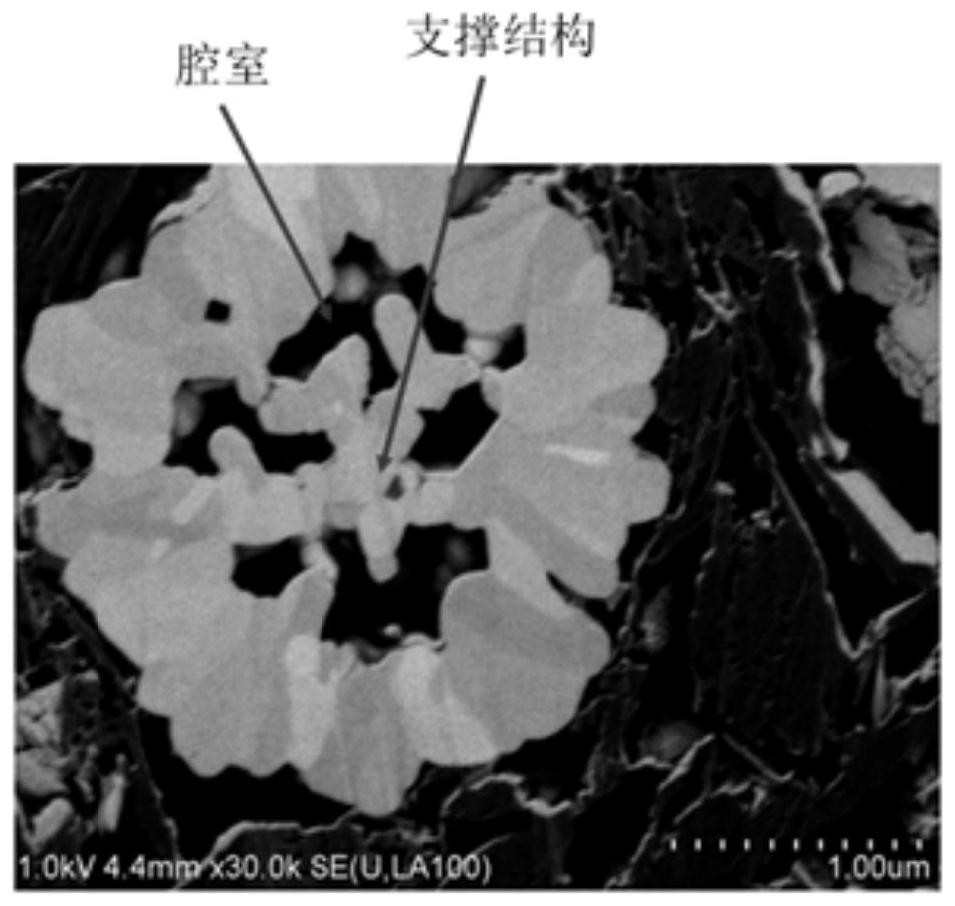

Positive electrode material with multi-cavity structure, preparation method of positive electrode material and lithium ion battery

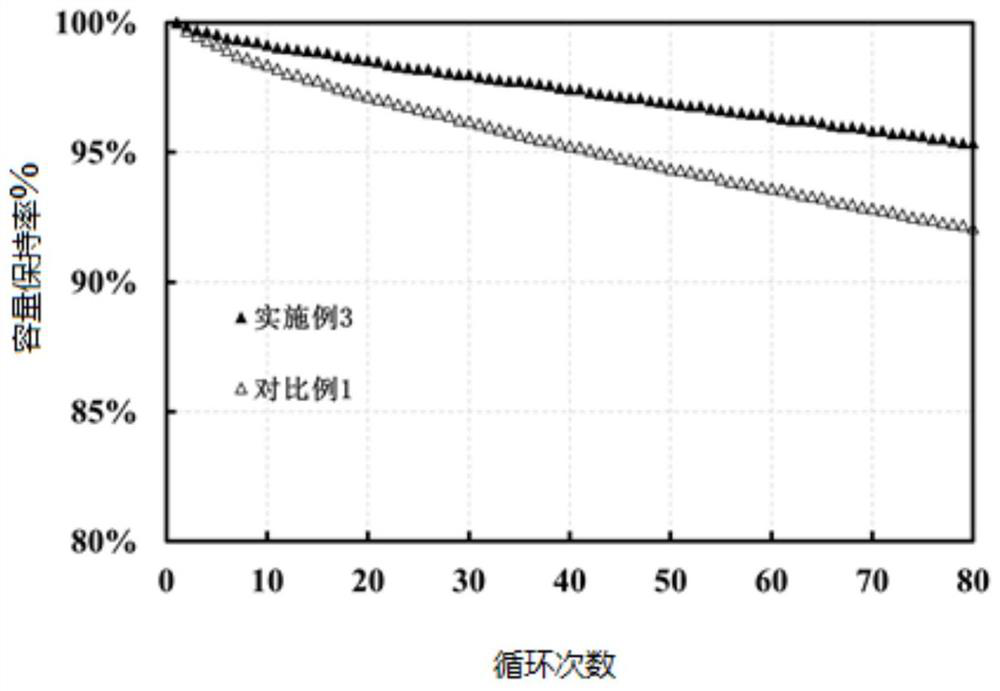

A positive electrode material and multi-chamber technology, applied in the direction of positive electrodes, structural parts, battery electrodes, etc., can solve the problems of reduced impedance of positive electrode materials, low cycle life of positive electrode materials, and poor strength, so as to improve cycle performance and suppress microcracks , enhance the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A second aspect of the present invention provides a method for preparing the aforementioned positive electrode material, wherein the preparation method includes:

[0048] (1) Under the protection of an inert gas, an aqueous solution containing Ni, Co, and Mn soluble salts, a complexing agent and a precipitating agent are mixed to carry out a co-precipitation reaction to obtain Ni 1-x-y Co x Mn y (OH) 2 hydroxide precursor; the Ni 1-x-y Co x Mn y (OH) 2 The core of the hydroxide precursor is ≤2.0μm;

[0049] (2) The Ni 1-x-y Co x Mn y (OH) 2 The hydroxide precursor, the lithium source and the optional compound containing the M element are mixed and then sintered, and the sintered material is crushed and sieved to obtain the positive electrode material Li 1+a Ni 1-x-y Co x Mn y O 2 or Li 1+a Ni 1-x-y-z Co x Mn y M z O 2 .

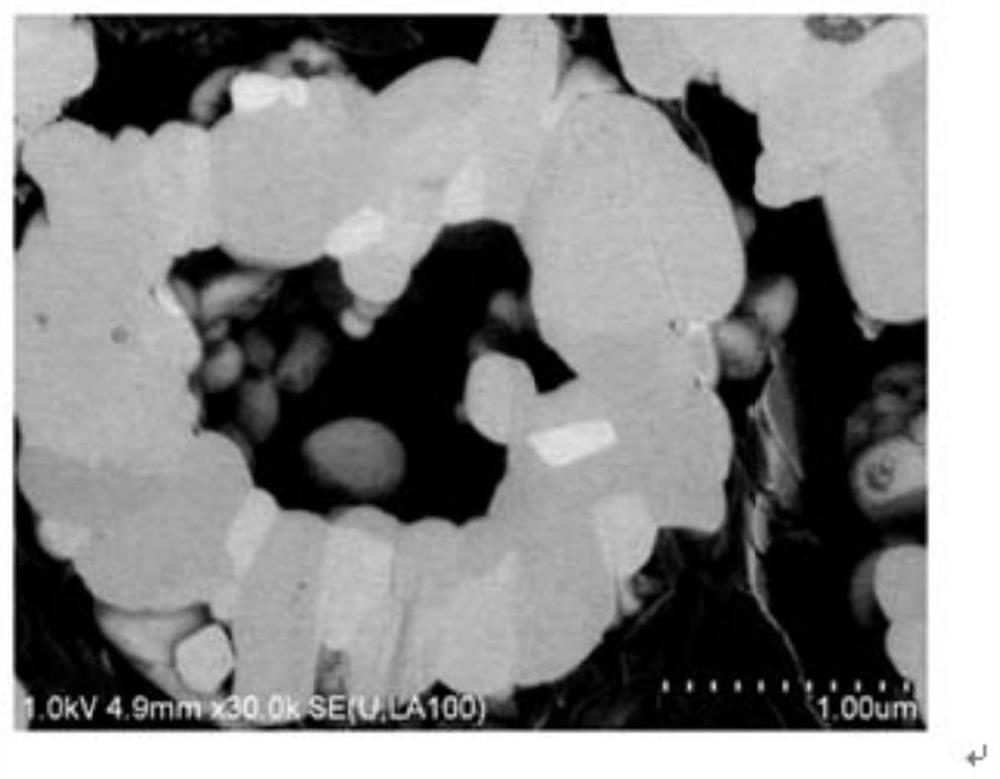

[0050] The inventor of the present invention found that: in the process of the preparation method of the precursor, by adjusting...

Embodiment approach

[0066] According to the present invention, the lithium source is selected from one or more of lithium carbonate, lithium hydroxide and lithium nitrate. According to a particularly preferred embodiment of the present invention, the preparation method of the positive electrode material includes:

[0067] (1) Prepare an aqueous solution of Ni, Co, and Mn soluble salts with a certain concentration, and then add it, precipitating agent and complexing agent into the stirring reaction kettle respectively, maintaining a certain reaction temperature, and under the protection of inert gas, Ni is obtained by co-precipitation 1-x-y Co x Mn y (OH) 2 hydroxide precursor;

[0068] (2) uniformly mix the above-obtained hydroxide precursor with a lithium source and a compound containing M element, place it in an atmosphere furnace for sintering, and crush and sieve the sintered material to obtain a positive electrode material Li 1+a Ni 1-x-y-z Co x Mn y M z O 2 .

[0069] A third asp...

Embodiment 1

[0085] This example is to illustrate the positive electrode material prepared by the method of the present invention.

[0086] (1) the molar ratio of preparing nickel sulfate, cobalt sulfate and manganese sulfate is 0.33:0.33:0.34 1.5mol / L mixed solution, this mixed solution, complexing agent ammonia solution, precipitating agent sodium hydroxide solution are passed into reaction In the kettle, nitrogen was introduced as a protective gas, the ammonia concentration was controlled at 10g / L, the pH was controlled at 12.0, and the rotational speed was controlled at 70rpm. After maintaining this condition for 3h, the core growth was completed. The core was 0.9μm, and the internal crystal structure of the core was Small size and dense structure; then the ammonia content was increased to 16g / L, the pH was decreased to 11.5, and the rotational speed was decreased to 55rpm, and the conditions were maintained until particle D 50 After growing to 4.0 μm, the reaction was stopped; the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com