Sorting system and method for fly ash non-porous floating beads

A sorting system and fly ash technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems affecting the quality of float beads, reduce the overall performance of float beads recycling, and save space. and water consumption, the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

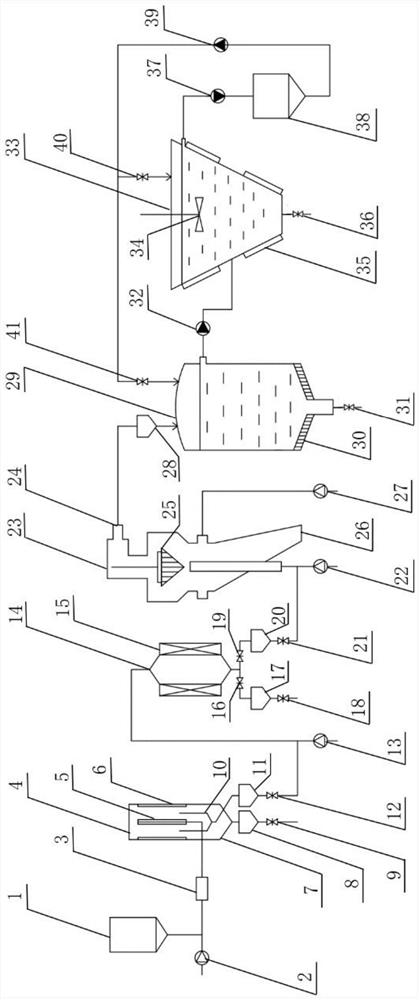

[0047] like figure 1 As shown, a sorting system for fly ash non-porous floating beads includes:

[0048] A preprocessing unit, a coarse bead sorting unit and a non-porous floating bead sorting unit connected in sequence;

[0049] The pretreatment unit includes a decarburization unit connected to the outlet of the ash hopper 1 receiving the fly ash, and the outlet of the decarburization unit is connected to the inlet of the demagnetization unit for decarburizing and demagnetizing the fly ash;

[0050] The floating bead coarse sorting unit includes a floating bead roughing machine 23 connected to the outlet of the demagnetization unit. The mixture of porous beads and non-porous beads in coal ash is sent to the non-porous beads separation unit;

[0051] The non-porous floating bead sorting unit includes a heater 29 connected to the outlet of the floating bead rougher 23, and a floater 33 connected to the outlet of the heater 29; The gas is separated out and the water vapor ent...

Embodiment 2

[0078] Based on the sorting system of fly ash non-porous floating beads in the first embodiment, a sorting method for non-porous floating beads is realized, including the following steps:

[0079] 1. The fly ash in the ash hopper 1 enters the friction charging chamber 3 under the action of the ash hopper fan 2, so that the carbon particles and the ash particles have different polarities and electric quantities, and the charged fly ash enters the carbon particle collection chamber 4 , the carbon particles move to the positive electrode rod 6 under the action of the electric field, and enter the carbon particle collector 8 through the carbon particle channel 7 , and at this time, the ash particles enter the ash particle collector 11 through the ash particle channel 10 .

[0080] 2. The ash particles in the ash particle collector 11 enter the magnetic bead collection chamber 14 under the control of the ash particle collector valve 12 and the ash particle fan 13, and the magnetic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com