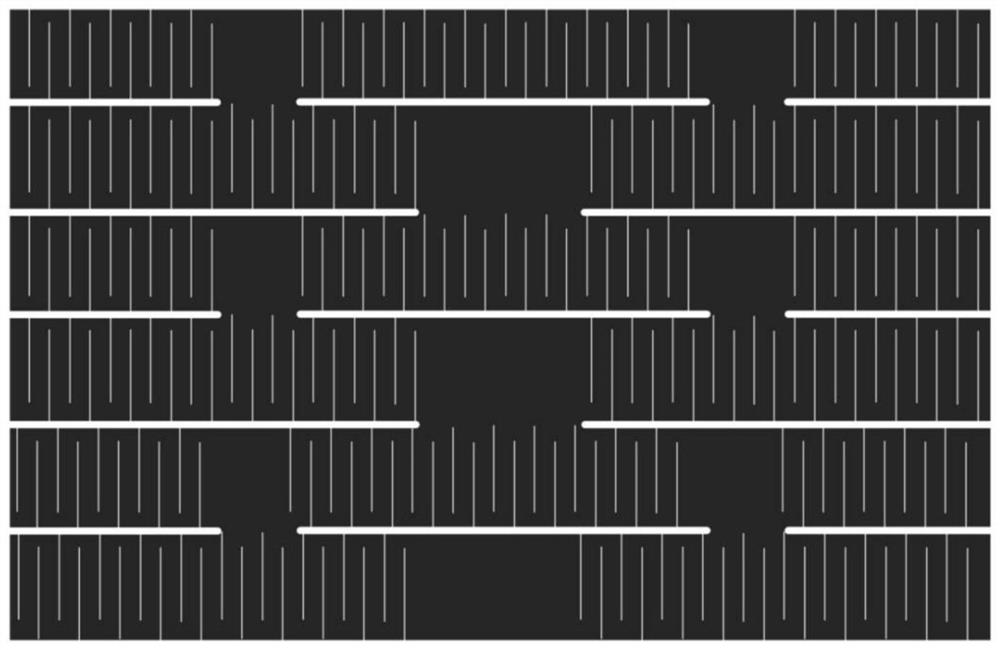

[0050] A multidirectional stretchable electric heating anti-icing material, the preparation method is as follows:

[0051] The commercial spandex stretchable fiber cloth was pre-stretched for O 2 Plasma treatment, and then silver-plated on the pretreated fiber cloth by electroless plating to obtain an electroless silver-plated fiber cloth as a flexible stretchable electrode; the process of electroless plating is: (1) configure silver ammonia solution; ( 2) configure reducing solution, weigh glucose and tartaric acid into a beaker, add deionized water, then heat on an electric furnace, boil for 10min, and cool to room temperature; add absolute ethanol to the obtained solution, then add water and dilute to 1L ( Preheat to 30°C when using); (3) put O 2 The plasma-treated fiber cloth is pre-stretched and immersed in the prepared silver ammonia solution. After soaking for 30 minutes, the prepared reducing solution is added dropwise, and magnetic stirring is used; (4) the obtained ...

Embodiment 2

[0057] A multidirectional stretchable electric heating anti-icing material, the preparation method is as follows:

[0058] Firstly, the silicone rubber film is prepared by casting and demoulding, the silicone rubber film is pre-stretched and the uncured silicone rubber latex is added dropwise, and then the carbon nanotube film is attached to the side of the pre-stretched silicone base on which the silicone rubber latex is added. The surface is released after curing to obtain a carbon nanomembrane-based flexible and stretchable electrode with a micro-folded structure;

[0059] In the elastic matrix material styrene-butadiene rubber, nano conductive filler graphene and organic solvent toluene are added, followed by mechanical stirring and ultrasonic dispersion to obtain a stretchable electric heating material dispersion; the mass of the elastic matrix is 10% of the mass of the organic solvent, The mass of nano conductive filler is 10% of the mass of styrene-butadiene rubber; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com