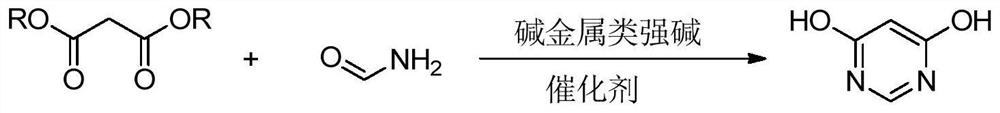

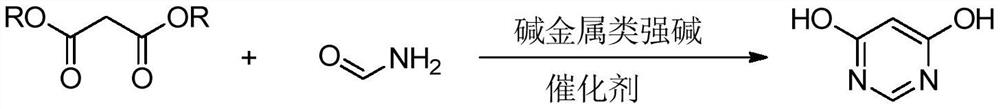

Preparation method of 4, 6-dihydroxypyrimidine

A technology of dihydroxypyrimidine and malonate, applied in the direction of organic chemistry, can solve problems such as shortages, achieve the effects of reducing dosage, exerting economic benefits, and improving reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, 4,6-dihydroxypyrimidine is prepared by the following method, which specifically includes the following steps:

[0039] Set up a four-necked flask reaction device equipped with a constant pressure dropping funnel, stirring paddle, thermometer and reflux condenser, weigh 81.03g (0.450mol) (content 30%) of sodium methoxide / methanol solution, 0.43g (0.0023mol) ( content 97%) tetramethylammonium hydroxide pentahydrate, stir evenly, heat up to 60 ° C, start to dropwise add 30.03g (0.225mol) (content 99%) dimethyl malonate and 25.57g (0.562mol) (content 99%) formamide mixture, the dropwise addition time is 45min. After the dropwise addition, the reaction was incubated at 60 °C for 3 h. Subsequently, methanol was recovered by distillation to dryness. After the residual solid was dissolved in water, it was acidified to pH 2.53 with 30% hydrochloric acid at 25°C, filtered, washed with water, and dried to obtain 24.06 g of 4,6-dihydroxypyrimidine with a conten...

Embodiment 2

[0041] In this embodiment, 4,6-dihydroxypyrimidine is prepared by the following method, which specifically includes the following steps:

[0042]Set up a four-necked flask reaction device equipped with a constant pressure dropping funnel, stirring paddle, thermometer and reflux condenser, weigh 81.03g (0.450mol) (content 30%) of sodium methoxide / methanol solution, 0.24g (0.0013mol) ( content 97%) tetramethylammonium hydroxide pentahydrate, stir evenly, heat up to 65 ℃, start to dropwise add 30.03g (0.225mol) (content 99%) dimethyl malonate and 25.57g (0.562mol) (content 99%) formamide mixture, the dropwise addition time is 1h. After the dropwise addition, the reaction was incubated at 65°C for 2h. Subsequently, methanol was recovered by distillation to dryness. After the residual solid was dissolved in water, it was acidified to pH 2.75 with 30% hydrochloric acid at 23°C, filtered, washed with water, and dried to obtain 23.88 g of 4,6-dihydroxypyrimidine with a content of 98....

Embodiment 3

[0044] In this embodiment, 4,6-dihydroxypyrimidine is prepared by the following method, which specifically includes the following steps:

[0045] Set up a four-necked flask reaction device equipped with a constant pressure dropping funnel, stirring paddle, thermometer and reflux condenser, and weigh 60.77g (0.450mol) (content 40%) sodium methoxide / methanol solution, 0.64g (0.0034mol) ( content 97%) tetramethylammonium hydroxide pentahydrate, stir evenly, heat up to 65 ℃, start to dropwise add 30.03g (0.225mol) (content 99%) dimethyl malonate and 28.66g (0.630mol) (content 99%) formamide mixture, the dropwise addition time is 1h. After the dropwise addition, the reaction was incubated at 65°C for 2h. Subsequently, methanol was recovered by distillation to dryness. After the residual solid was dissolved in water, it was acidified to pH 2.46 with 30% hydrochloric acid at 25°C, filtered, washed with water, and dried to obtain 24.16 g of 4,6-dihydroxypyrimidine with a content of 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com