Preparation method and application of lubricating additive

A technology for lubricating additives and medicines, which is applied in the field of preparation of lubricating additives, can solve problems such as the preparation technology has not yet been established, and achieve the effects of improving drug loading efficiency, excellent lubrication and wear-reducing performance, and enhancing lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

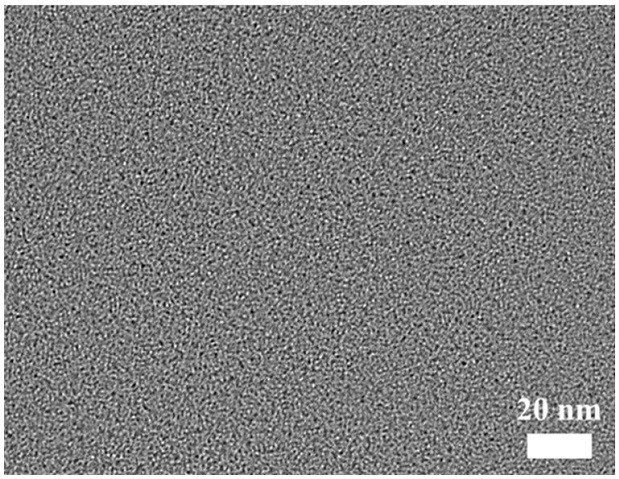

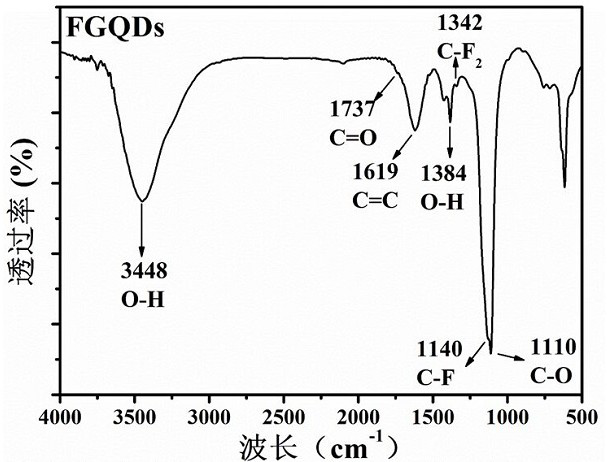

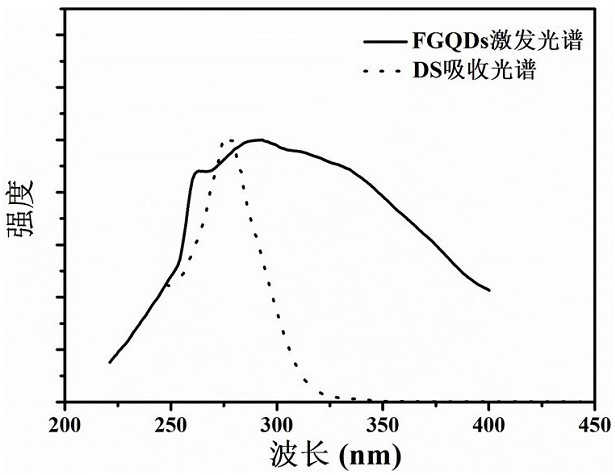

[0037] (1) Preparation of lubricant: Dissolve 15 mg of sodium hyaluronate (NaHA) solid in 1 mL of water and sonicate (200 W) until the solid is completely dissolved. A mixed solution of 0.5 mg of fluorinated graphene quantum dots (FGQDs) and 0.1 mg of DS was added, and sonicated (400 W) until uniformly dispersed to obtain 0.5 mg / mL of FGQDs-NaHA lubricant (fluorinated graphene quantum dots) The oxygen content is about 50%, and the fluorine content is about 30%; the molecular weight of sodium hyaluronate is 200,000 Da~400,000 Da).

[0038] (2) Tribological characterization of lubricants: The friction pair (zirconia balls and plates) were cleaned twice with ethanol (200 W) by ultrasonic waves, and the anhydrous ethanol was evaporated. Then, the friction coefficient of the prepared 0.5 mg / mL FGQDs-NaHA lubricant was tested with a TRB-3 reciprocating friction tester under the conditions of 5 N, 5 Hz, 25 °C, a reciprocating distance of 2 mm, and a test time of 30 min.

Embodiment 2

[0040] (1) Preparation of lubricant: Dissolve 15 mg of sodium hyaluronate (NaHA) solid in 1 mL of water and sonicate (200 W) until the solid is completely dissolved. Add a mixed solution of 1 mg of fluorinated graphene quantum dots (FGQDs) and 1 mg of DS, and ultrasonically (400W) to disperse uniformly to obtain 1 mg / mL of FGQDs-NaHA lubricant (containing fluorinated graphene quantum dots). The oxygen content is about 50%, and the fluorine content is about 30%; the molecular weight of sodium hyaluronate is 200,000 Da~400,000 Da).

[0041] (2) Tribological characterization of lubricants: The friction pair (zirconia balls and plates) were cleaned twice with ethanol (200 W) by ultrasonic waves, and the anhydrous ethanol was evaporated. Then, the friction coefficient of the prepared 1 mg / mL FGQDs-NaHA lubricant was tested with a TRB-3 reciprocating friction tester under the conditions of 5 N, 5 Hz, 25 °C, a reciprocating distance of 2 mm, and a test time of 30 min.

Embodiment 3

[0043](1) Preparation of lubricant: Dissolve 15 mg of sodium hyaluronate (NaHA) solid in 1 mL of water and sonicate (200 W) until the solid is completely dissolved. Add a mixed solution of 3 mg of fluorinated graphene quantum dots (FGQDs) and 2 mg of DS, and ultrasonically (400W) to disperse uniformly to obtain 3 mg / mL of FGQDs-NaHA lubricant (containing fluorinated graphene quantum dots). The oxygen content is about 50%, and the fluorine content is about 30%; the molecular weight of sodium hyaluronate is 200,000 Da~400,000 Da).

[0044] (2) Tribological characterization of lubricants: The friction pair (zirconia balls and plates) were cleaned twice with ethanol (200 W) by ultrasonic waves, and the anhydrous ethanol was evaporated. Then, the friction coefficient of the prepared 3 mg / mL FGQDs-NaHA lubricant was tested with a TRB-3 reciprocating friction tester under the conditions of 5 N, 5 Hz, 25 °C, a reciprocating distance of 2 mm, and a test time of 30 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com