Method for preparing lithium-sulfur battery diaphragm material by using fluorine-containing covalent organic framework material

A covalent organic framework, lithium-sulfur battery technology, used in lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve problems such as low capture strength and efficiency, imperfect related mechanisms, and inappropriate pore size , to achieve the effect of simple synthesis, inhibition of shuttle effect, and excellent discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

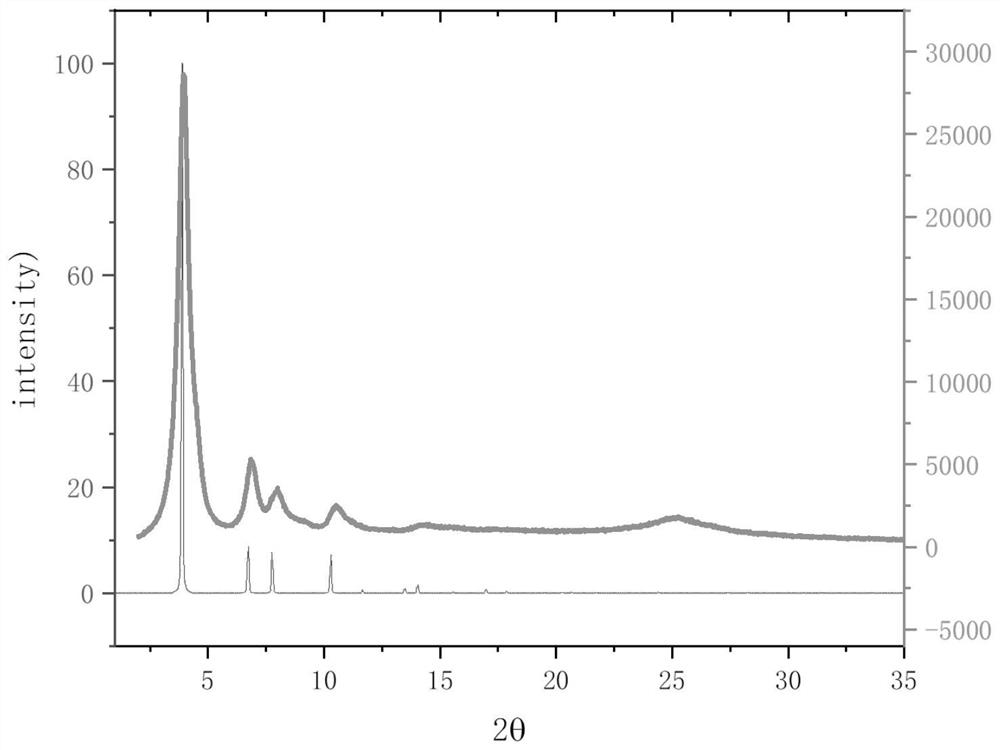

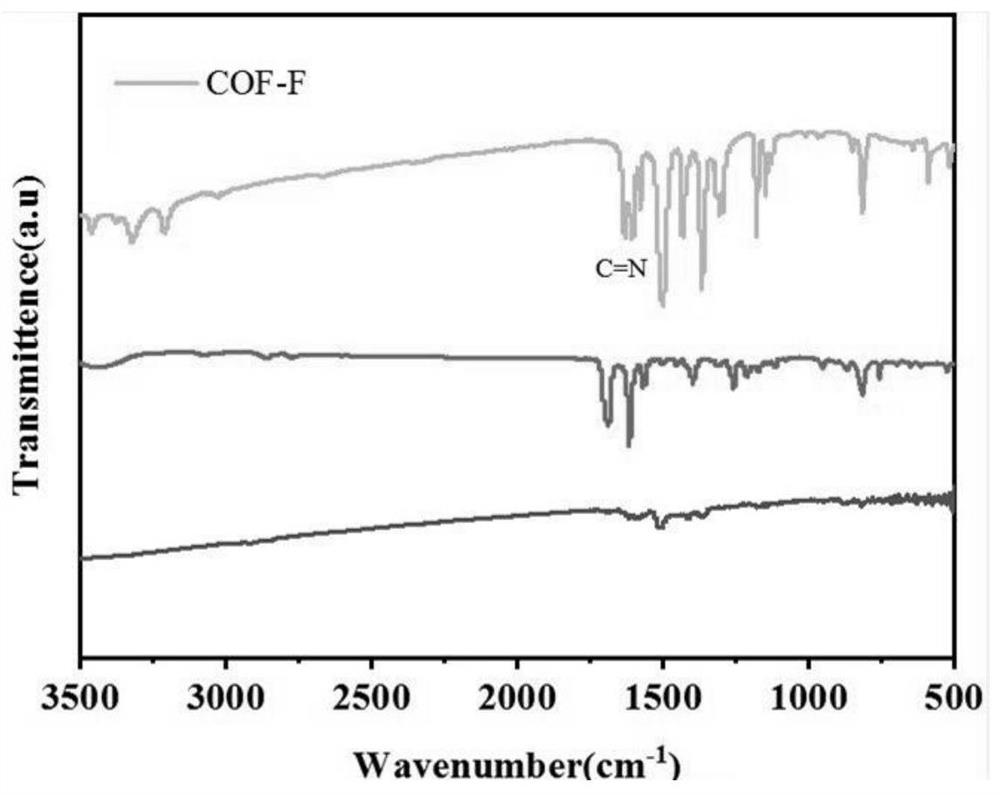

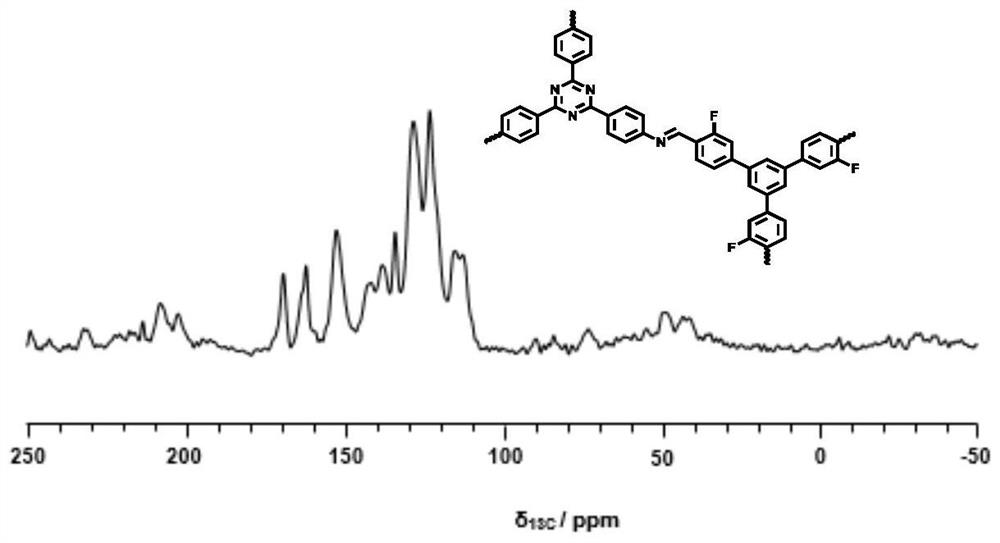

[0049] Fluorine-containing covalent organic framework material (COF-F): 200 mg (0.55 mmol) of 2, 4, 6 tris(4-aminophenyl)-1, 3, 5-triazine and 250 mg of 1,3,5-tris( 3-Fluoro-4-formylphenyl)benzene (0.55mmol) was added to a 50ml thick-walled pressure bottle, 50ml 1,4-dioxane, 50ml o-chlorobenzene and 10ml glacial acetic acid were added after sonication , seal the pressure bottle, sonicate for 5-10 minutes, and quickly freeze it in a liquid nitrogen bath for 2-5 minutes; then vacuum the pressure bottle, fill it with argon, seal it, and thaw it to room temperature. After 3 cycles of "freezing" - Thaw" process, i.e. degassing through three pump freeze-thaw cycles. Then, the temperature was raised to 120°C at a heating rate of 5°C / min for 3 days, and the product was obtained by centrifugation, and washed three times with acetone and tetrahydrofuran alternately. Finally, the product COF-F was dried under vacuum at 80 °C for 8 hours to obtain the covalent organic framework material ...

Embodiment 2

[0051] Fluorine-free covalent organic framework material (COF-NF): add 2,4,6-tris(4-aminophenyl)triazine (53.2mg, 0.15mmol), 1,3 to a 15ml thick-walled pressure bottle , 5-tris(4-formylphenyl)benzene (58.6 mg, 0.15 mmol), 2 mLo-DCB, 2 mL n-butanol and 0.4 mL 6M aqueous acetic acid. The thick-walled pressure bottle was first sonicated for 30 minutes to form a bulk solid, then flash frozen at 77k (in a liquid nitrogen atmosphere) and degassed through three pump freeze-thaw cycles. The tube was sealed, and then the temperature was raised to 120°C at a ramp rate of 5°C / min and the reaction was incubated for 3 days. The bright yellow precipitate was washed three times with acetone and collected by filtration. Finally, the powder was dried in a vacuum oven at 80°C.

Embodiment 3

[0053] The other steps are the same as in Example 1, except that the constant temperature reaction time is replaced by 5 days from 3 days. , when the replacement is 5 days, the COF-F material can still be synthesized but the structure is unstable and the crystallinity is low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com