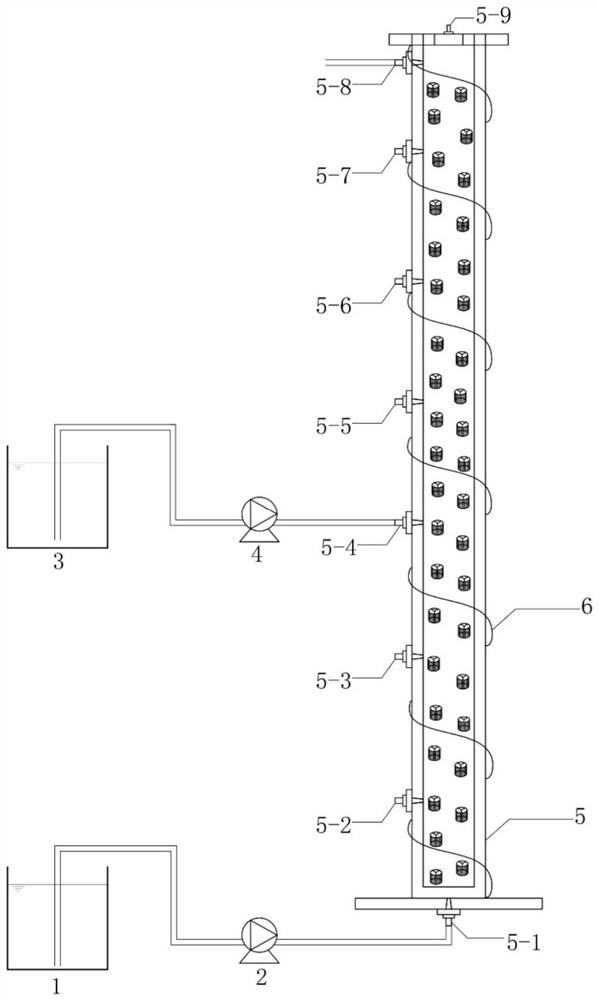

Anaerobic digestion and DAMO coupled biological filter column and method for treating carbon-nitrogen sewage

An anaerobic digestion and biological filtration technology, which is applied in anaerobic digestion treatment, sustainable biological treatment, chemical instruments and methods, etc., can solve the problems of high cost, easy to be affected by environmental conditions, difficult enrichment and cultivation, etc., to achieve Reduce emissions and achieve low-consumption nitrogen and carbon removal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] In this example, an integrated biological filter column reactor with an effective volume of 2.4L was used, and a water outlet was set at 50% of the column height of the reactor, and then 300mL of flocculent sludge with a certain methane-producing capacity was inoculated into the reactor, and the MLVSS was 7g / L. Pump into SCOD=200mg / L, NH 4 + -N=30mg N / L synthetic wastewater A. The water temperature is 30 ℃, anaerobic and stable for 72 hours without entering water or water, so that the flocculation sludge and the filler in the lower section of the reactor are fully contacted to form a film.

[0074] Wastewater A includes SCOD, ammonia nitrogen, macroelements and trace elements. SCOD is added with 0.1709g / L anhydrous sodium acetate and 0.0623g / L glucose, and ammonia nitrogen is added with 0.1146g N / L ammonium chloride.

[0075] The major elements contain raw materials in the following mass ratios: CaCl 2 ·2H 2 O 0.06g / L, MgSO 4 ·4H 2 O 0.1g / L, K 2 HPO 4 ·3H 2 O...

Embodiment 2

[0093] In this example, an integrated biological filter column reactor with an effective volume of 2.4L was used, and a water outlet was set at 35% of the column height of the reactor, and then 350mL of flocculent sludge with a certain methane-producing capacity was inoculated into the reactor, and the MLVSS was 9g / L. Pump into SCOD=250mg / L, NH 4 + -N=20mg N / L synthetic wastewater A. The water temperature is 35°C, anaerobic and stable for 72 hours without water and water, so that the flocculent sludge and the lower filler of the reactor are fully contacted and filmed.

[0094] Wastewater A includes SCOD, ammonia nitrogen, macroelements and trace elements. SCOD is added with 0.2186g / L anhydrous sodium acetate and 0.0789g / L glucose, and ammonia nitrogen is added with 0.1228g N / L ammonium sulfate.

[0095] The major elements contain raw materials in the following mass ratios: CaCl 2 ·2H 2 O 0.06g / L, MgSO 4 ·4H 2 O 0.3g / L, K 2 HPO 4 ·3H 2 O 0.010g / L, KHCO 3 0.12g / L. ...

Embodiment 3

[0113] In this example, an integrated biological filter column reactor with an effective volume of 2.4L was used, and a water outlet was set at 45% of the column height of the reactor, and then 300mL of flocculent sludge with a certain methane-producing capacity was inoculated into the reactor, and the MLVSS was 7g / L. Pump into SCOD=150mg / L, NH 4 + -N=40mg N / L synthetic wastewater A. The water temperature is 28°C, anaerobic and stable for 96h without entering water or under water, so that the flocculent sludge and the filler in the lower section of the reactor are fully contacted to form a film.

[0114] Wastewater A includes SCOD, ammonia nitrogen, macroelements and trace elements. SCOD is added with 0.1282g / L anhydrous sodium acetate and 0.0467g / L glucose, and ammonia nitrogen is added with 0.1554g N / L ammonium chloride.

[0115] The major elements contain raw materials in the following mass ratios: CaCl 2 ·2H 2 O 0.07g / L, MgSO 4 ·4H 2 O 0.1g / L, K 2 HPO 4 ·3H 2 O ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com