Method for detecting furfural content based on up-conversion fluorescence nano system

A detection method and fluorescent nanotechnology, applied in fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of long detection time, high manpower requirements, and high detection cost, and achieve low detection limit, high detection accuracy and sensitivity, and strong fluorescence. Responsive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

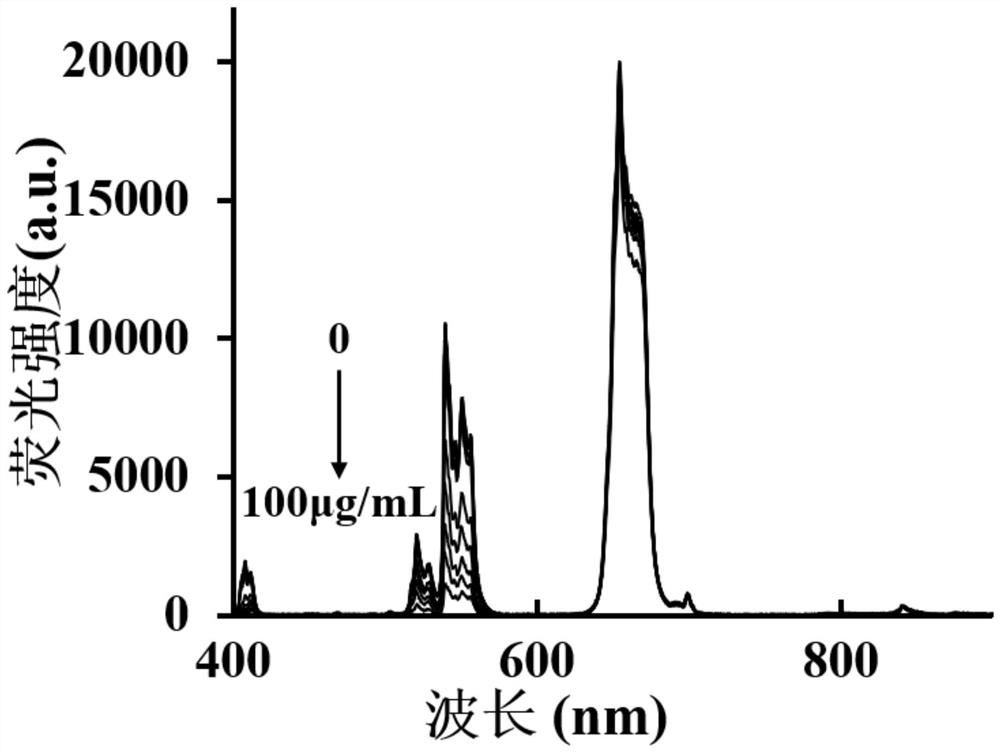

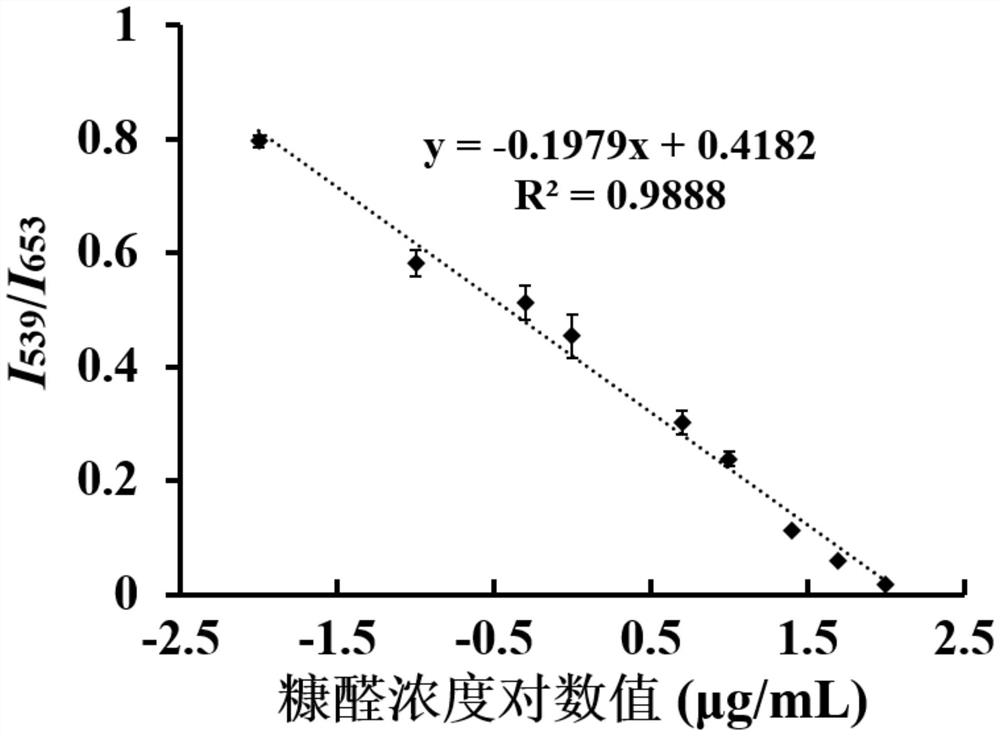

[0033] The invention discloses a method for detecting furfural content in food based on an up-conversion and p-toluidine-specific system. The specific steps are:

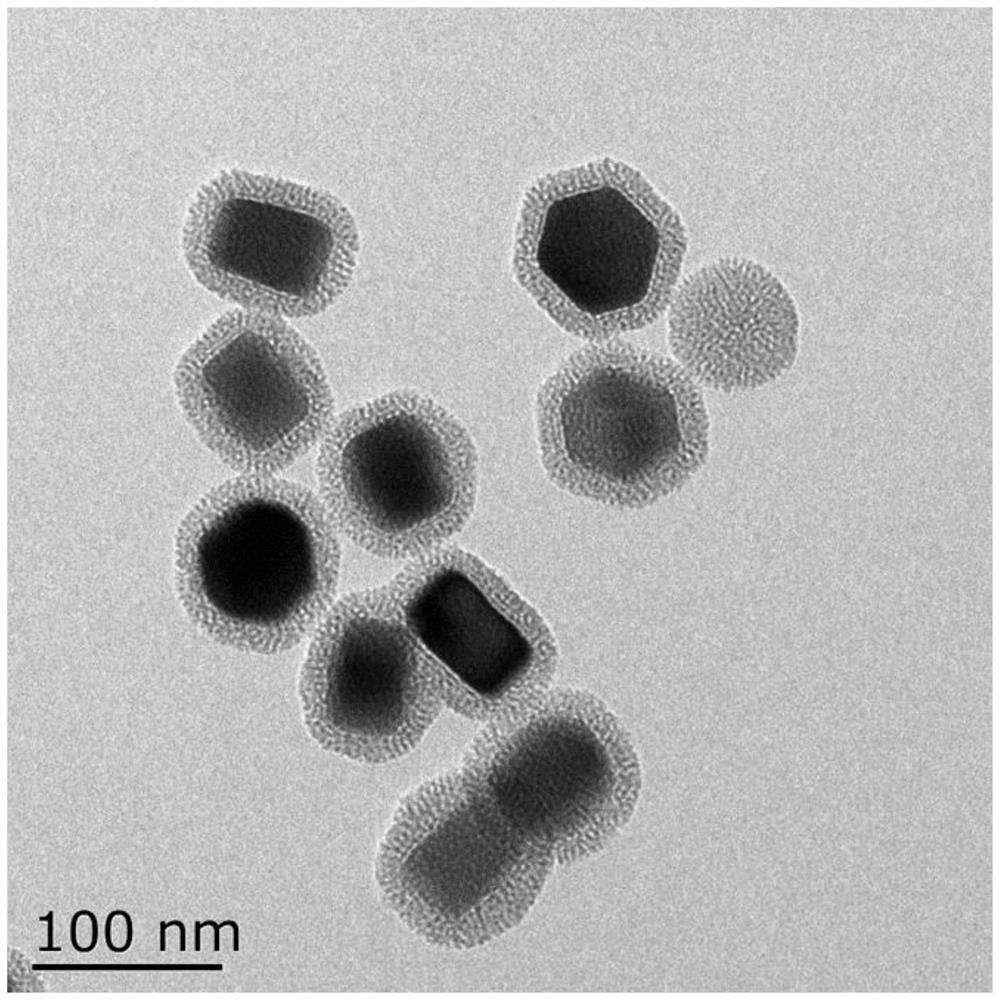

[0034] Step 1, preparation of up-conversion nanomaterials: Accurately weigh 0.2366g yttrium chloride hexahydrate, 0.0775g ytterbium chloride hexahydrate, 0.0076g erbium chloride hexahydrate, dissolve with 10mL of methanol ultrasonically for 10min, and transfer to a three-necked flask, Add 7mL of oleic acid and 15mL of octadecene; under the protection of argon, heat to 160°C for the first time, and cool to room temperature with magnetic stirring for 30min; add 0.6g of ammonium fluoride and 0.4g of hydrogen to the cooling liquid dropwise The methanol solution of sodium oxide was 10 mL, then the first water bath was reacted at 50 °C for 30 min, and the second water bath was reacted at 75 °C for 40 min, so that the methanol in the solution was completely volatilized; then, under argon protection, the second heating to 30...

Embodiment 2

[0040] The invention discloses a method for detecting furfural content in food based on an up-conversion and p-toluidine-specific system. The specific steps are:

[0041] Step 1, preparation of up-conversion nanomaterials: Accurately weigh 0.2366g yttrium chloride hexahydrate, 0.0775g ytterbium chloride hexahydrate, 0.0076g erbium chloride hexahydrate, dissolve with 10mL of methanol ultrasonically for 10min, and transfer to a three-necked flask, Add 7mL of oleic acid and 15mL of octadecene; under the protection of argon, heat to 150°C for the first time, and cool to room temperature with magnetic stirring for 30min; add 0.6g of ammonium fluoride and 0.4g of hydrogen to the cooling liquid dropwise The methanol solution of sodium oxide was 10 mL, then the first water bath was reacted at 40 °C for 30 min, and the second water bath was reacted at 70 °C for 40 min, so that the methanol in the solution was completely volatilized; then, under argon protection, the second heating to 29...

Embodiment 3

[0046] The invention discloses a method for detecting furfural content in food based on an up-conversion and p-toluidine-specific system. The specific steps are:

[0047] Step 1, preparation of up-conversion nanomaterials: Accurately weigh 0.2366g yttrium chloride hexahydrate, 0.0775g ytterbium chloride hexahydrate, 0.0076g erbium chloride hexahydrate, dissolve with 10mL of methanol ultrasonically for 10min, and transfer to a three-necked flask, Add 7mL of oleic acid and 15mL of octadecene; under the protection of argon, heat to 170°C for the first time, and cool to room temperature with magnetic stirring for 30min; add 0.6g of ammonium fluoride and 0.4g of hydrogen to the cooling liquid dropwise The methanol solution of sodium oxide was 10 mL, then the first water bath was reacted at 60 °C for 30 min, and the second water bath was reacted at 80 °C for 40 min, so that the methanol in the solution was completely volatilized; then, under argon protection, the second heating to 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com