Conductive hydrogel as well as preparation method and application thereof

A conductive hydrogel and material technology, which is applied in the field of conductive hydrogel and its preparation, can solve the problems that cannot meet the actual situation and the performance of conductive hydrogel is single, and achieve the problem of shortening the unevenness of crosslinking and shortening the crosslinking The time, the effect of improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1 Investigating the influence of different monomer ratios on the gelation and properties of hydrogels

[0063] 1. The monomer ratio is 1:1

[0064] At room temperature, weigh 0.9411g 1-vinylimidazole, 1.0808g sodium methacrylate, 210μL polyethylene glycol diacrylate (about 0.2% of the total monomer molar), 5.5μL 2-hydroxy-2- Methyl-1-phenylacetone (about 0.2% of the total monomer mole), 0.07g of zinc chloride hexahydrate, placed in a clean 50ml beaker, added 10ml of distilled water and placed on a magnetic workbench at 800r / min stirring speed for 25min. The above solution after being mixed evenly was injected into two 10*10cm glass splints with a 5mL syringe, and the thickness between the glass plates was 0.1cm. After the solution was injected, the small air bubbles in the glass plate were evacuated, and then the glass plate was placed in a UV curing oven with a wavelength of 365 nm for 35 minutes. After the temperature of the glass plate was cooled to room t...

Embodiment 2

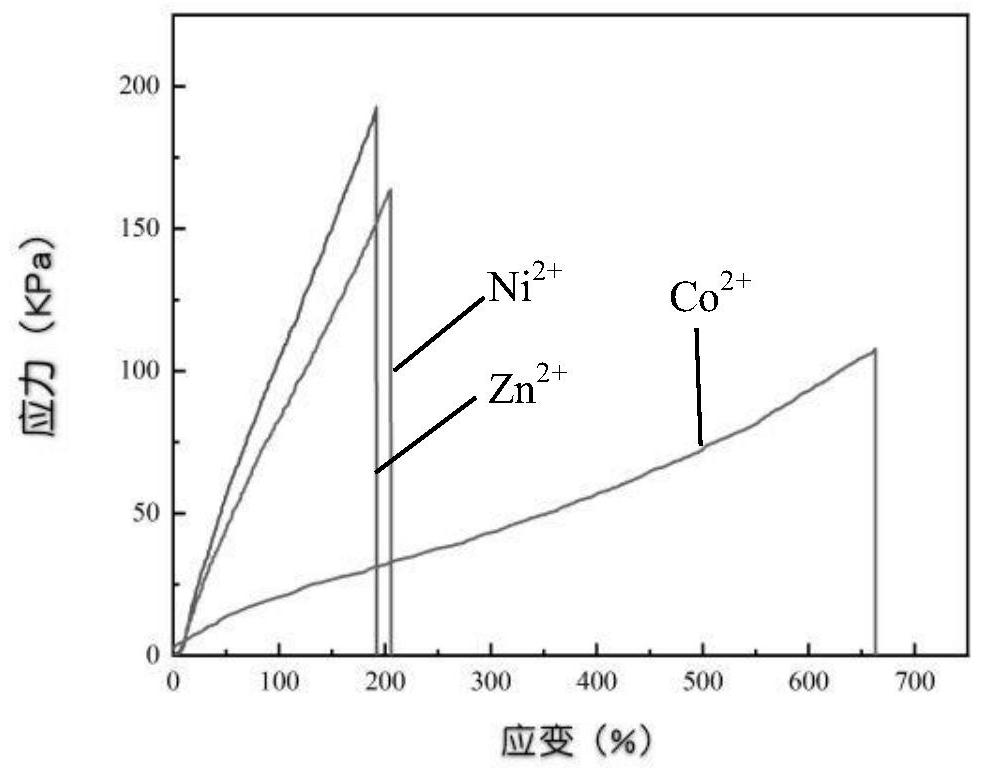

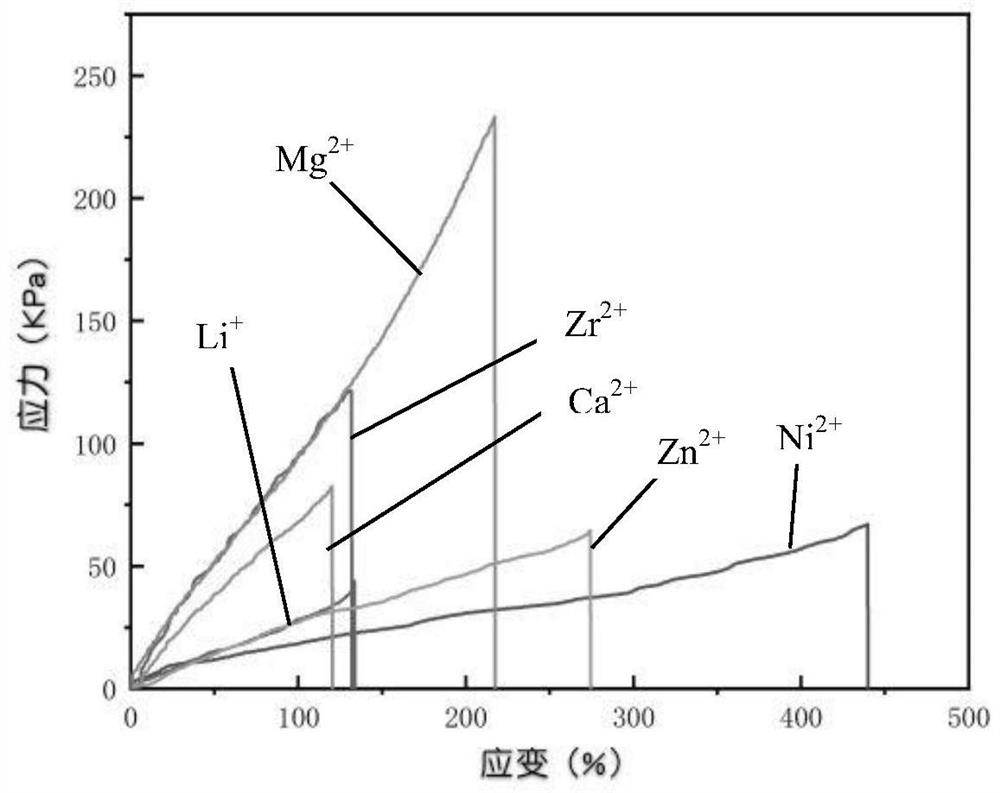

[0071] Example 2 Investigate the influence of different metal ions on the gelation and properties of hydrogels

[0072] The specific experimental process is basically the same as the preparation method of sample D4, the difference is that different types of metal ions of the same concentration are changed. The specific conditions are shown in Table 1. The obtained conductive hydrogels corresponding to metal coordination are recorded as samples J1-J3.

Embodiment 3

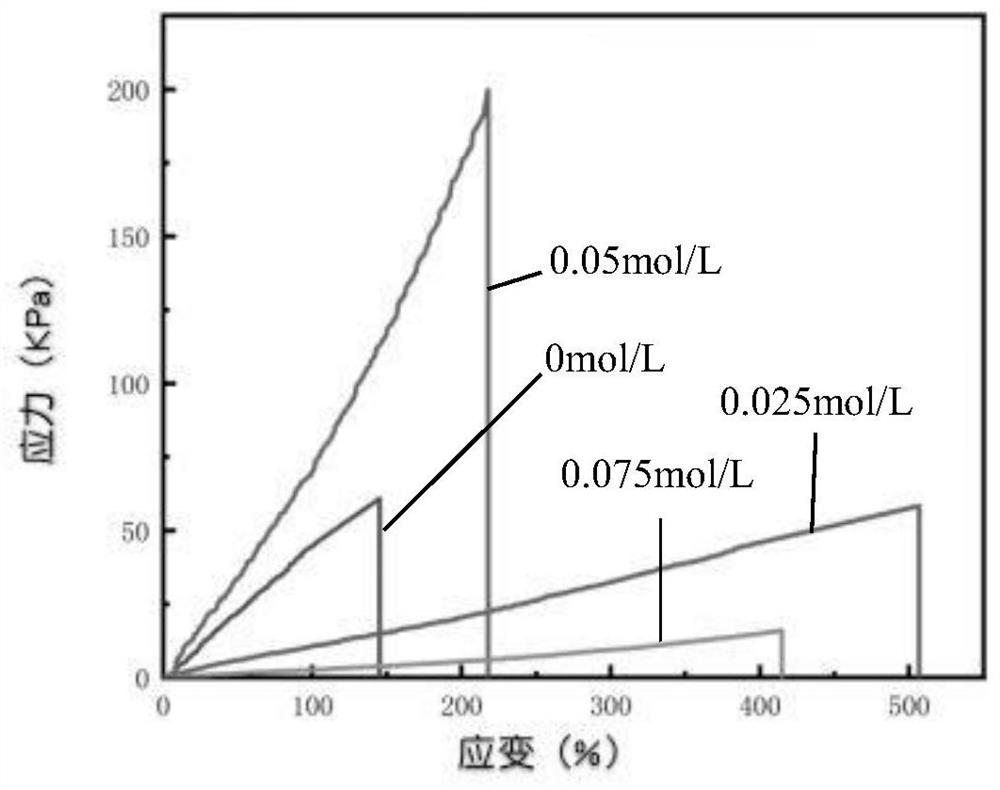

[0073] Example 3 Investigate the influence of different concentrations of metal ions on the gelation and properties of hydrogels

[0074] The specific experimental process is basically the same as the preparation method of sample D1, the difference is that different types of metal ions with different concentrations are changed. The specific conditions are shown in Table 1. The obtained conductive hydrogel corresponding to the metal coordination is recorded as the sample N1-N4 (nickel ions), Z1-Z4 (zinc ions).

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com