System and method for replacing fuel with biomass in cement kiln

A biomass fuel and alternative fuel technology, applied in waste fuel, cement production, combustion methods, etc., can solve problems such as the inability to achieve large-scale application in large quantities, reduce energy consumption for crushing, increase calorific value significantly, and save energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

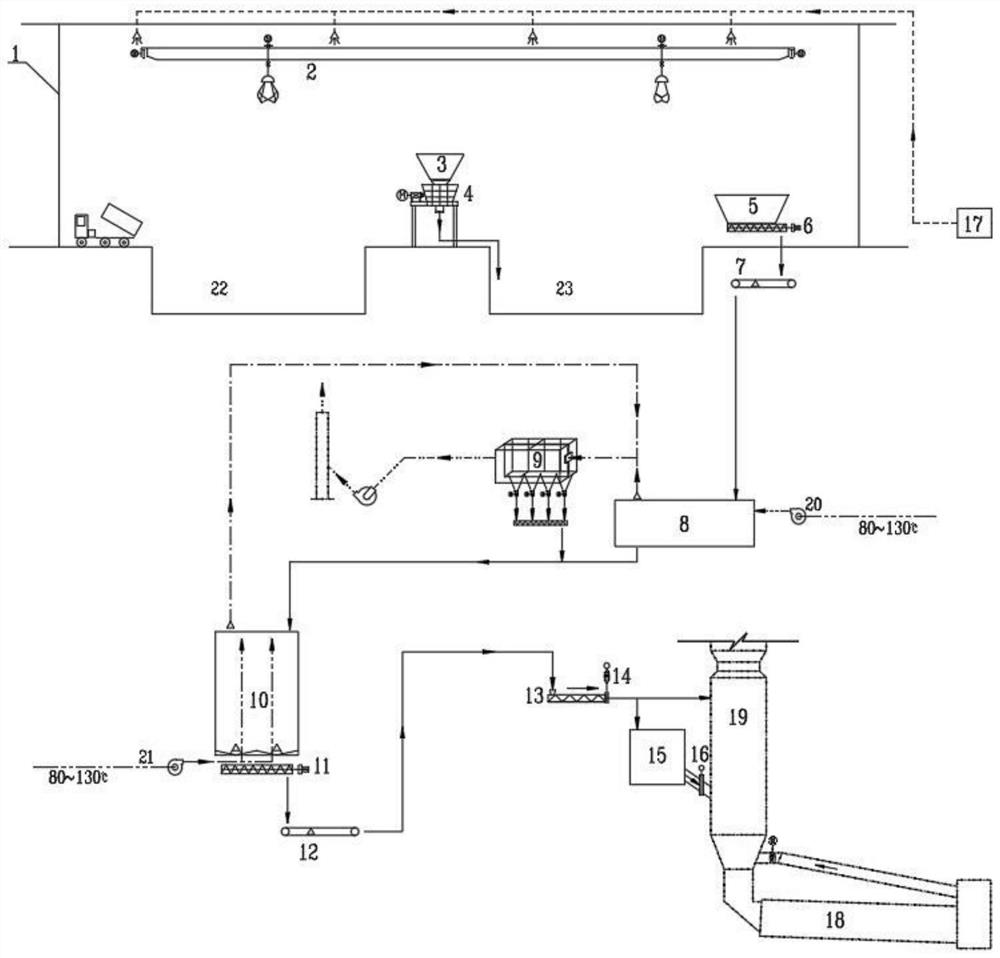

[0038] refer to figure 1 As shown in the figure, a system for replacing fuel with biomass in a cement kiln includes a combined fuel storage workshop 1, a second conveying quantitative component, a primary drying device 8, a dust collector 9, a secondary drying and homogenizing bin 10, a first Three conveying quantitative components, the fourth conveying component and the pre-burning furnace 15. The rotary kiln 18 and the calcining furnace 19 are the original cement kiln system, and the calcining furnace 19 is connected to the end of the rotary kiln 18.

[0039] The fuel combined storage workshop 1 is provided with an intelligent grab crane 2 , a first feeding bin 3 , a crusher 4 , a spray dust removal device 17 , a large particle size biomass fuel pit 22 and a small particle size biomass fuel pit 23 . The second conveying quantitative assembly includes a second feeding bin 5, a second screw conveyor 6 and a second quantitative feeder 7. The third conveying and quantitative a...

Embodiment 2

[0050] A kind of method that a cement kiln utilizes biomass to replace fuel, adopts the system that above-mentioned cement kiln utilizes biomass to replace fuel, comprises the steps:

[0051] Step 1, the biomass fuel is sent into the fuel joint storage workshop 1, and is classified according to the particle size of the entrance is greater than or less than 100mm, and enters the large particle size biomass fuel pit 22 or the small particle size biomass fuel pit 23 respectively. The types of biomass fuels include one or more types, the particle size of which is less than 500mm, and the moisture content is less than or equal to 80%.

[0052] In step 2, the large particle size biomass fuel is sent into the first feeding bin 3 through the coarse material grab in the intelligent grab crane 2, and is crushed to a particle size smaller than 100 mm by the crusher 4 below, and then enters the small particle size biomass. The fuel pit 23 is stored.

[0053] Step 3., the small particle s...

Embodiment 3

[0063] A method for replacing fuel with biomass in a cement kiln, comprising the following steps:

[0064] In step ①, straw with a particle size of 120 mm and a moisture content of 50% is sent into the large particle size biomass fuel pit 22 of the combined fuel storage workshop 1. In step (2), the straw is crushed to a particle size of 50 mm by the crusher 4 and enters the small particle size biomass fuel pit 23. In step ③, the waste heat flue gas from the kiln head is used as a heat source, and the inlet air temperature of the flue gas is set to 120°C, and the moisture content of the straw after drying is reduced from 50% to 25%. In step ④, the mixed waste heat flue gas from the kiln head and the kiln tail of the cement kiln is used as the heat source, and the inlet air temperature of the flue gas is set to 100 °C, and the moisture content of the straw is reduced from 25% to 18% after the secondary drying. In step ⑤, the heat replacement rate of the decomposition furnace is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com