Puncture-resistant insulating double-layer heat shrink tube and preparation method thereof

A double-layer heat-shrinkable tube, puncture-resistant technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the complex and cumbersome preparation process of double-layer sleeves, highly toxic hydrogen fluoride gas, high cost, etc. problem, to achieve the effect of eliminating the hidden danger of breakdown, high tear strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

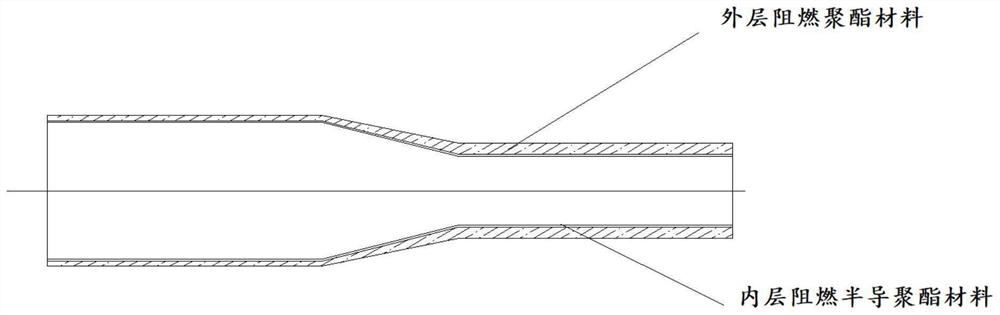

[0032] The embodiment of the present invention also provides a preparation method of a puncture-resistant insulating double-layer heat-shrinkable tube, comprising:

[0033] According to the formula of the above-mentioned puncture-resistant insulating double-layer heat-shrinkable tube, each raw material is weighed for standby;

[0034]The flame retardant polyethylene terephthalate, EPDM rubber graft modified acrylate, flame retardant thermoplastic elastomer material, polyethylene terephthalate-1,4-cyclohexanediol Methyl ester, polyethylene naphthalate, polytetramethylene terephthalate and antioxidant are mixed and granulated to obtain outer layer granules, which are for subsequent use;

[0035] The outer layer pellets and the inner layer pellets composed of conductive polyethylene terephthalate are placed in 70-80 ° C and under the pressure conditions of negative pressure -0.8 to -1 bar for drying treatment 2- After 4 hours, a double-layer tube is obtained by extrusion process...

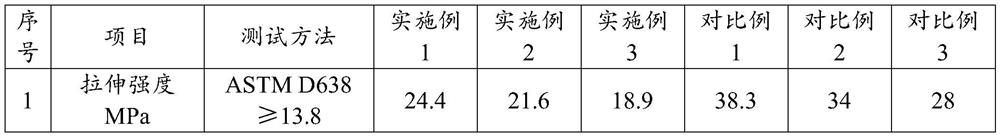

Embodiment 1

[0046] The outer layer is modified with commercially available flame retardant PET materials, and the specific components are as follows: 50 parts of flame retardant PET (JC-G530-N-HI, Jiangsu Jiuchuan), 5 parts of EPDM-DICP prepared above, and flame retardant TPE 5 parts (Shanghai Huahe 45A), 3 parts of PETG, 3 parts of PEN, 1 part of PBT and 0.5 part of antioxidant, the above components are mixed and granulated for later use. The inner layer is made of commercially available conductive PET material (nairui PET-NRVC7463). Before extrusion, the outer layer of flame retardant polyester material and the inner layer of the pellets made of semi-conductive polyester material should be dried at 75°C in a drying box under negative pressure -0.9bar to remove water for 3 hours. The raw materials are extruded into double-layer pipes that are extruded through the combined unit. The extruded tube blanks are cooled by cooling water after leaving the extrusion die, and then vacuum expanded ...

Embodiment 2

[0048] The outer layer is modified with commercially available flame retardant PET materials, and the components and mass parts are as follows: 50 parts of flame retardant PET (Yuyao Beihua 3030F), 10 parts of EPDM-DICP prepared above, and 5 parts of flame retardant TPE (Shanghai Hehe Co., Ltd.). Hua 50A), 3 parts of PETG, 3 parts of PEN, 1 part of PBT and 0.5 part of antioxidant, the above components are mixed and granulated for later use. The inner layer is made of commercially available conductive PET material (nairui PET-NRVC7463). Before extrusion, the outer layer of flame retardant polyester material and the inner layer of the pellets made of semi-conductive polyester material should be dried at 75°C in a drying box under negative pressure -0.9bar to remove water for 3 hours. The raw materials are extruded into double-layer pipes that are extruded through the combined unit. The extruded tube blanks are cooled by cooling water after leaving the extrusion die, and then vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com