Working solution, preparation method thereof and application of working solution in production of hydrogen peroxide by anthraquinone method

A working fluid, hydrogen peroxide technology, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, etc., can solve the problem of increasing the production cost of hydrogen peroxide, working fluid Problems such as large workload and high price of tetrabutyl urea can improve hydrogenation efficiency, improve solubility, and increase density difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

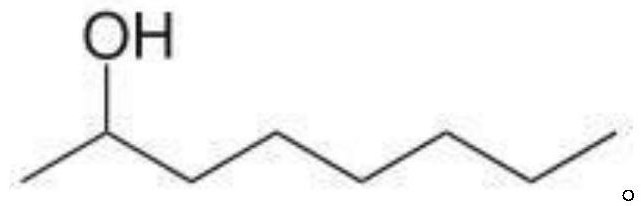

Image

Examples

Embodiment 1

[0056] Heavy aromatic hydrocarbon: trioctyl phosphate: 2-methylcyclohexyl acetate: 2-octanol=78:12:8:2 (volume ratio) is used as the working liquid solvent system. The heavy aromatics are composed of C10 aromatics (including tetramethylbenzene, meta-tetramethylbenzene, mesitylene, methylpropylbenzene, butylbenzene, diethylbenzene, methylindene and naphthalene, wherein the aromatic hydrocarbon mass fraction is greater than 99%, Purchased from Nanjing Covent Chemical Co., Ltd.), the flash point is 74°C, and the density is 0.8898g / cm 3 . Working carrier: The sum of the solubility of 2-ethylanthraquinone and tetrahydro-2-ethylanthraquinone is 177 g / L. The temperature of the hydrogenation reaction is 45℃, the reaction pressure is 0.25MPa, and the working fluid space velocity is 10h -1 , the volume flow ratio of working fluid and hydrogen is 1:6.67 (standard state). The oxidation reaction temperature was 50°C, and the reaction pressure was 0.2 MPa. The extraction reaction temper...

Embodiment 2

[0058] Using heavy aromatic hydrocarbons: trioctyl phosphate: 2-methylcyclohexyl acetate: 2-octanol=70:15:11:4 (volume ratio) as the working liquid solvent system, and others are the same as in Example 1. Working carrier: The solubility of 2-ethylanthraquinone and tetrahydro-2-ethylanthraquinone is 169 g / L. Working fluid airspeed is 11h -1 , the volume flow ratio of working fluid and hydrogen is 1:6.36 (standard state). The measured hydrogen efficiency is 9.65g / L, the density of the working solution is 0.907g / ml, the hydrogen peroxide content in the raffinate is 0.12g / L, and the total organic carbon content (TOC ) was 248ppm.

Embodiment 3

[0060] Using heavy aromatic hydrocarbons: trioctyl phosphate: 2-methylcyclohexyl acetate: 2-octanol=66:13:16:5 (volume ratio) as the working liquid solvent system. Others are the same as in Example 1. Working carrier: The solubility of 2-ethylanthraquinone and tetrahydro-2-ethylanthraquinone is 165g / L. Working fluid airspeed is 9h -1 , the volume flow ratio of working fluid and hydrogen is 1:6.21 (standard state). The measured hydrogen efficiency was 9.43g / L, the density of the working solution was 0.908g / ml when measured at 45°C, the hydrogen peroxide content in the raffinate was 0.1g / L, and the amount of hydrogen peroxide in the extract (the crude product of hydrogen peroxide) was The total organic carbon content (TOC) was 252 ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com