Method for detecting terbutaline sulfate injection and related substances

A technology for detecting terbutaline sulfate and a detection method, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of not providing terbutaline sulfate injection and detection methods for degraded impurities, and achieve good durability and improved The effect of high control and impurity separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

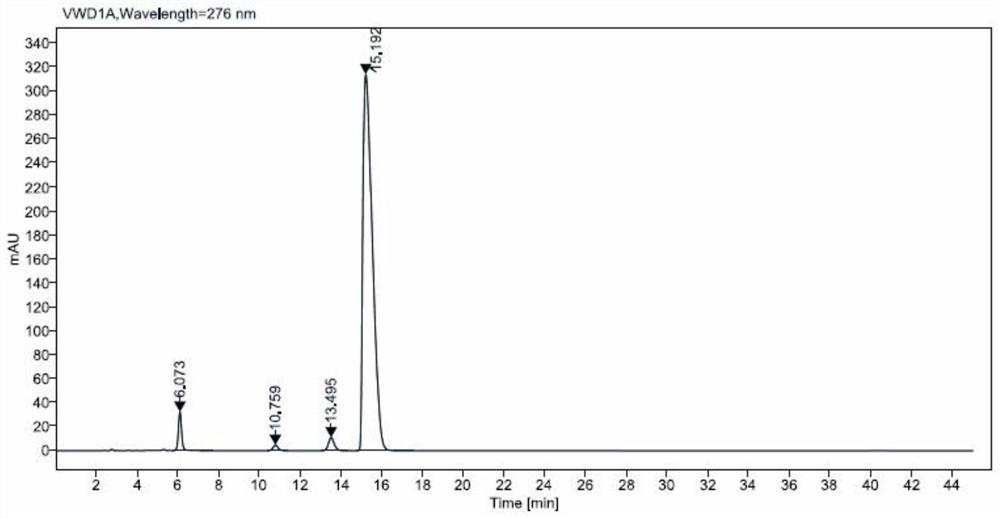

[0066] System suitability test for the detection of terbutaline sulfate injection and related substances by high performance liquid chromatography, the test conditions are:

[0067] Chromatographic column: Agilent ZORBAX Eclipse Plμs-C18 (250×4.6mm, 5μm);

[0068] Mobile phase: take 4.08g of sodium hexanesulfonate, 1.41g of sodium sulfate and 3.15g of ammonium formate, put it in a 1000mL measuring flask, add about 960mL of water, add formic acid (about 8mL) to adjust the pH value to 3.0, dilute to the mark with water, shake It is mobile phase A until it is completely dissolved. Take 800 mL of mobile phase A and 200 mL of methanol (mobile phase B), and mix well;

[0069] Detection wavelength: 276nm;

[0070] Column temperature: 30℃;

[0071] Flow rate: 1.0mL / min;

[0072] Injection volume: 50 μL;

[0073] System suitability solution: take appropriate amount of terbutaline sulfate standard and impurity B, C, F reference substances, add mobile phase to dissolve and quantitat...

Embodiment 2

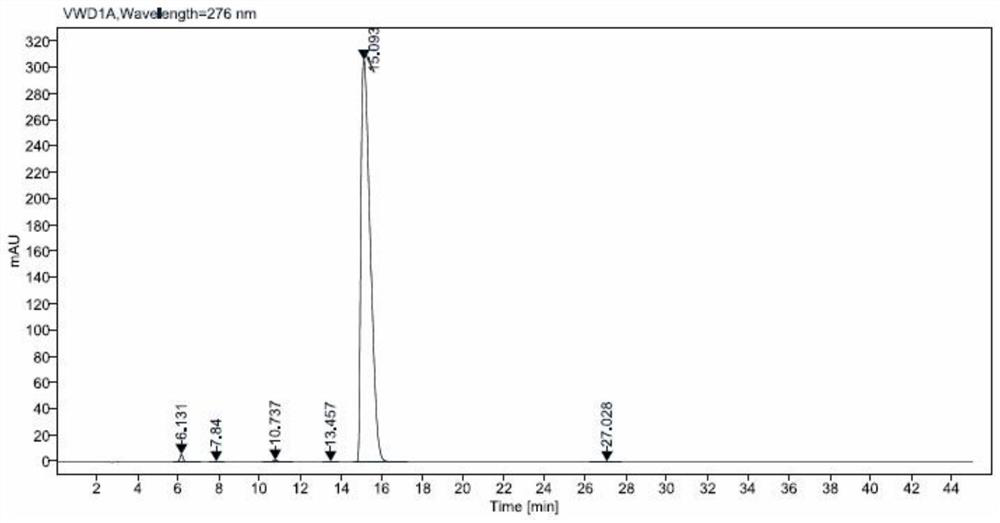

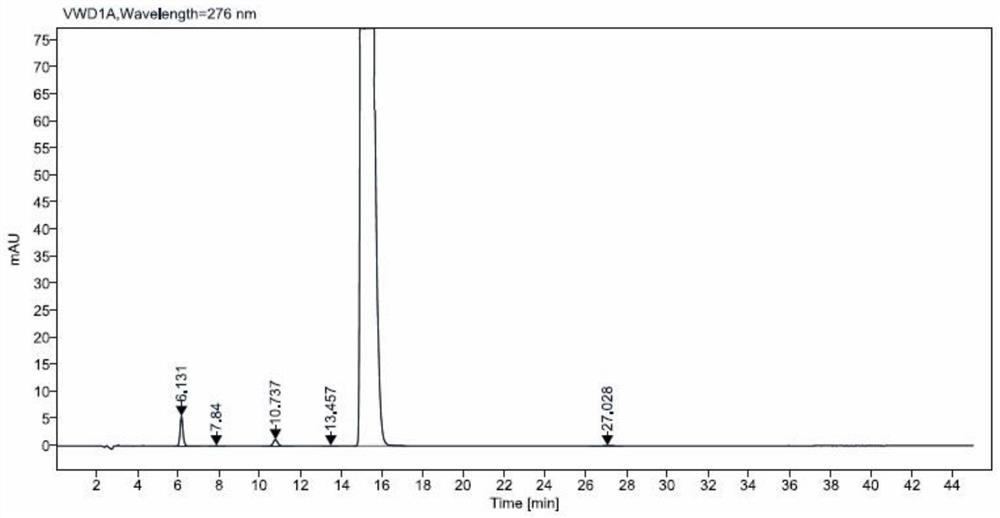

[0079] The detection conditions of Terbutaline Sulfate Injection and related substances are as follows:

[0080] Chromatographic column: Agilent ZORBAX Eclipse Plμs-C18 (250×4.6mm, 5μm);

[0081] Mobile phase: take 4.08g of sodium hexanesulfonate, 1.41g of sodium sulfate and 3.15g of ammonium formate, put it in a 1000mL measuring flask, add about 960mL of water, add formic acid (about 8mL) to adjust the pH value to 3.0, dilute to the mark with water, shake It is mobile phase A until it is completely dissolved. Take 800 mL of mobile phase A and 200 mL of methanol (mobile phase B), and mix well;

[0082] Detection wavelength: 276nm;

[0083] Column temperature: 30℃;

[0084] Flow rate: 1.0mL / min;

[0085] Injection volume: 50 μL;

[0086] Test solution: Take 5 tubes of homemade Terbutaline Sulfate Injection, mix well, take an appropriate amount, and use it as the test solution (0.5mg / mL);

[0087] Wherein, the preparation method of self-made terbutaline sulfate injection: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com