Evaluation system for MEMS gas sensor

A gas sensor and gas technology, applied in the field of evaluation systems, can solve the problems of test gas environmental pollution, unstable test environment, low degree of automation, etc., to increase the relative adsorption area, improve air tightness and result accuracy, measurement Precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

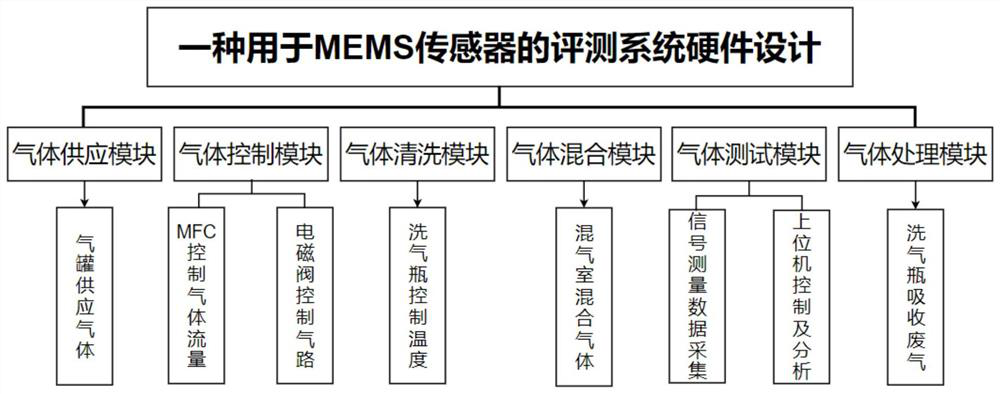

[0025] A MEMS gas sensor detection device is provided, such as figure 1 As shown, it includes a gas supply module, a gas control module, a gas cleaning module, a gas mixing module, a gas testing module and a gas processing module.

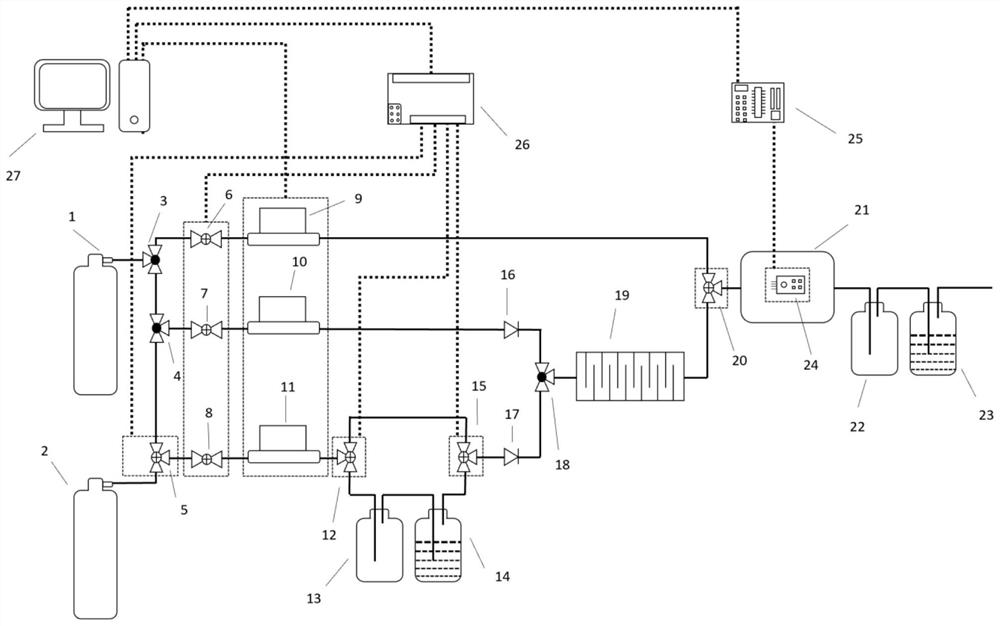

[0026] Specifically, as figure 2 As shown, the MEMS gas sensor detection system includes nitrogen cylinder 1, other gas cylinders 2, all-way three-way valves 3, 4, 18, two-position three-way solenoid valves 5, 12, 15, 20, and two-position two-way solenoid valves 6, 7, 8, MFC9, 10, 11, buffer bottle 13, 22, gas washing bottle 14, 23, one-way valve 16, 17, gas mixing chamber 19, cavity 21, standard gas sensor 24, microcontroller 25, PLC26 and PC27.

[0027] Specifically, the gas path adopts a silicone tube with an inner diameter of 6.5 mm and an outer diameter of 10 mm, and the joint between the device and the silicone tube adopts a two-point turn quick-release joint.

[0028] Specifically, one end of the above-mentioned two-point rotary quick re...

Embodiment 2

[0040] A method for detecting MEMS gas sensors under different humidity conditions in a test system is proposed:

[0041] Specifically, as Figure 5 As shown, the host computer software in the PC27 inputs the program into the PLC26 through the network port 113, and sets the PLC to the RUN mode, the 24V DC power supply 101 supplies power to the PLC, and the 24V DC power supply 103 forms a loop with all the reset buttons to connect to the terminal 102, etc. To supply power to the input signal, the 24V DC power supply 112 supplies power to the solenoid valve.

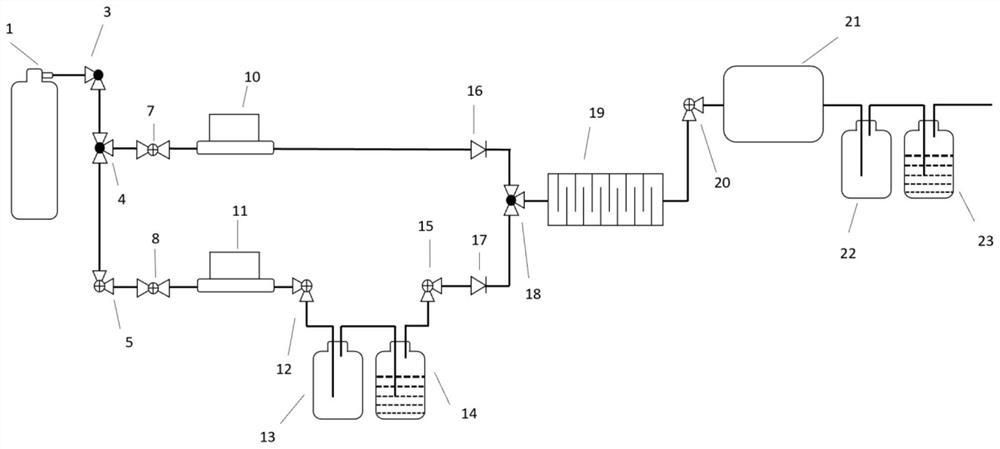

[0042] Specifically, as image 3 As shown, open the nitrogen bottle 1 to make nitrogen flow into the system, which is the two-position two-way solenoid valve 6, and the two-position three-way solenoid valve 20 is energized to conduct the first passage.

[0043] Specifically, connect the MFC9 to the computer to set the nitrogen flow rate and enter the cavity. After stabilization, record the MEMS gas sensor and standard ga...

Embodiment 3

[0049] A method for detecting MEMS gas sensors under dry mixed gas conditions in the test system is proposed:

[0050] Specifically, as Figure 5 As shown, the host computer software in the PC27 inputs the program into the PLC26 through the network port 113, and sets the PLC to the RUN mode, the 24V DC power supply 101 supplies power to the PLC, and the 24V DC power supply 103 forms a loop with all the reset buttons to connect to the terminal 102, etc. To supply power to the input signal, the 24V DC power supply 112 supplies power to the solenoid valve.

[0051] Specifically, the nitrogen cylinder 1 is turned on to allow nitrogen to flow into the system, which is the two-position two-way solenoid valve 6, and the two-position three-way solenoid valve 20 is energized to conduct the first passage.

[0052] Specifically, connect the MFC9 through the computer, set the nitrogen flow rate and enter the cavity, and record the MEMS gas sensor and standard gas sensor readings displaye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com