Needle tip liquid, microneedle patch as well as preparation method and application of microneedle patch

A technology of microneedle sticking and needle tip, which is applied in the direction of pharmaceutical formulations, other medical devices, and medical preparations with non-active ingredients, etc. It can solve the problems of poor mechanical properties, poor mechanical properties of microneedles, and reduce the accumulation of antibacterial drugs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation and characterization of antibiotic-free ε-PLL / PVA soluble microneedle patches

[0051] 1. Preparation of the negative microneedle mold

[0052] Place the four-pyramid-shaped metal microneedle male mold (the height of the microneedles is 1200 μm, the width of the bottom is 300 μm, the distance between the tips of the needles is 800 μm, and the number of microneedles is 12×12) in absolute ethanol, ultrasonic for 20 minutes, and after repeated cleaning, the The male mold was placed at room temperature until the ethanol on its surface was completely evaporated. 9 mL of polydimethylsiloxane (PDMS) and 0.9 mL of curing agent (Dow Corning, USA) were mixed uniformly in a ratio of 10:1 (w / w) and stirred evenly, and the air bubbles were removed by vacuum for about 10 minutes. Pour the liquid PDMS containing the curing agent from the bubbles slowly into the male mold (6 g), then place it in a vacuum drying oven, connect the vacuum pump to degas for 45 minutes, until t...

Embodiment 2

[0060] Skin penetration performance of ε-PLL / PVA dissolvable microneedle patch without antibiotics

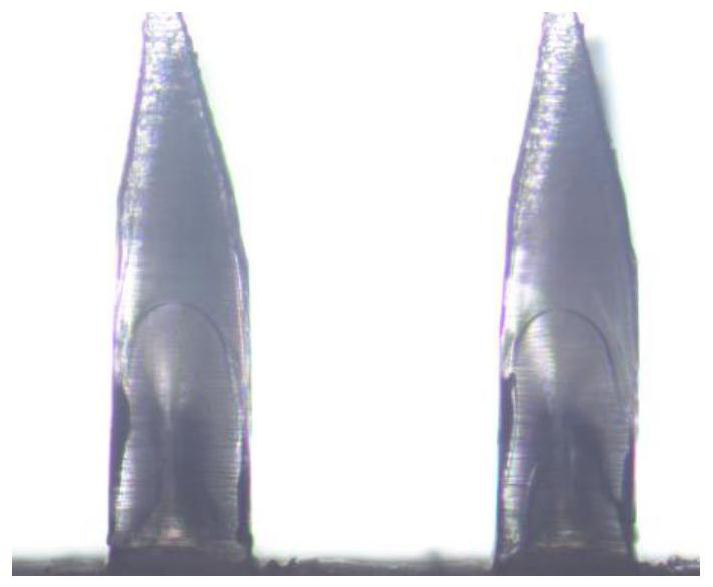

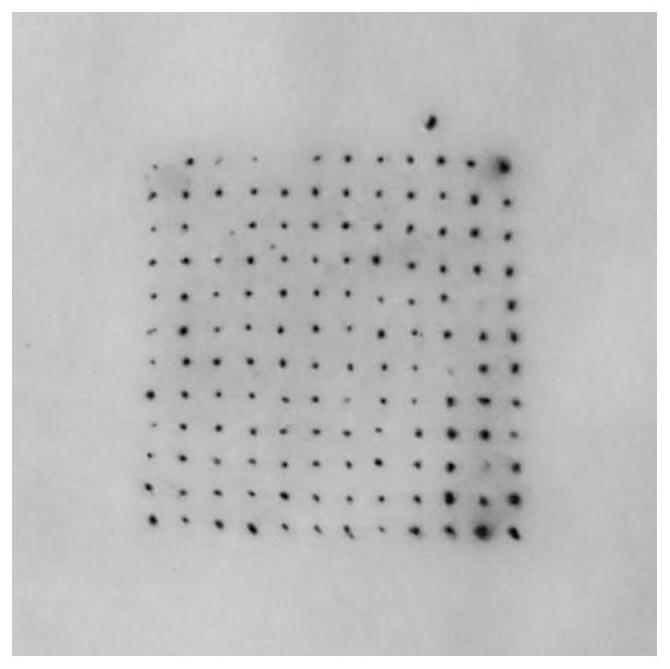

[0061] The mouse skin stratum corneum was flattened up on a flat plate, fixed with tacks, and after hair removal, the microneedle patch (ε-PLL:PVA-103=1:1) described in Example 1 was inserted into the skin, press 1 minutes, stick for 4 minutes, then remove the microneedles. Wash off the melted microneedle liquid with clean water, dip the skin surface with 4% (0.4g / 10mL) trypan blue solution for a period of time (about 2 minutes), remove the dye with clean water, dry it with tape to remove the background color , and observe the dyed pores on the skin surface and the removed microneedle tips. ( figure 2 )

[0062] figure 2 It shows that the soluble microneedle patch obtained by the prescription of ε-PLL:PVA-103=1:1 combines the hardness of ε-PLL and the toughness of macromolecular materials, and has good mechanical strength and puncture rate. reach more than 99%. image 3...

Embodiment 3

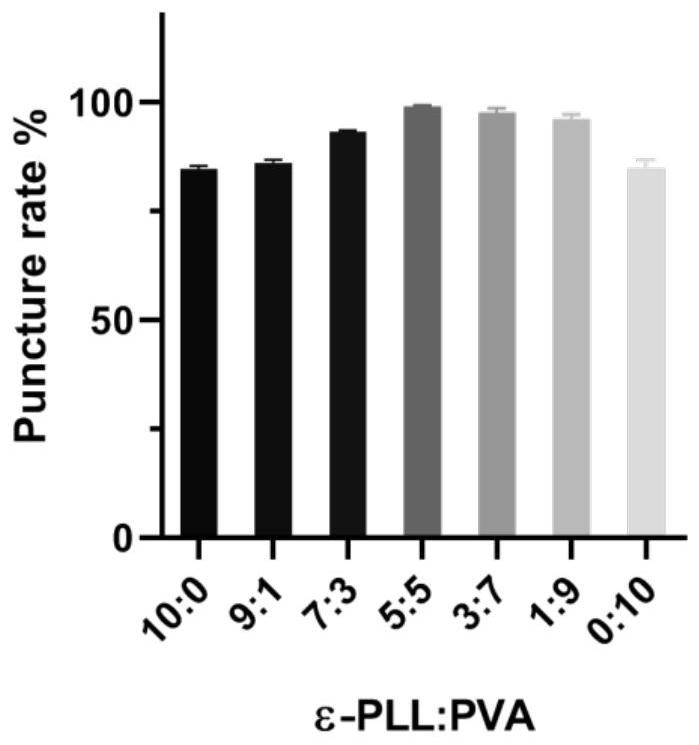

[0063] Example 3 Comparison of Microneedle Patches Constructed by Combinations of Different Excipients

[0064] ε--PLL was selected as the main needle tip matrix material, PVP, PVA or dextran (Dex 40) was used to improve the needle tip performance, and PVP K90 with an average molecular weight of 1300kDa was used as the base layer material to construct different soluble microneedle patches (for other parameters, please refer to Refer to the preparation method of Example 1). The experimental results see Figure 4 , when ε-PLL is matched with different excipients in different proportions, the quality of the prepared microneedles is different. When ε-PLL is used alone or with PVP k30 and Dex 40 alone, the prepared microneedles have uneven texture and high needle breakage rate, while when a certain proportion of PVA-103 is added to the prescription, the prepared microneedles break The needle rate is greatly reduced; the microneedles prepared by ε-PLL and PVA-103 are uniform in te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com