Fe3O4-MnO2-CeO2 nano material as well as preparation method and application thereof

A nanomaterial and nanosheet technology is applied in the field of catalytic materials to achieve the effects of low cost, strong catalytic ability and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

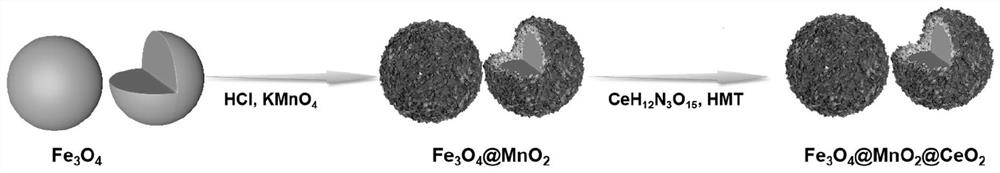

[0031] Example 1 Fe 3 O 4 @MnO 2 -CeO 2 Synthesis of Nanomaterials

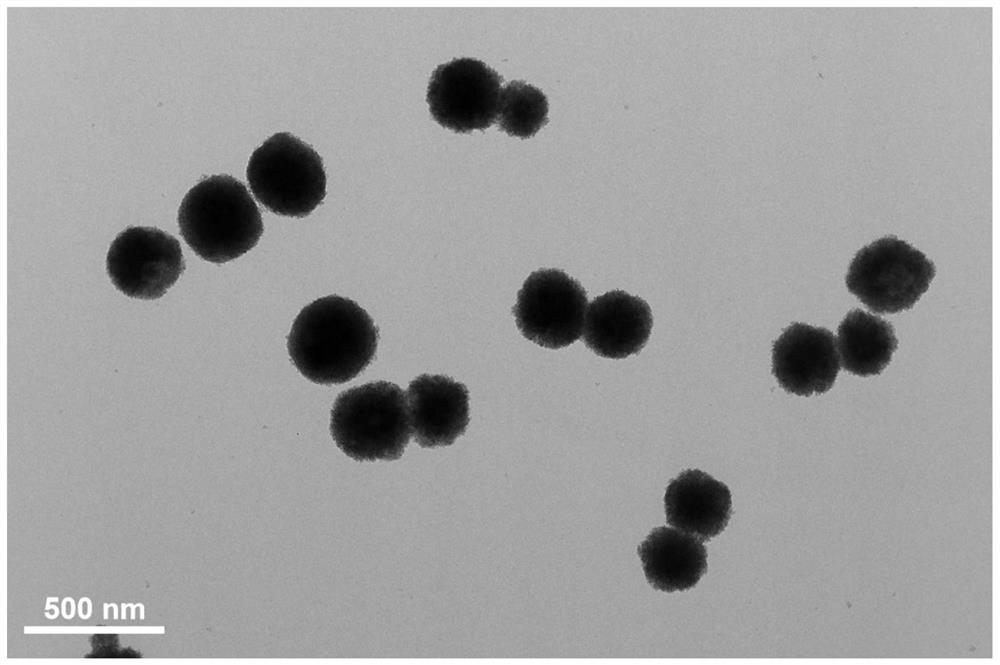

[0032] 1. Fe 3 O 4 Nanoparticles

[0033] 0.65g (4mmol) FeCl 3 and 0.20 g (0.78 mmol) of C 6 H 5 Na 3 O 7 Dissolve in 20mL (CH 2 OH) 2 Then, 1.20 g (14.6 mmol) of NaAc was added and stirred for 20 min; the reaction solution was transferred to a hydrothermal synthesis reactor at 200° C. for 10 h, cooled to room temperature, and repeatedly washed with deionized water-ethanol-deionized water for 3 times. collected and dried at 60 °C overnight to obtain the product Fe 3 O 4 Nanoparticles (Fe 3 O 4 NFs). to Fe 3 O 4 TEM characterization of the morphology as figure 2 , it can be seen that Fe 3 O 4 It is spherical, the surface is relatively smooth, and the particle size is about 160-250nm.

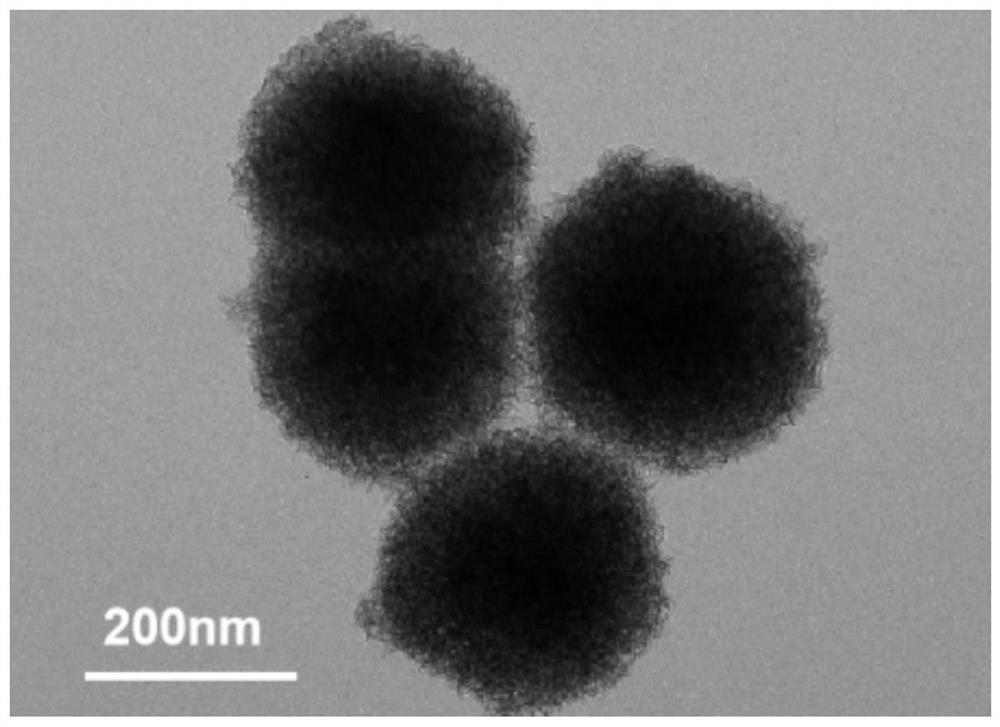

[0034] 2. Synthesis of Fe 3 O 4 @MnO 2

[0035] 0.1 g (0.43 mmol) Fe 3 O 4 The NFs were dispersed in 30 mL of deionized water under the action of ultrasound, and 0.2 g (1.27 mmol) of KMnO was slowly...

Embodiment 2

[0042] Example 2 Fe 3 O 4 @MnO 2 -CeO 2 Oxidase-like activity of nanomaterials

[0043] 1. Fe 3 O 4 @MnO 2 -CeO 2 Analysis of oxidase-like activity of nanomaterials.

[0044] (1) Take 285 μL and 282 μL of 0.2M acetic acid-sodium acetate buffer solution at pH 4.0 into each centrifuge tube in parallel, and add 0 μL and 3 μL of Fe to each centrifuge tube in turn. 3 O 4 @MnO 2 -CeO 2 NFs aqueous solution (1 mg / mL), 3 μL, 3 μL of 3,3',5,5'-tetramethylbenzidine anhydrous ethanol solution (TMB, 10 mM), and the above solutions were mixed evenly;

[0045] (2) the mixed solution prepared in step (1) was reacted at room temperature for 10min;

[0046] (3) Fe is removed by an external magnetic field 3 O 4 @MnO 2 -CeO 2 separated from the reaction liquid;

[0047] (4) Measure the ultraviolet absorption spectrum of the above mixed solution with an ultraviolet-visible absorption spectrophotometer, such as Image 6 A shown.

[0048] The result is as Image 6 As shown in A,...

Embodiment 3

[0055] Example 3 Fe 3 O 4 @MnO 2 -CeO 2 catalase-like activity of

[0056] 1. Fe 3 O 4 @MnO 2 -CeO 2 Analysis of catalase-like activity.

[0057] (1) Take three 285μL and 270μL 50mM, pH 7.0 phosphate buffers in parallel, and add 15μL Fe to each centrifuge tube in turn 3 O 4 @MnO 2 -CeO 2 Aqueous solution (1 mg / mL), then add 15 μL of 100 mM hydrogen peroxide, and mix the above solution evenly;

[0058] (2) the mixed solution prepared in step (1) was reacted at room temperature for 50min;

[0059] (3) Fe is removed by an external magnetic field 3 O 4 @MnO 2 -CeO 2 separated from the reaction liquid;

[0060] (4) measure the absorbance value at 240nM of above-mentioned mixed solution with ultraviolet-visible absorption spectrophotometer, the result is as follows Figure 7 A shown.

[0061] As shown in 7A, Fe 3 O 4 @MnO 2 -CeO 2 It can decompose hydrogen peroxide and has the ability to degrade hydrogen peroxide, so the nanomaterials synthesized in this exper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Michaelis constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com