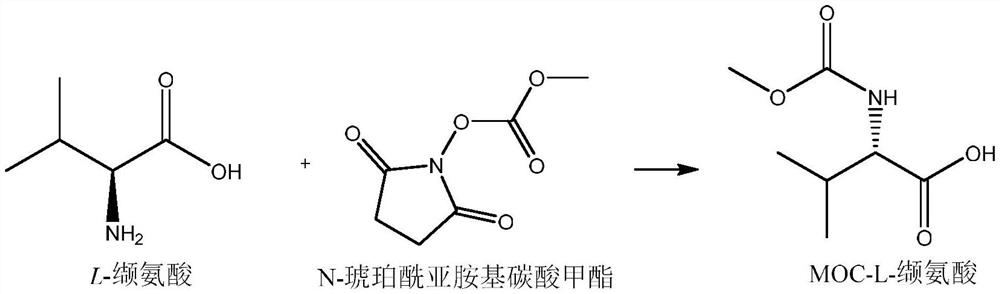

Synthesis process of MOC-L-valine

A technology of MOC-L-, synthesis process, applied in the field of MOC-L-valine synthesis process, can solve the problem of irritating odor and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

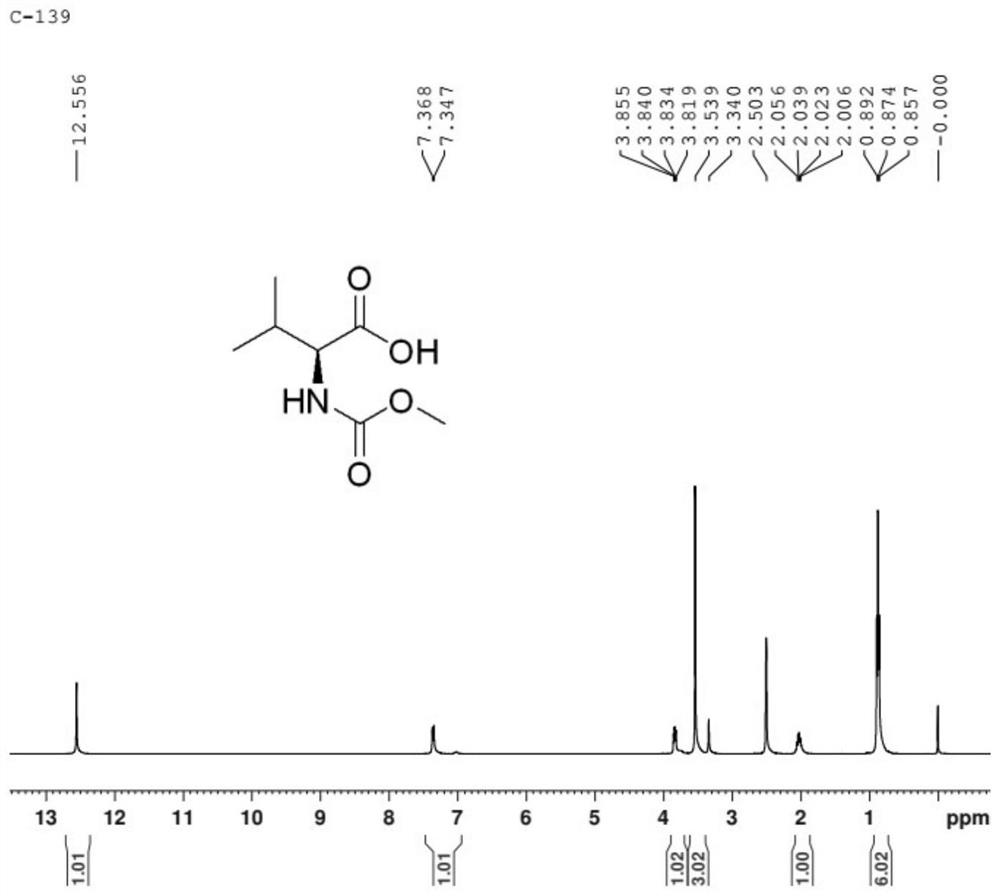

Image

Examples

Embodiment 1

[0035] Put 110g of water and 40g of liquid caustic soda with a mass fraction of 32% into a 500ml four-necked bottle, turn on stirring, control the temperature of the kettle to be no higher than 20°C, put in 35g of L-valine, and stir until all the solids are dissolved. The internal temperature of the reaction kettle was controlled to be 5-20°C, and 56.9 g of N-succinimidyl methyl carbonate was added in batches at the same time. After the feeding was completed, the internal temperature of the reaction kettle was controlled to be 50-60°C, and the temperature was maintained and stirred for 2-3 hours. Sampling in the control, requires L-valine ≤ 2%. Add 160 g of toluene to the reaction solution, cool down to below 15°C, dropwise add sulfuric acid to adjust pH=2~3, a large amount of solid salt does not dissolve, be warming up to 23~28°C and stir the salt to dissolve completely, separate the water layer to obtain the organic layer. The organic layer was washed three times with 15% br...

Embodiment 2

[0037] Put 110g of water and 53g of sodium carbonate into a 500ml four-necked bottle, turn on stirring, control the temperature of the kettle to be no higher than 20°C, put in 35g of L-valine, and stir until all the solids are dissolved. The internal temperature of the reaction kettle was controlled to be 5-20°C, and 56.9 g of N-succinimidyl methyl carbonate was added in batches at the same time. After the feeding was completed, the internal temperature of the reaction kettle was controlled to be 10-20°C, and the temperature was kept and stirred for 2-3 hours. Sampling in the control, requires L-valine ≤ 2%. Add 160 g of ethyl acetate to the reaction solution, cool down to below 15°C, dropwise add sulfuric acid to adjust pH=2~3, a large amount of solid salt does not dissolve, be warming up to 23~28°C and stir the salt to dissolve completely, separate the water layer to obtain the organic layer . The organic layer was washed with 15% brine, and the internal temperature was con...

Embodiment 3

[0039]Put water 110g and sodium bicarbonate 84g into a 500ml four-neck flask, turn on stirring, control the temperature of the kettle to be no higher than 20°C, put in 35g of L-valine, and stir until all the solids are dissolved. The internal temperature of the reaction kettle was controlled to be 5-20°C, and 56.9 g of N-succinimidyl methyl carbonate was added in batches at the same time. After the feeding was completed, the internal temperature of the reaction kettle was controlled to be 10-20°C, and the temperature was kept and stirred for 2-3 hours. Sampling in the control, requires L-valine ≤ 2%. Add 160 g of tetrahydrofuran to the reaction solution, cool down to below 15°C, dropwise add sulfuric acid to adjust pH=2~3, a large amount of solid salt does not dissolve, heat up to 23~28°C and stir the salt to dissolve completely, separate the water layer to obtain the organic layer. The organic layer was washed with 15% brine, and the internal temperature was controlled not to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com