Zr-containing multi-element nickel-based brazing filler metal, preparation method and brazing method of Zr-containing multi-element nickel-based brazing filler metal

A brazing method and technology of brazing materials, which are applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as thermal damage, chemical erosion, and diamond graphitization, and achieve the effects of improving mechanical properties, inhibiting growth, and lowering melting point Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

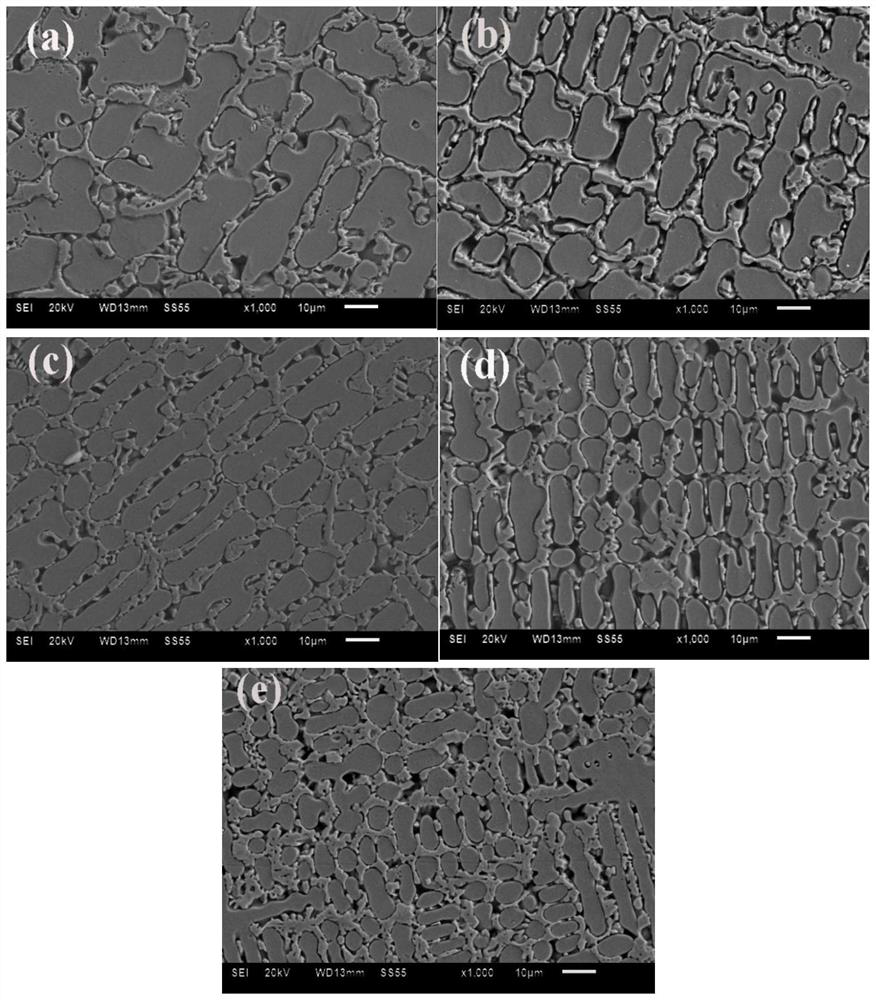

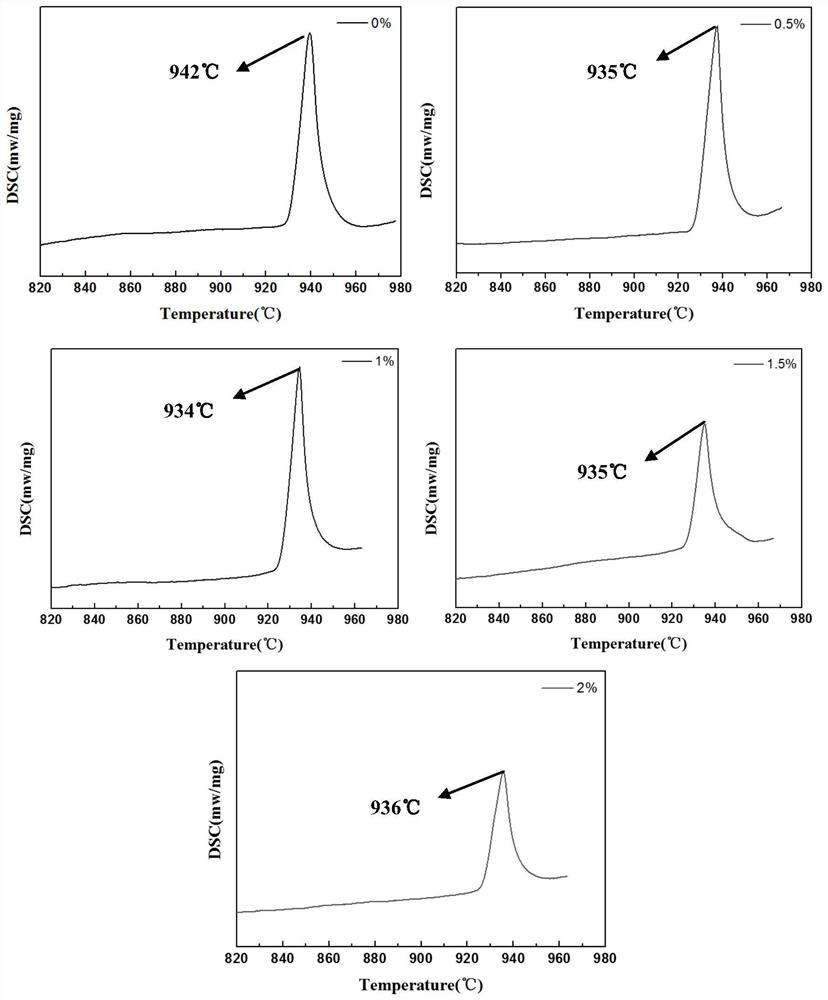

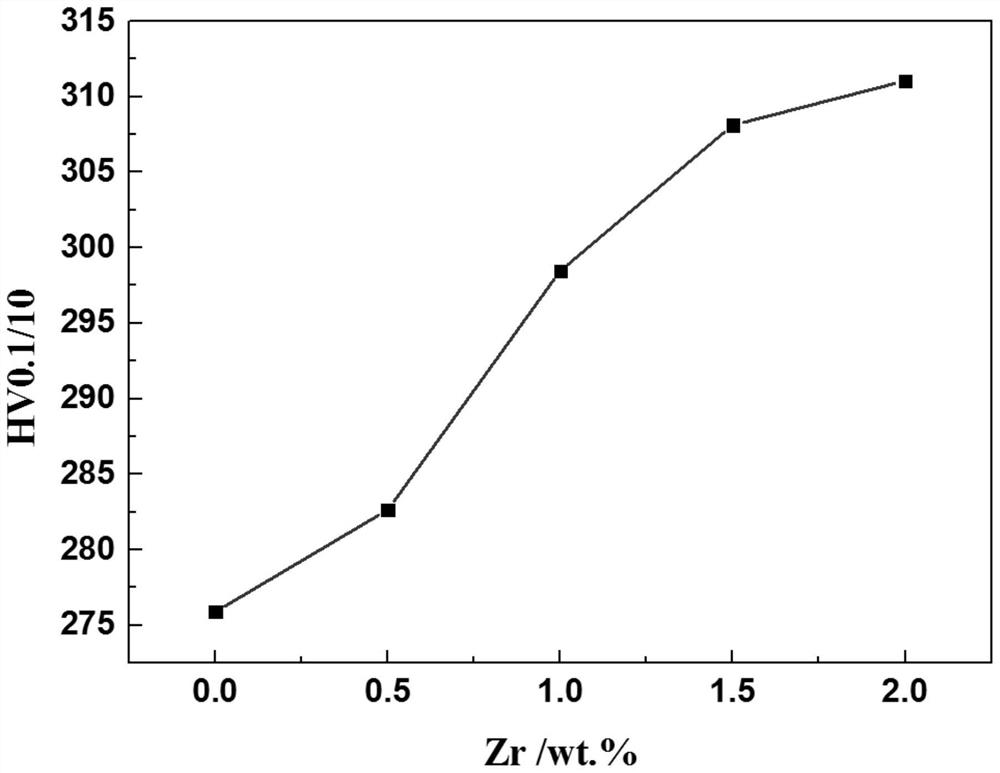

Embodiment 1

[0042] Components (mass percentage): Ni: 55.0%, Cr: 15.0%, Si: 5.0%, Cu: 20.0%, Sn: 5.0%, Zr: 0%.

[0043] Preparation:

[0044] (1) Weigh the corresponding elemental metal raw materials according to the mass percentage of each element: after polishing the surface oxide scale and impurities of the corresponding elemental metal raw materials with sandpaper, weigh the corresponding 5.5gNi, 1.5g Cr, 0.5g Si, 2g Cu, 0.5g Sn, And ultrasonic cleaning with acetone for about 10min, drying for use.

[0045] (2) Place the dried metal raw material in a vacuum electric arc furnace, and pump it to a vacuum degree of 1×10 -3 , and pass Ar gas as a protective gas, put each metal raw material into the crucible from top to bottom according to the melting point, and the Sn metal is at the bottom, effectively avoiding the volatilization of the raw material during melting; then melting the alloy to make the solder The alloy is remelted-solidified-remelted-solidified 3-4 times, and the brazing f...

Embodiment 2

[0051] Components (mass percentage): Ni: 54.5%, Cr: 15.0%, Si: 5.0%, Cu: 20.0%, Sn: 5.0%, Zr: 0.5%.

[0052] (1) Weigh the corresponding elemental metal raw materials according to the mass percentage of each element: after polishing the surface oxide scale and impurities of the corresponding elemental metal raw materials with sandpaper, weigh the corresponding 5.45g Ni, 1.5g Cr, 0.5g Si, 2g Cu, 0.5g Sn and 0.05g Zr, ultrasonically cleaned with acetone for about 10min, and dried for later use.

[0053] (2) Place the dried metal raw material in a vacuum electric arc furnace, and pump it to a vacuum degree of 1×10 -3 Pa, and Ar gas was introduced as a protective gas, and each metal raw material was put into the crucible from top to bottom according to the melting point, and the Sn metal was at the bottom, which effectively avoided the volatilization of the raw materials during melting; The material alloy is remelted-solidified-remelted-solidified 3 to 4 times, and the solder all...

Embodiment 3

[0059] Components (mass percent): Ni: 54.0%, Cr: 15.0%, Si: 5.0%, Cu: 20.0%, Sn: 5.0%, Zr: 1.0%.

[0060] (1) Weigh the corresponding elemental metal raw materials according to the mass percentage of each element: after polishing the surface oxide scale and impurities of the corresponding elemental metal raw materials with sandpaper, weigh the corresponding 5.4g Ni, 1.5g Cr, 0.5g Si, 2g Cu, 0.5g Sn and 0.1g Zr, and ultrasonically cleaned with acetone for about 10min, and dried for later use.

[0061] (2) Place the dried metal raw material in a vacuum electric arc furnace, and pump it to a vacuum degree of 1×10 -3 Pa, and Ar gas was introduced as a protective gas, and each metal raw material was put into the crucible from top to bottom according to the melting point, and the Sn metal was at the bottom, which effectively avoided the volatilization of the raw materials during melting; The material alloy is remelted-solidified-remelted-solidified 3 to 4 times, and the solder allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com