Evaporative crystallization process for calcium formate production

An evaporative crystallization and calcium formate technology, which is applied in solution crystallization, separation/purification of carboxylic acid compounds, preparation of carboxylate, etc., can solve the problems of heavy metals, arsenic, and calcium carbonate impurities that are easy to remain, lack of synthetic liquid purification steps, and difficult to guarantee Product quality and other issues, to achieve the effect of improving operational safety, pure white color, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to deepen the understanding of the present invention, the present invention will be described in further detail below with reference to the embodiments. The embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

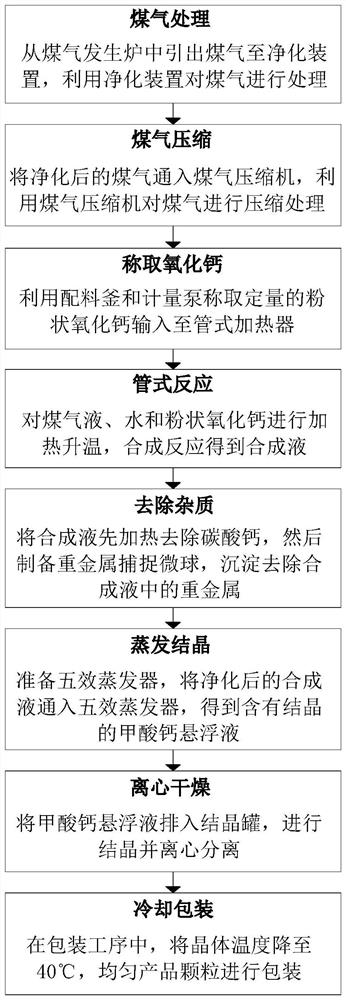

[0035] according to figure 1 As shown, the present embodiment proposes a kind of evaporative crystallization process for calcium formate production, comprising the following steps:

[0036] Step 1: Gas Treatment

[0037] The gas is drawn from the gas generator to the purification device, and the gas is treated by the purification device to increase the content of carbon monoxide and reduce the content of carbon dioxide and other impurities. The volume percentage of the product is reduced to below 2%;

[0038] Step 2: Gas Compression

[0039] Pass the purified gas into the gas compressor, and use the gas compressor to compress the gas to obtain gas liquid;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com