Histamine double-iodized salt and preparation method thereof, perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of low efficiency of flexible perovskite solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

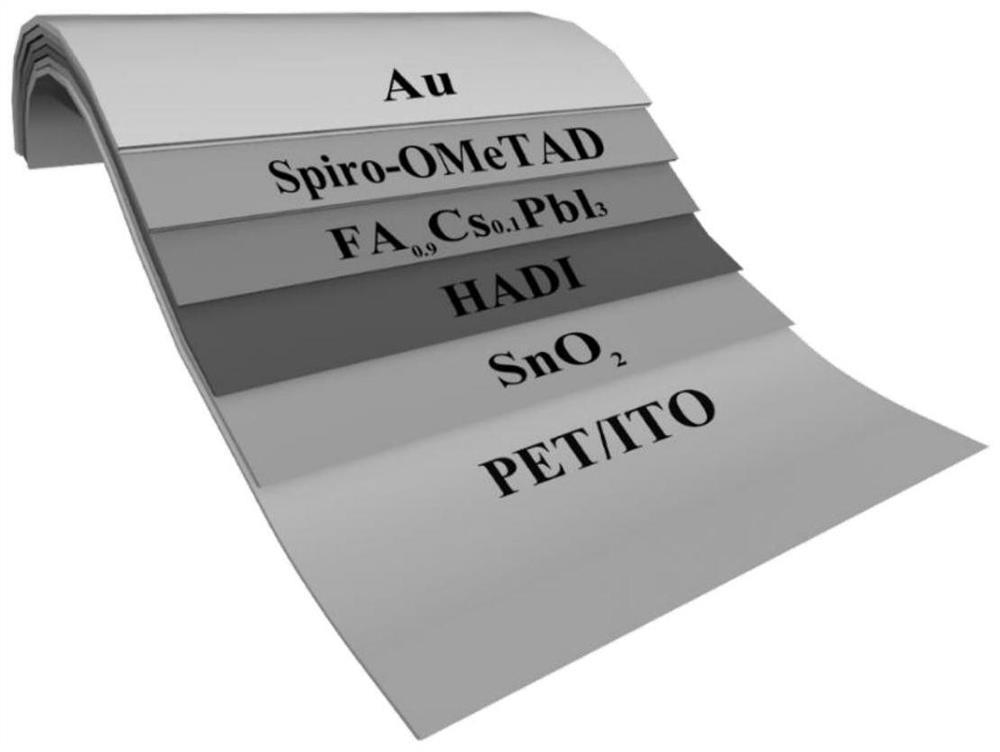

[0048] The embodiment of the present invention also discloses a histamine double iodide salt and a preparation method thereof, as well as a perovskite battery and a preparation method, comprising the following steps:

[0049] Step 1, magnetron sputtering a layer of ITO or FTO on the front of the PET substrate;

[0050] ITO or FTO with a thickness of 160 nm was deposited on the front side of the PET substrate at low temperature by magnetron sputtering technology. The PET / ITO (FTO) substrate was blown with compressed air and treated with UV ozone for 8 min.

[0051] Step 2, Preparation of SnO 2 Electron transport layer precursor solution and HADI aqueous solution;

[0052] SnO 2 The preparation method of the electron transport layer precursor solution is: SnO 2 The colloidal nanoparticles are dissolved in deionized water (V / V=1:6), and stirred for 6-12 hours for use; the preparation method of the HADI aqueous solution is: Dissolve 1-6 mg of HADI solid powder in 1 mL of deion...

Embodiment 1

[0067] First, magnetron sputtering a layer of ITO on the front side of the PET substrate: ITO with a thickness of 160 nm is deposited on the front side of the PET substrate at a low temperature by the magnetron sputtering technology. The PET / ITO substrate was blown with compressed air and treated with UV ozone for 8 min.

[0068] Second, the preparation of SnO 2 Electron transport layer precursor solution and HADI aqueous solution: SnO 2 The preparation method of the electron transport layer precursor solution is: SnO 2 The colloidal nanoparticles were dissolved in deionized water (V / V=1:6) and stirred for 6 hours for later use; the preparation method of the HADI aqueous solution was as follows: 2 mg of HADI solid powder was dissolved in 1 mL of deionized water, stirred for 2 h, and filtered for later use.

[0069] Third, preparation of SnO 2 Electron transport layer: SnO prepared in step 2 2The colloidal nanoparticle solution was spin-coated on the surface of the PET / ITO ...

Embodiment 2

[0102] In this embodiment, instead of using PET / ITO as the conductive layer, FTO is used, and the FTO substrate is cleaned in an ultrasonic cleaning machine with glass cleaner and ultrapure water (glass cleaner: ultrapure water=1:100) 30min, then replace the ultrapure water every 30min, and repeat this step 3 times. The cleaned FTO substrate was dried by compressed air, then treated with ultraviolet ozone for 15 min, and the prepared SnO was spin-coated on the FTO substrate 2 Nano colloid solution, spin coating speed is 3000rpm, spin coating time is 40s, and then annealing treatment, annealing temperature is 150 ℃, annealing time is 20min. SnO was treated with UV ozone prior to spin-coating the formulated HADI aqueous solution 2 / FTO substrate 10min. Spin-coat 2 mg / mL HADI aqueous solution on FTO / SnO 2 On the surface of the substrate, the spin coating speed is 3000 rpm, the spin coating time is 30 s, and then the annealing treatment is performed, the annealing temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com