Preparation method of degarelix crude peptide

A technology of Rick crude peptide and Rick peptide, applied in the field of preparation of Degarelix crude peptide, can solve the inevitable safety hazards of methyl tert-butyl ether, unfriendly industrial scale production, environmental and operator hazards To achieve the effect of improving the quality of the production and operating environment, avoiding repeated centrifugation steps, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049]The invention discloses a preparation method of degarelix crude peptide, and those skilled in the art can learn from the content of this article and appropriately improve the process parameters to achieve. It should be particularly pointed out that all similar substitutions and modifications are obvious to those skilled in the art, and they are deemed to be included in the present invention. The method and application of the present invention have been described through the preferred embodiments, and it is obvious that relevant persons can make changes or appropriate changes and combinations of the methods and applications described herein without departing from the content, spirit and scope of the present invention to achieve and Apply the technology of the present invention.

[0050] The invention provides a degarelix crude peptide precipitation method, the specific steps are as follows:

[0051] 1) Cleavage degarelix peptide resin, filter to remove resin, obtain dega...

Embodiment 1

[0069] Example 1: Cleavage of degarelix resin

[0070] Take 20.0 g of degarelix peptide resin obtained by the solid-phase synthesis method of the applicant's patent (CN 102329373A) and add it to a 500 mL single-neck flask, and add 160 mL of pre-prepared lysis solution (TFA:H 2 O=95:5), cracked at room temperature for 2 hours, filtered the resin, washed with a small amount of TFA, combined the filtrates, and the filtrate volume was 160 mL.

Embodiment 2

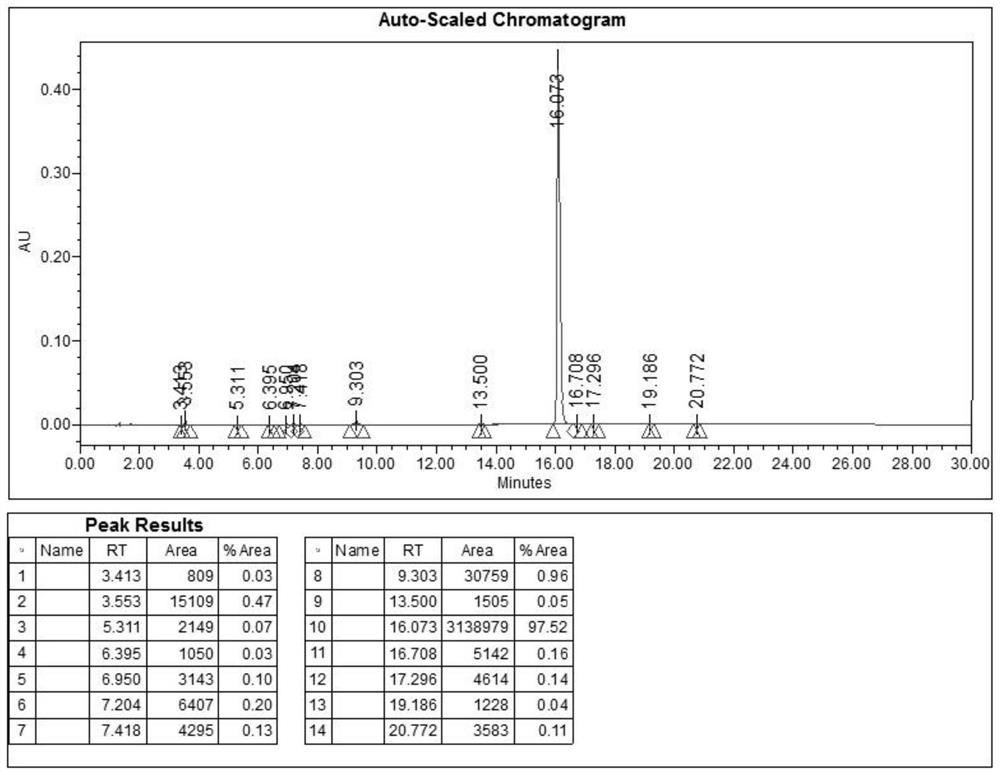

[0072] Add 20 mL of degarelix lysate filtrate obtained in Example 1, pH=0 directly (without concentration, i.e. 100% lysate volume) into water (40mL) of 2 times the lysate filtrate volume to dilute, and separate out a mass Viscous solid, stirred with glass rod, the solid gradually dispersed in the transparent water phase in granular form, continued magnetic stirring, the solid particles became finer, and the solution was cloudy white slurry. The filter cake was obtained by filtration, because the crude peptide needed to be further dissolved in water and acetonitrile during the next purification, so the obtained filter cake was vacuumed for 15 minutes to obtain degarelix white solid crude peptide, wet weight 2.28g, after inspection, degarelix was obtained. The purity is 97.52% and the content is 49.2%, so the solid precipitation rate is 98.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com