Two-dimensional carbon/boron-titanium dioxide composite oxide, preparation method thereof and application of two-dimensional carbon/boron-titanium dioxide composite oxide in photocatalytic hydrogen production

A composite oxide and titanium dioxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of loose contact structure, unfavorable transmission, etc. Good controllability and repeatability, mild reaction conditions and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of two-dimensional carbon / boron-titanium dioxide composite oxide, specifically:

[0038] Add 150 mg Ti to 15 mL of deionized water 3 C 2 , after stirring evenly, first add 2mmol boric acid, then add 0.5mL hydrogen peroxide solution with a mass concentration of 30wt%, stir for 10min, transfer to a polytetrafluoroethylene-lined autoclave, and place it in a blast drying box. The thermal reaction is carried out at 160° C. for 8 hours. After the reaction, the product is washed, separated and dried to obtain a two-dimensional carbon / boron-titanium dioxide composite.

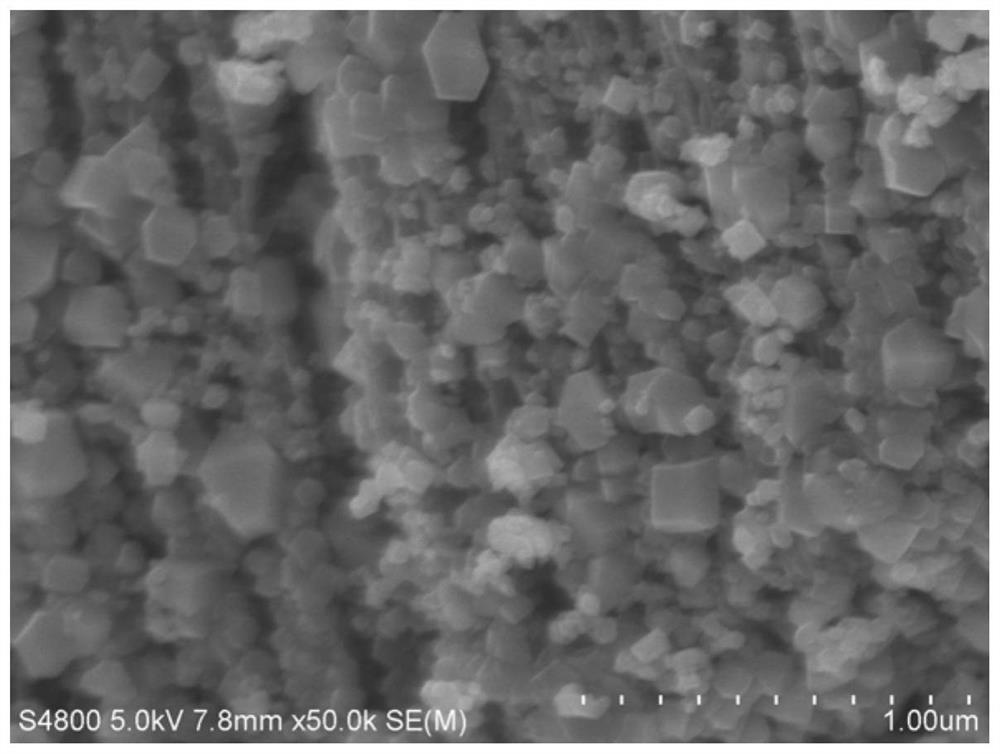

[0039] The SEM characterization of the as-synthesized 2D carbon / boron-titania composites is as follows: figure 1 shown in the figure 1 It can be seen that the composite has a two-dimensional layered structure; Figure 5A middle a, Figure 5B The XRD crystal form shown in a shows that the generated product contains anatase titanium dioxide and C; Figure 6A The XPS image in a shows tha...

Embodiment 2

[0043] A preparation method of two-dimensional carbon / boron-titanium dioxide composite oxide, specifically:

[0044] Add 180mg Ti to 15mL deionized water 3 C 2 , after stirring evenly, first add 6 mmol boric acid, then add 1 mL of hydrogen peroxide solution with a mass concentration of 30 wt %, stir for 30 min, transfer it to a polytetrafluoroethylene-lined high-pressure reaction kettle, and place it in a blast drying box hydrothermally The reaction is carried out at 180° C. for 12 hours. After the reaction, the product is washed, separated and dried to obtain a two-dimensional carbon / boron-titanium dioxide composite.

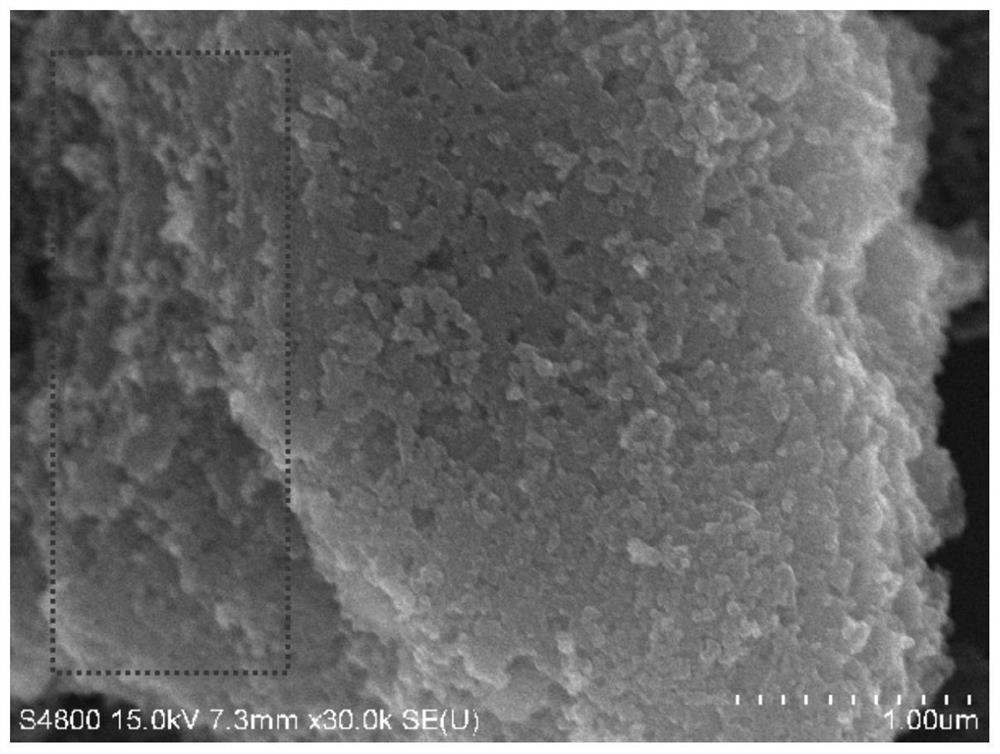

[0045] The SEM characterization of the as-synthesized 2D carbon / boron-titania composites is as follows: figure 2 shown, by figure 2 It can be seen that the composite has a two-dimensional layered structure; Figure 5A middle b. Figure 5B The XRD crystal form shown in b shows that the generated product contains anatase titanium dioxide and C; Figure 6A ...

Embodiment 3

[0049] A preparation method of two-dimensional carbon / boron-titanium dioxide composite oxide, specifically:

[0050] Add 210mg Ti to 15mL deionized water 3 C 2 , after stirring evenly, first add 10 mmol boric acid, then add 1.5 mL of hydrogen peroxide solution with a mass concentration of 30 wt %, stir for 50 min, transfer it to a polytetrafluoroethylene-lined autoclave, and place it in a blast drying box. The thermal reaction is carried out at 200° C. for 16 hours. After the reaction, the product is washed, separated and dried to obtain a two-dimensional carbon / boron-titanium dioxide composite.

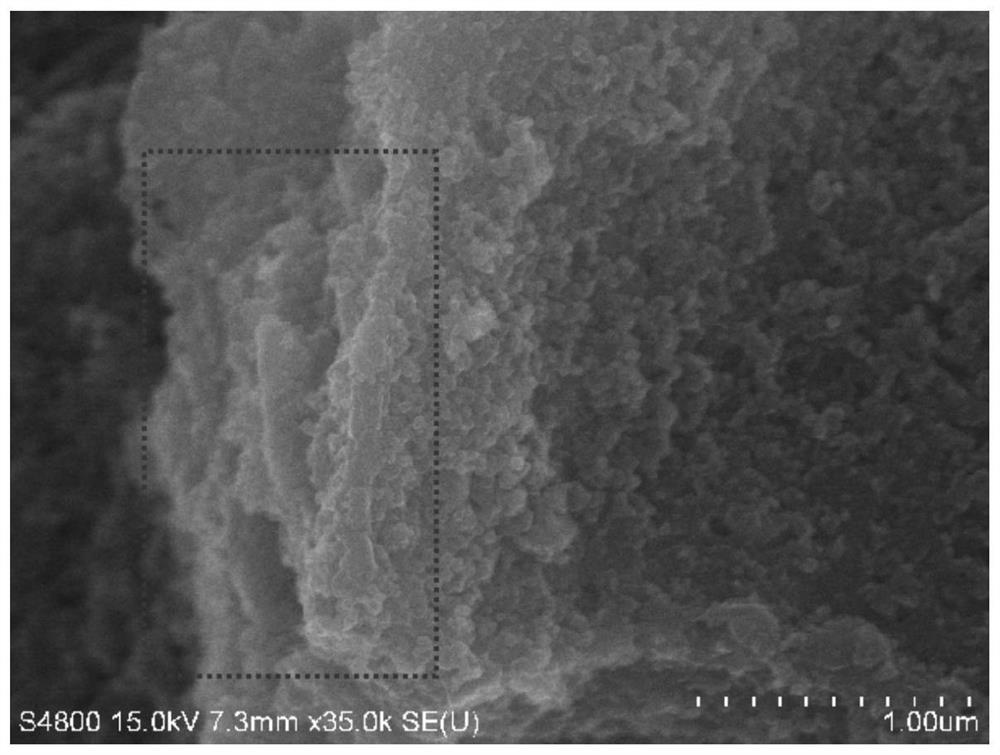

[0051] The SEM characterization of the synthesized two-dimensional carbon / boron-titania composite oxide is as follows: image 3 shown, by image 3 It can be seen that the composite has a two-dimensional layered structure; Figure 5A middle c. Figure 5B The XRD crystal form shown in c shows that the generated product contains anatase titanium dioxide and C; Figure 6A The XPS im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com