Degradable photoresist and application thereof in 3D printing

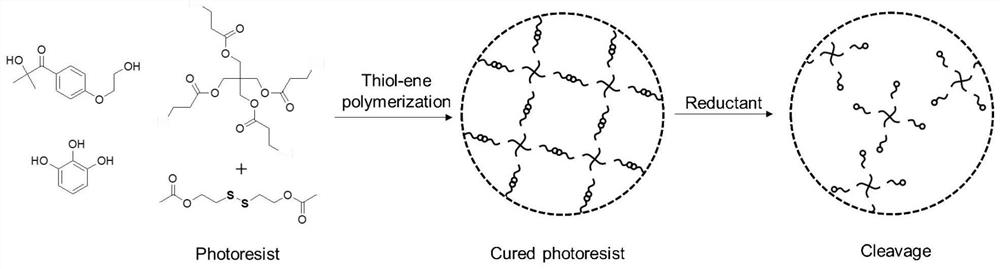

A 3D printing and photoresist technology, applied in the field of degradable photoresist preparation, can solve the problems of complex organic synthesis, difficult doping printing, harsh reaction conditions, etc., and achieve fast preparation, simple method and mild degradation conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of crosslinking agent main body with two acrylate double bonds and disulfide bonds

[0033] The specific steps are as follows:

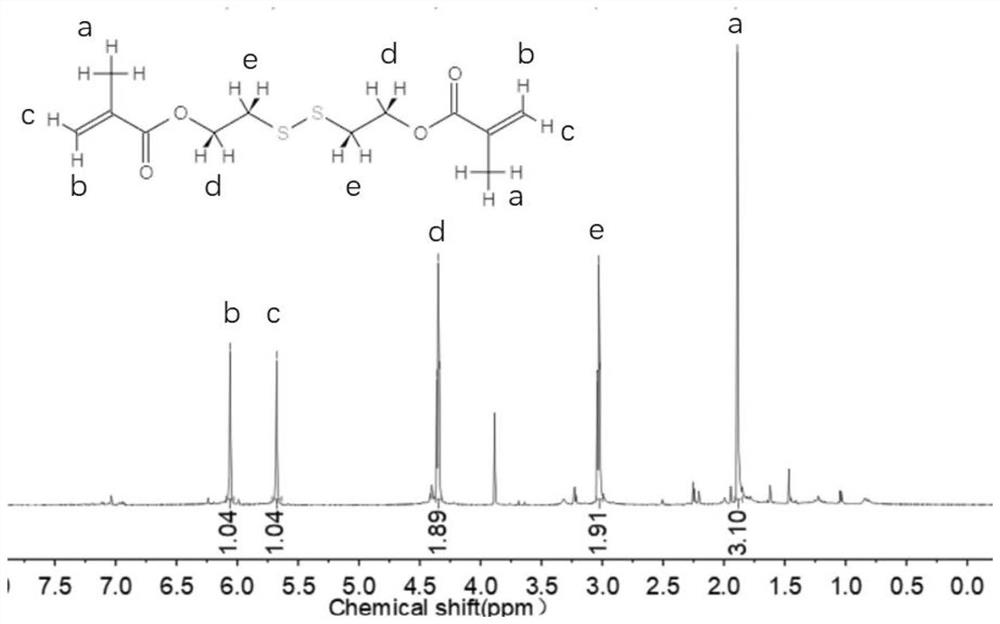

[0034] Bis(2-hydroxyethyl)disulfide and triethylamine in a molar ratio of 1:8 were dissolved in anhydrous tetrahydrofuran. Then, the flask containing the solution was immersed in an ice-water bath, and methacryloyl chloride with a molar equivalent of 4 was slowly added dropwise to the stirred mixed solution. The resulting heterogeneous mixture was stirred at 20°C for 24 hours, then filtered, evaporated to remove the solvent and the crude product was dissolved in chloroform. Then this solution was dissolved in 0.1mol / L Na 2 CO 3 washed three times in aqueous solution, then three times with deionized water, and finally with anhydrous MgSO 4 dry. Distillation under reduced pressure gave pale yellow liquid dimethyl dithioacrylate (DSDMA), which was stored in a refrigerator in the dark. That 1 HNMR spectrum as figure 2 show...

Embodiment 2

[0042] (1) Preparation of crosslinking agent main body with two acrylate double bonds and disulfide bonds

[0043] The specific steps are as follows:

[0044] Dissolve bis(2-hydroxyethyl) disulfide and triethylamine in a molar ratio of 1:4 in anhydrous tetrahydrofuran in an ice-water bath, and then add methacryloyl chloride (molar equivalent of 4) drop by drop during stirring. ), the reaction was stirred at room temperature for 24 hours, and the solvent was removed by filtration under reduced pressure. Use 0.2M Na for the crude product 2 CO 3 It was washed three times, and further purified by silica gel-60 column chromatography with chloroform as mobile phase. The final dithiodimethacrylate product is a yellowish liquid and is stored in the refrigerator away from light.

[0045] (2) Preparation method of degradable photoresist

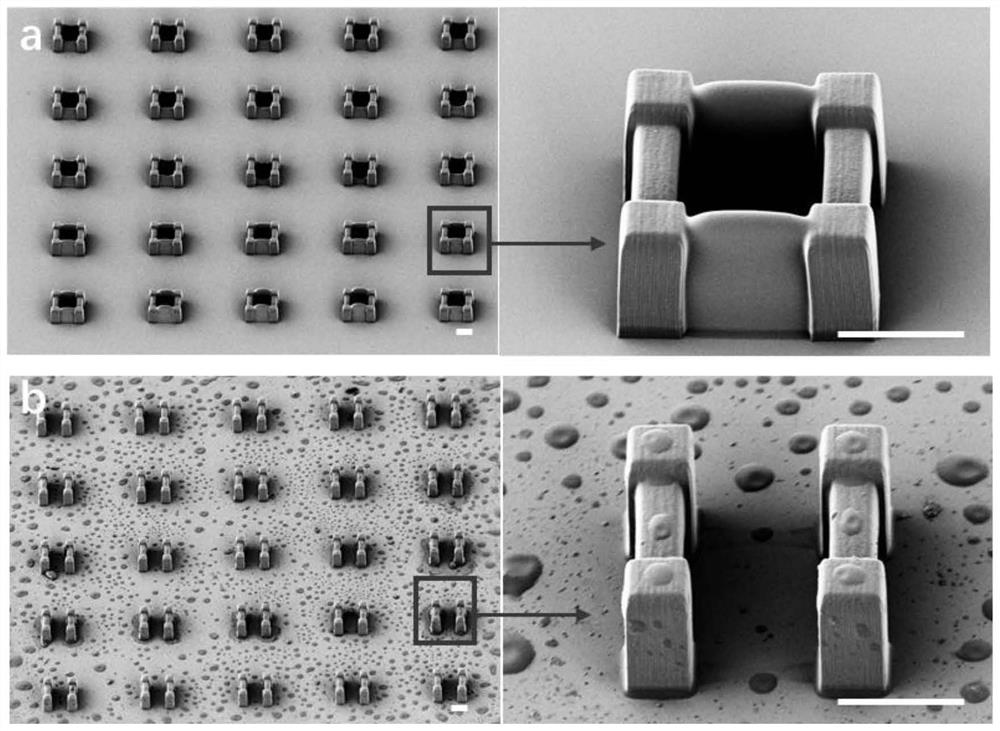

[0046] The ratio of double bonds in the photopolymerizable monomer and the photopolymerizable crosslinking agent is 1:1, and then the light absor...

Embodiment 3

[0052] (1) Preparation of crosslinking agent main body with two acrylate double bonds and disulfide bonds

[0053] The specific steps are as follows:

[0054] Dissolve bis(2-hydroxyethyl)disulfide and triethylamine in a molar ratio of 1:4 in anhydrous tetrahydrofuran in an ice-water bath, and then add methacryloyl chloride (molar equivalent of 2) drop by drop during stirring. ), the reaction was stirred at room temperature for 24 hours, and the solvent was removed by filtration under reduced pressure. Use 0.1M Na for crude product 2 CO 3 The solution was washed three times and further purified by silica gel-60 column chromatography using chloroform as mobile phase. The final dithiodimethacrylate product is a yellowish liquid and is stored in the refrigerator away from light.

[0055] (2) Preparation method of degradable photoresist

[0056] The ratio of double bonds in the photopolymerizable monomer and the photopolymerizable crosslinking agent is 1:2, and then the light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com