Medical porous Ti-Mn-Cu alloy and preparation method thereof

A ti-mn-cu, alloy technology, applied in the field of medical porous Ti-Mn-Cu alloy and its preparation, can solve the problems of lack of antibacterial properties of medical titanium alloy, high cost of medical titanium alloy, difficulty in preparation of titanium alloy, etc. Avoids toxicity issues, is low cost, eliminates the effect of "stress shielding" effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039]In a specific embodiment, the preparation method of the medical porous Ti-Mn-Cu alloy comprises:

[0040] a Weigh titanium powder, manganese powder and copper powder with a particle size below 300 mesh, mix them evenly, and dry to obtain a Ti-Mn-Cu mixed powder;

[0041] b. Mix the Ti-Mn-Cu mixed powder in step a with ammonium bicarbonate particles and a binder to obtain a mixture, and the mass ratio of the ammonium bicarbonate particles to the Ti-Mn-Cu mixed powder is 20-60:80-40; preferably The Ti-Mn-Cu mixed powder in step a is mixed with ammonium bicarbonate particles first, and then mixed with a binder to obtain a mixture;

[0042] c Pressing the mixture obtained in step b to obtain a compact, and drying the compact;

[0043] d, vacuum sintering the compact dried in step c, and cooling to obtain a medical porous Ti-Mn-Cu alloy.

[0044] In a specific embodiment, the mixing in step a is carried out on a ball mill, anhydrous ethanol is the ball milling medium, and t...

Embodiment 1

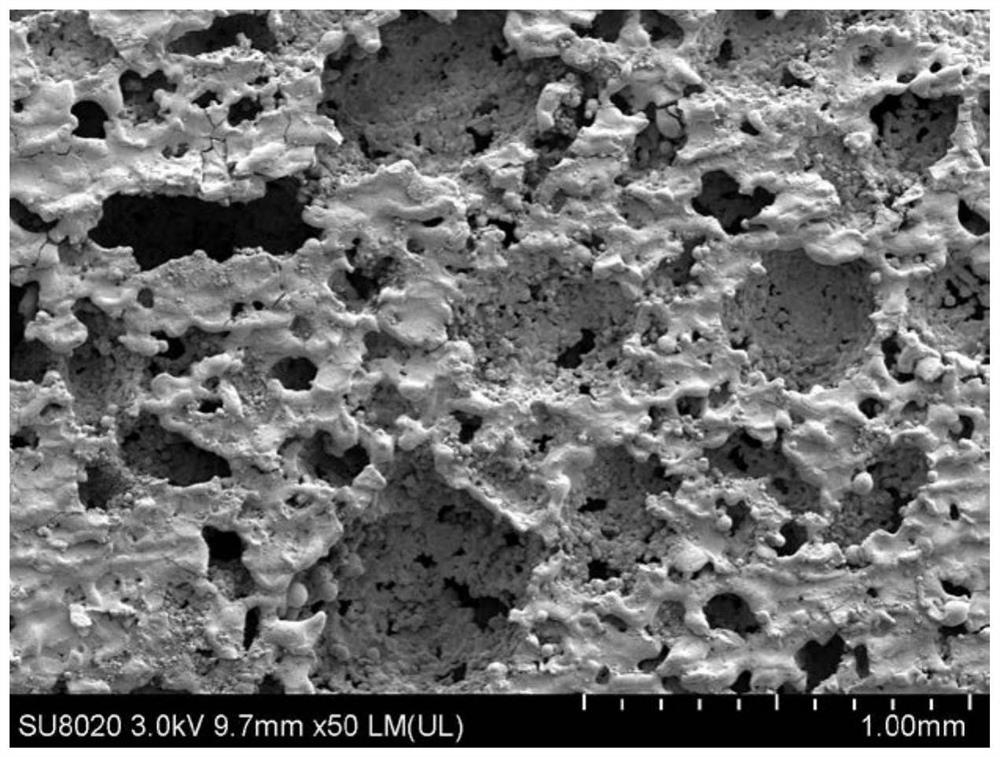

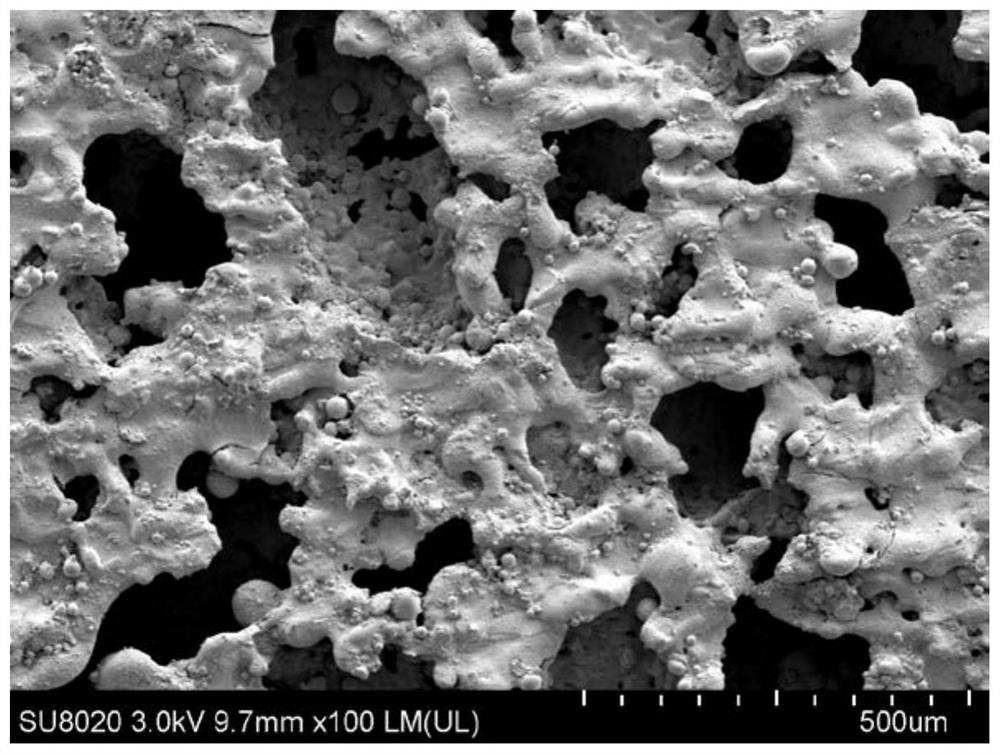

[0059] Weigh 2.5g manganese powder with a particle size of -400 mesh, 1.5g copper powder with a particle size of -400 mesh and 46g titanium powder with a particle size of -325 mesh, add absolute ethanol according to the liquid-solid ratio of 1.2ml:1g, and the ratio of ball to material is 10:1 The mixture was ball milled on a planetary ball mill at 300 rpm for 2 h, and dried at 60 °C for 10 h to obtain a Ti-Mn-Cu mixed powder. Weigh 4g of mixed powder, add 4g of ammonium bicarbonate granules, after mixing evenly, add 5wt% polyvinyl alcohol solution according to 0.01ml / g powder, and mix evenly again; put the mixture into a molding die, under 165MPa pressure Press for 3 minutes to obtain a compact. The compacts were dried in a graphite crucible at 60°C for 10 hours, and then vacuum sintered. The whole sintered at 10 -1 ~10 -3 Pa vacuum degree, firstly heated to 200℃ for 2h at 5℃ / min, then heated to 800℃ for 0.5h at 5℃ / min, finally heated to 1000℃ for 2h at 3℃ / min, cooled to ro...

Embodiment 2

[0061] Weigh 2.5g manganese powder with a particle size of -400 mesh, 2.5g copper powder with a particle size of -400 mesh and 45g titanium powder with a particle size of -325 mesh, add anhydrous ethanol according to the liquid-solid ratio of 1.2ml:1g, and the ratio of ball to material is 10:1 The mixture was ball milled on a planetary ball mill at 300 rpm for 2 h, and dried at 60 °C for 10 h to obtain a Ti-Mn-Cu mixed powder. Weigh 4g of mixed powder, add 4g of ammonium bicarbonate granules, after mixing evenly, add 5wt% polyvinyl alcohol solution according to 0.01ml / g powder, and mix evenly again; put the mixture into a molding die, under 165MPa pressure Press for 3 minutes to obtain a compact. The compacts were dried in a graphite crucible at 60°C for 10 hours, and then vacuum sintered. The whole sintered at 10 -1 ~10 -3 Pa vacuum degree, firstly heated to 200℃ for 2h at 5℃ / min, then heated to 800℃ for 0.5h at 5℃ / min, finally heated to 1000℃ for 2h at 3℃ / min, cooled to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com