High-salinity alkali liquor pool wastewater treatment process

A technology of salinity lye and high salinity, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, alkali metal compounds, etc., can solve the problem of yellow crystal color, inability to directly recover sodium sulfite products, difficult Fluorine drops below 30ppm, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

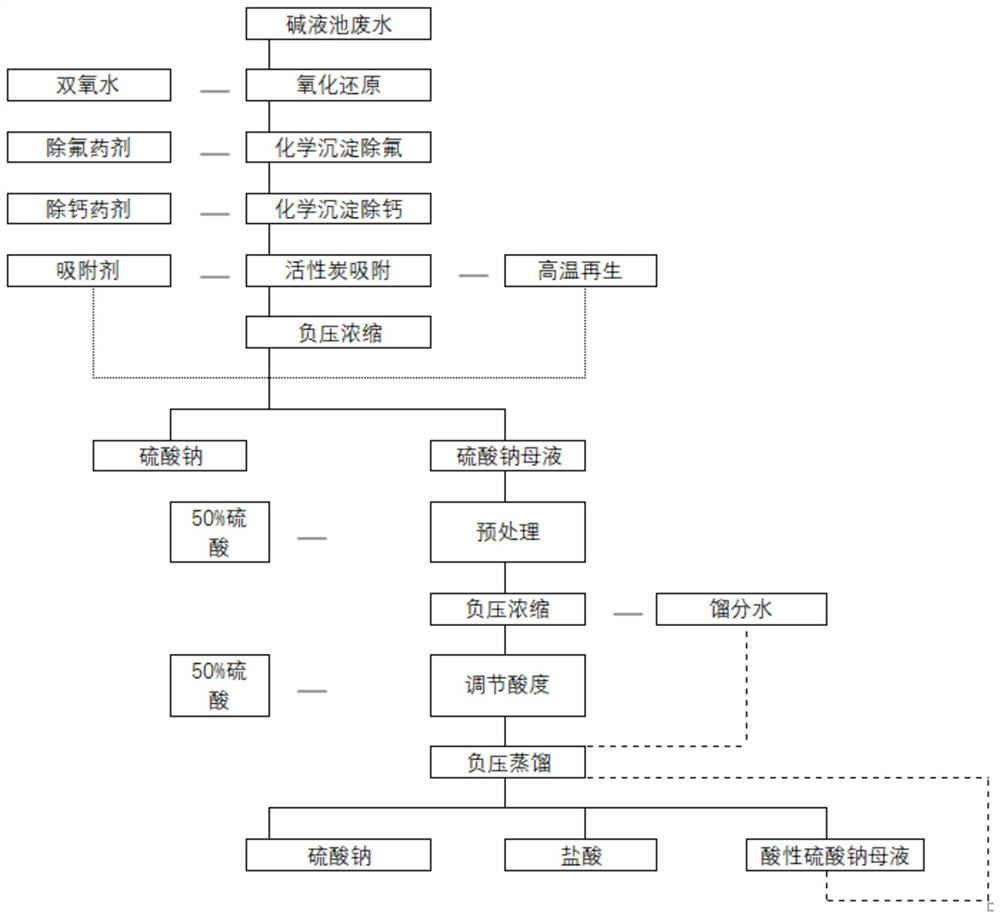

Method used

Image

Examples

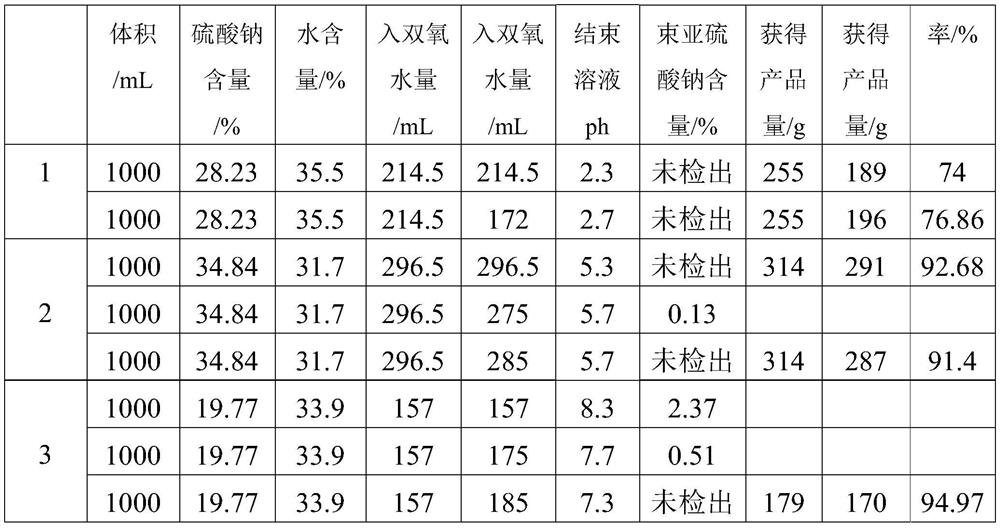

Embodiment 1

[0034] Take 500mL of lye pool wastewater, in which fluorine: 240ppm, chlorine 3.4g / L, sodium sulfite content 21.6%, hydrogen peroxide content 35.3%; calculate the amount of hydrogen peroxide used 82.5mL, and the amount of lime added 0.508g. Slowly add hydrogen peroxide dropwise at a rate of 5ml / min, control the reaction temperature to be less than 60°C, and detect the pH value change. After the solution becomes acidic, add liquid alkali to adjust pH=5.5. After the dropwise addition of hydrogen peroxide is completed, stir for 10min and detect the sodium sulfite content of 0%. (not detected), weigh lime and dissolve it in 50 mL of water, slowly add it to the solution, stir and react for 1 h, take a sample to detect the fluoride ion content of 22 ppm, weigh 0.3 g of sodium carbonate and add it to the solution and stir for 40 min, and take a sample to detect calcium ions The content is 47ppm, qualified, and suction filtration is started. The temperature of the filtrate is 37℃, and ...

Embodiment 2

[0036] Take 300mL of lye pool wastewater, including fluorine: 500ppm, chlorine 7.8g / L, sodium sulfite content 15.7%, hydrogen peroxide content 34.7%; the calculated amount of hydrogen peroxide used is 36.6mL, and the amount of lime added is 0.602g. Slowly add hydrogen peroxide dropwise at a rate of 5ml / min, control the reaction temperature to be less than 60°C, and detect the pH value change. After the solution becomes acidic, add liquid alkali to adjust pH=5.3. After the dropwise addition of hydrogen peroxide is completed, stir for 10min to detect the sodium sulfite content of 0%. (not detected), weigh lime and dissolve it in 50 mL of water, slowly add it to the solution, stir and react for 1 h, take a sample to detect the fluoride ion content of 11 ppm, weigh 0.27 g of sodium carbonate and add it to the solution and stir for 40 minutes, and take a sample to detect calcium ions The content was 59ppm, qualified, and suction filtration was started. The temperature of the filtrat...

Embodiment 3

[0038] Take 1000mL of lye pond wastewater, including fluorine: 877ppm, chlorine 17.9g / L, sodium sulfite content 30.8%, hydrogen peroxide content 35.9%; calculate the amount of hydrogen peroxide used 231.5mL, and the amount of lime added 4.01g. Slowly add hydrogen peroxide dropwise at a rate of 5mL / min, control the reaction temperature to be less than 60°C, and detect the pH value change. After the solution becomes acidic, add liquid alkali to adjust pH=5.9. After the hydrogen peroxide is added dropwise, stir for 10min to detect the sodium sulfite content of 0%. (not detected), weigh lime and dissolve it in 50mL of water, slowly add it into the solution, stir and react for 1h, take a sample to detect the fluoride ion content of 25ppm, weigh 1.1g of sodium carbonate and add it to the solution and stir for 40min, and take a sample to detect calcium ions The content is 22ppm, qualified, and suction filtration is started. The temperature of the filtrate is 51℃, and then it is adsorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com