Modified vinyl silane as well as preparation method and application thereof

A technology of vinyl silane and dimethyl siloxane, which is applied in the field of modified vinyl silane and its preparation, can solve the problems of weak powder dispersibility, reduced physical properties, and unstable performance, so as to improve grafting ability , Powder dispersion is good, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

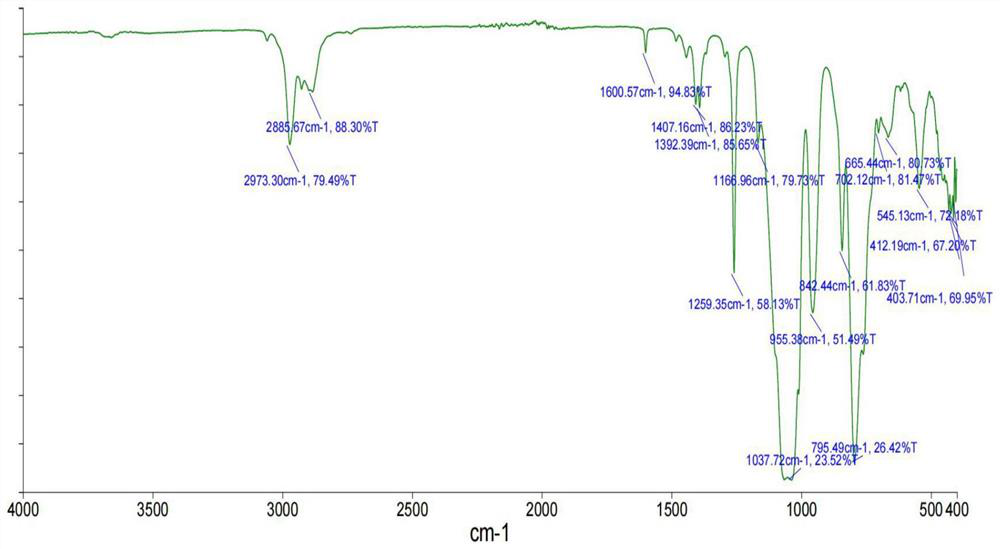

[0042] The present invention provides the preparation method of the modified vinyl silane described in the above technical solution, comprising the following steps:

[0043] Mixing vinyl silane, modifying reagent, catalyst and water to carry out modification reaction to obtain modified vinyl silane;

[0044] The vinylsilane includes vinyltrialkoxysilane; the vinyltrialkoxysilane includes vinyltrimethoxysilane, vinyltriethoxysilane, vinyltripropoxysilane or vinyltrialkoxysilane isopropoxysilane;

[0045] The modifying reagent includes silicone oil or dimethylsiloxane ring;

[0046] The silicone oil has the structure of formula II:

[0047] m=1~50;

[0048] The dimethylsiloxane ring body has the structure shown in formula III:

[0049] n=2-8.

[0050] In the present invention, unless otherwise specified, the required preparation raw materials are all commercially available products well known to those skilled in the art.

[0051] The present invention mixes vinylsilane...

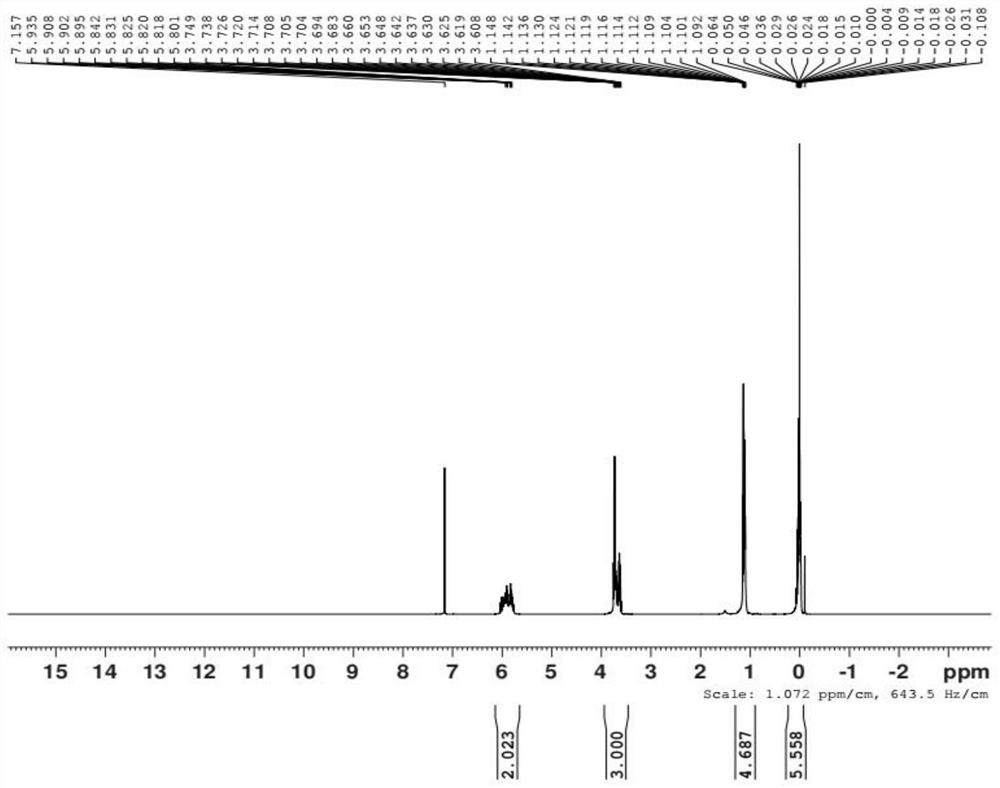

Embodiment 1

[0070] 100kg vinyl triethoxysilane was pumped into the 500L reactor, then 50kg DMC (dimethylsiloxane ring body) was added, the temperature was raised to 60°C, and 5kg water and 0.015kg hydroxide were added dropwise to the resulting mixture. The mixed solution of potassium was added dropwise for 0.5h, and the temperature was kept at 70°C for 3h. Sampling and analysis showed that the vinylsilane content in the product was less than 10%. The temperature was raised to 80°C, and the total amount of ethanol was extracted to 25kg. The obtained product was cooled and filtered. , to obtain 130kg of colorless and transparent modified vinyl silane product with a product viscosity of 5mPa / s;

[0071] The structural formula of the modified vinyl silane prepared in this example is:

[0072] x=2.

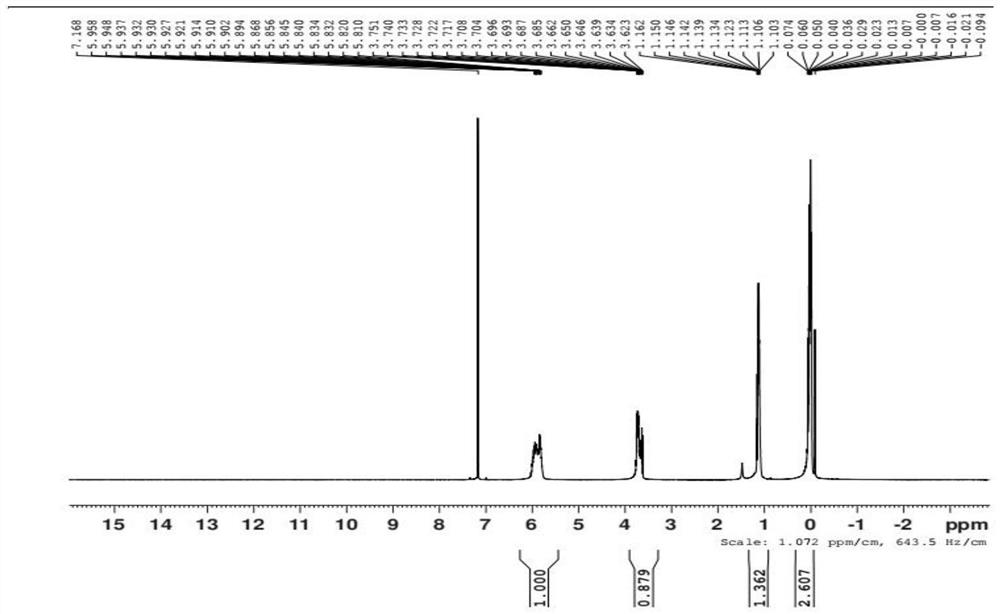

Embodiment 2

[0074] 100kg vinyl triethoxysilane was pumped into the 500L reactor, then 50kg DMC (dimethylsiloxane ring body) was added, the temperature was raised to 60°C, and 10kg water and 0.03kg hydroxide were added dropwise to the resulting mixture. The mixed solution of potassium was added dropwise for 1 h; the temperature was kept at 70 °C, the reaction was carried out for 3 h, and the content of vinylsilane in the product was less than 10%. , the finished product is 110kg, and the product viscosity is 20mPa / s;

[0075] The structural formula of the modified vinyl silane prepared in this example is:

[0076] x=4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com