Scratch-resistant water-based gloss oil and preparation method thereof

A water-based varnish and scratch-resistant technology, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems that the friction coefficient cannot be met, the friction coefficient of the packaging surface is low, and the surface of the medicine box is easy to be scratched. Achieve no irritating odor, improve scratch resistance, enhance strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

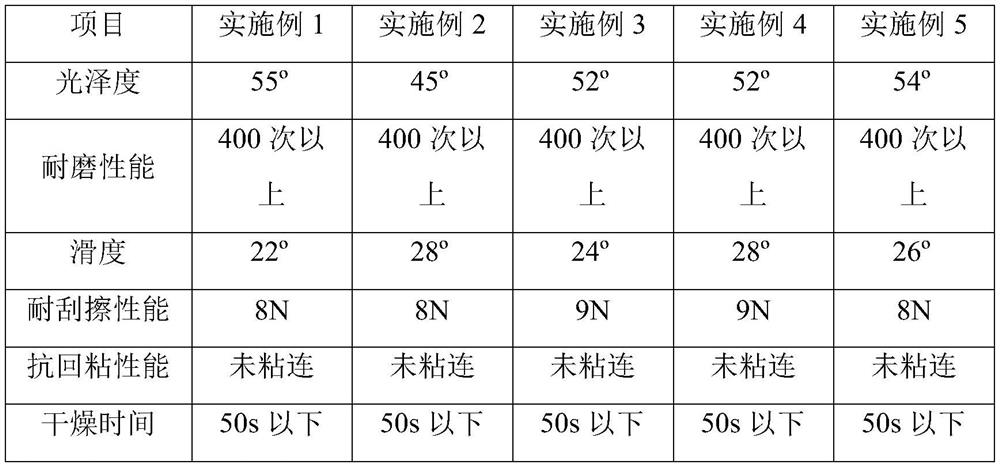

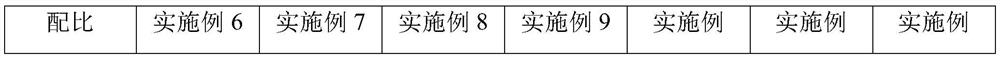

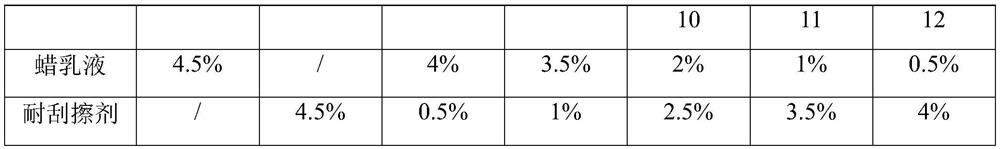

Examples

preparation example Construction

[0039] The scratch-resistant water-based varnish of the present application is preferably prepared by the following preparation method, and the prepared varnish is of excellent quality. The preparation method designed by this application includes the following steps:

[0040] S1, according to the formula amount, pour deionized water into the container, add the water-soluble acrylic resin of the formula amount, and then continue to stir for more than 20min;

[0041] S2, under stirring conditions, slowly add the leveling agent, wetting agent, anti-scratch agent and antifoaming agent of the formula to the mixed solution obtained in step S1 successively, and then continue to stir for more than 10min;

[0042] S3, under stirring conditions, successively add the polyacrylate emulsion, polyurethane-acrylate resin and wax emulsion of formula amount to the mixed solution obtained in step S2, and then continue to stir for more than 30min;

[0043] S4, under stirring conditions, add the...

Embodiment 1

[0057] The scratch-resistant water-based varnish in this embodiment has the following components and mass percentages: 25% of polyacrylate emulsion, 25% of polyurethane-acrylate resin, 35% of water-soluble acrylic resin, and a polymer with a particle size of 0.5-0.6 μm. Propylene wax wax emulsion 5%, film-forming aid 0.75%, Digao 482 leveling agent 0.25%, Surfynol OP-340 wetting agent 0.5%, defoamer 0.5%, Dow Corning DC-51 scratch resistance agent 1.4%, Deionized water 6.6%.

[0058] The scratch-resistant water-based varnish of the present embodiment is prepared by the following process steps:

[0059] S1. According to the formula amount, pour deionized water into the container, the stirring speed is 400rpm / min, add the formula amount of acrylic resin, and then continue to stir for 20min.

[0060] S2, with the stirring speed of 400rpm / min, under stirring conditions, slowly add the leveling agent, wetting agent, anti-scratching agent and defoaming agent of the formula to the m...

Embodiment 2

[0064] The scratch-resistant water-based varnish in this embodiment has the following components and mass percentages: 25% of polyacrylate emulsion, 30% of polyurethane-acrylate resin, 32% of water-soluble acrylic resin, and polytetrafluoroethylene with a particle size of 0.8-1 μm. Vinyl fluoride wax wax emulsion 2%, film-forming aid 1.5%, Digao 482 leveling agent 0.2%, OT75 wetting agent 1%, mixed defoamer 0.1%, nanosil4040 scratch resistance agent 2%, deionized water 6.2% %.

[0065] The scratch-resistant water-based varnish of the present embodiment is prepared by the following process steps:

[0066] S1. According to the formula amount, pour deionized water into the container, the stirring speed is 400rpm / min, add the water-soluble acrylic resin of the formula amount, and then continue to stir for 20min.

[0067] S2, with a stirring speed of 400rpm / min, under stirring conditions, slowly add the leveling agent, wetting agent, scratch resistance agent and defoaming agent of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com