Magnesium-based half Heusler alloy material and preparation method thereof

An alloy material, magnesium-based semi-technology, applied in the field of magnesium-based semi-Heusler alloy materials and their preparation, can solve the problems related to performance and data of undisclosed magnesium-based semi-Heusler alloy materials, and achieve abundant reserves and production Low cost and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The raw materials are stoichiometrically compared to Mg 0.5 Ti 0.5 After NiSb was calculated and weighed, it was fully mixed and placed in a tantalum tube protected by argon gas and sealed. The material was obtained by reacting at a high temperature of 1000 °C for 24 hours, and then the material was pulverized by mechanical ball milling to obtain material powder, and then the spark plasma sintering method was used at 920 °C. The final sample was obtained by sintering at 60 MPa for 10 min.

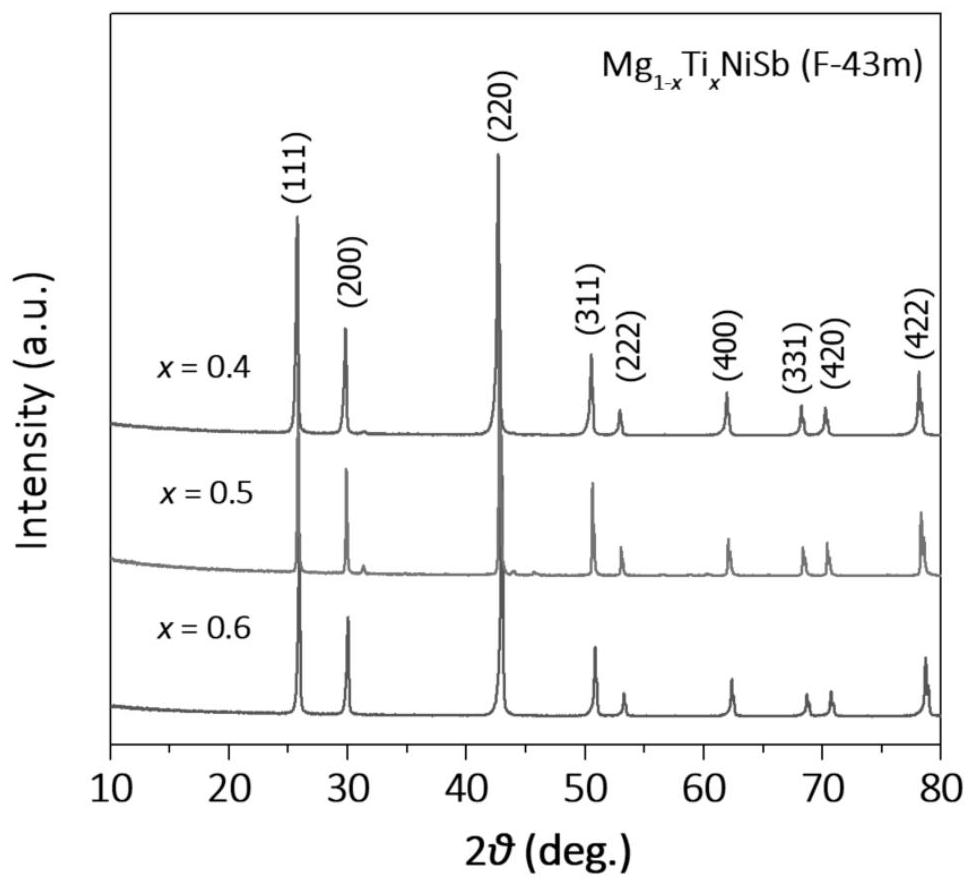

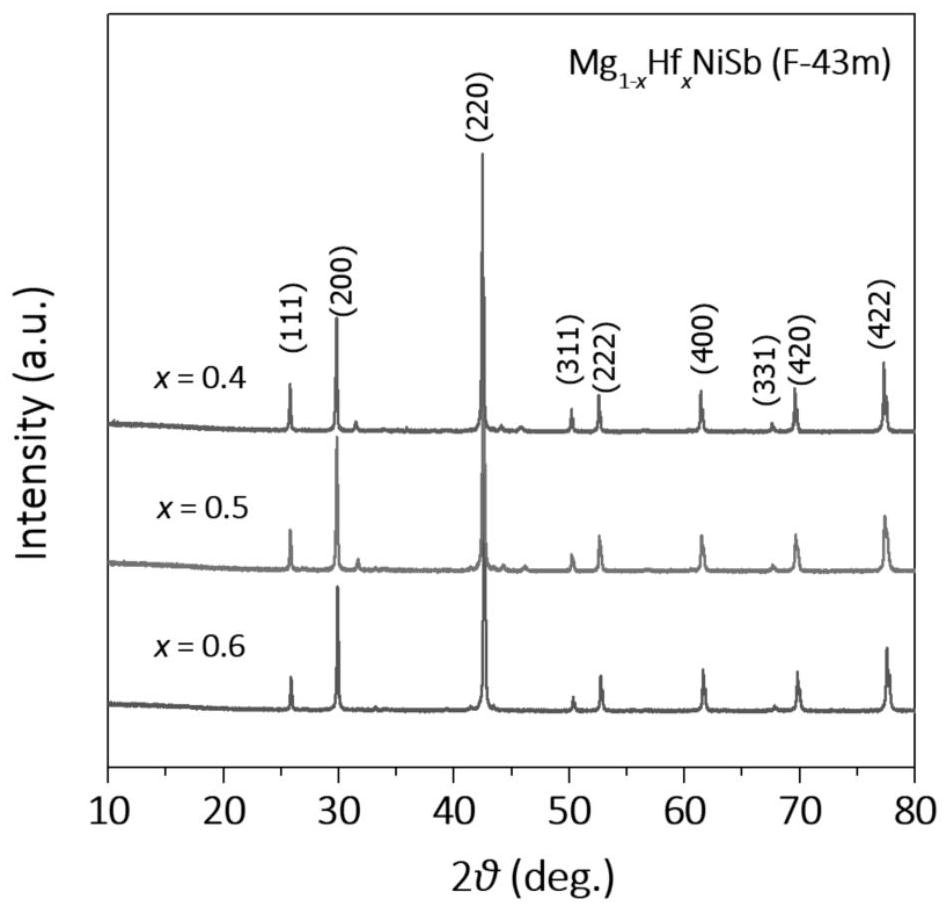

[0035] The phase analysis of the samples prepared in this example was carried out by using the Netherlands PANalytical (Aries DY866) X-ray polycrystalline diffractometer (XRD). figure 1 shown, and confirmed to be a half-Heusler alloy structure, namely a cubic structure (F4_3m), with a space group number of 216.

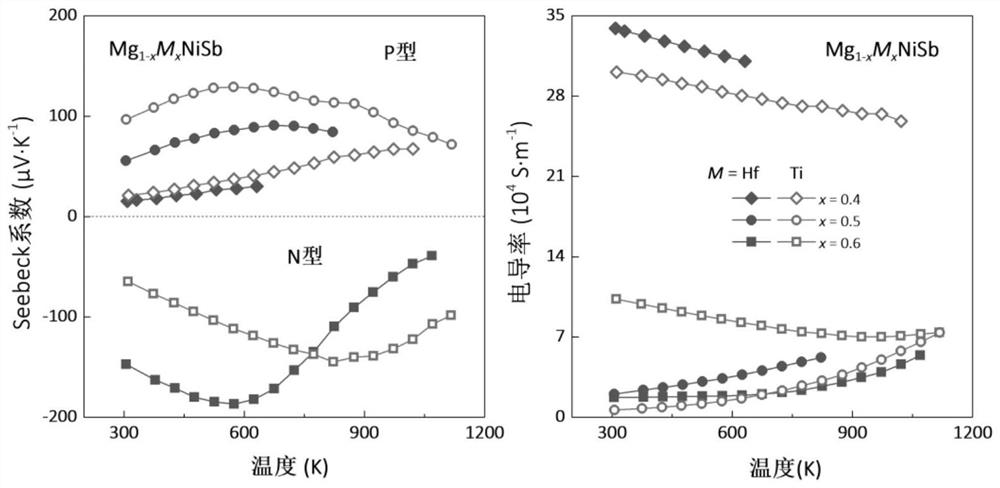

[0036] The thermoelectric coefficient S=97μV / K of the material at room temperature was measured by Linses LSR-3 equipment, indicating that the carrier type of the material...

Embodiment 2

[0039] The raw materials are stoichiometrically compared to Mg 0.4 Ti 0.6 After NiSb is calculated and weighed, it is fully mixed and placed in a tantalum tube protected by argon gas and sealed. The material is obtained by reacting at a high temperature of 1000 ° C for 24 hours, and then the material is pulverized by the mechanical ball milling method to obtain the material powder, and then the spark plasma sintering method is used at 900 ° C. The final sample was obtained by sintering at 60 MPa for 10 min.

[0040] Phase analysis of the samples prepared in this example was carried out by XRD, such as figure 1 shown and confirmed to be a half-Heusler alloy structure, namely a cubic structure (F43m), with space group number 216.

[0041] The thermoelectric coefficient S=-65μV / K of the material at room temperature was measured by Linses LSR-3 equipment, indicating that the carrier type of the material is hole (N-type), and the electrical conductivity σ=10.3×10 4 The relations...

Embodiment 3

[0044] The raw materials are stoichiometrically compared to Mg 0.6 Ti 0.4 After NiSb is calculated and weighed, it is fully mixed and placed in a tantalum tube protected by argon gas and sealed. The material is obtained by reacting at a high temperature of 1000 ° C for 24 hours, and then the material is pulverized by the mechanical ball milling method to obtain the material powder, and then the spark plasma sintering method is used at 900 ° C. The final sample was obtained by sintering at 60MPa for 5min.

[0045] Phase analysis of the samples prepared in this example was carried out by XRD, such as figure 1 shown, and confirmed to be a half-Heusler alloy structure, namely a cubic structure (F4_3m), with a space group number of 216.

[0046] The thermoelectric potential coefficient S=21μV / K of the material at room temperature was measured by Linses LSR-3 equipment, indicating that the carrier type of the material is hole (P-type), and the conductivity σ=30×10 4 The relations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com