Multi-target cooperative regulation and control method for electric arc additive manufacturing

An additive manufacturing and multi-objective technology, applied in the field of additive manufacturing, can solve the problems of restricting component forming efficiency and forming quality, difficult to coordinate control of component performance indicators, and reducing component mechanical properties, etc., to achieve low residual stress and deformation, Effect of high surface quality and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the data in the examples are all in a relatively simplified form and all use inaccurate ratios, and are only used to assist in explaining the implementation method of the present invention simply and clearly.

[0038] In this embodiment, 2319 aluminum alloy welding wire is used as the raw material, which is widely used in aerospace, rail transit, deep space exploration, ocean transportation and other fields due to its excellent specific strength, toughness, fatigue resistance, corrosion resistance and other properties.

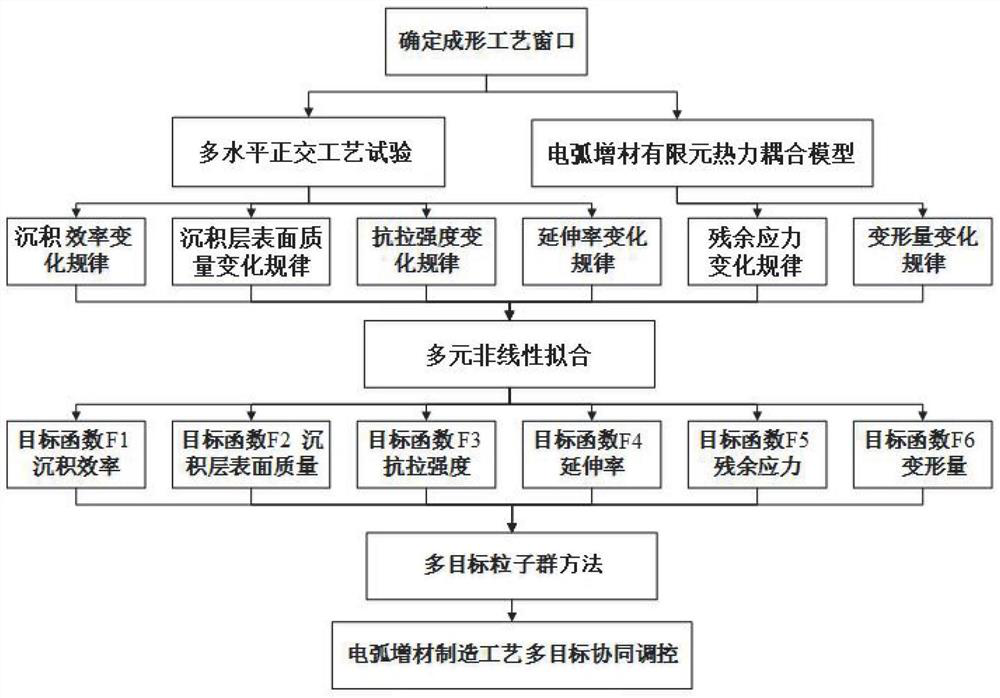

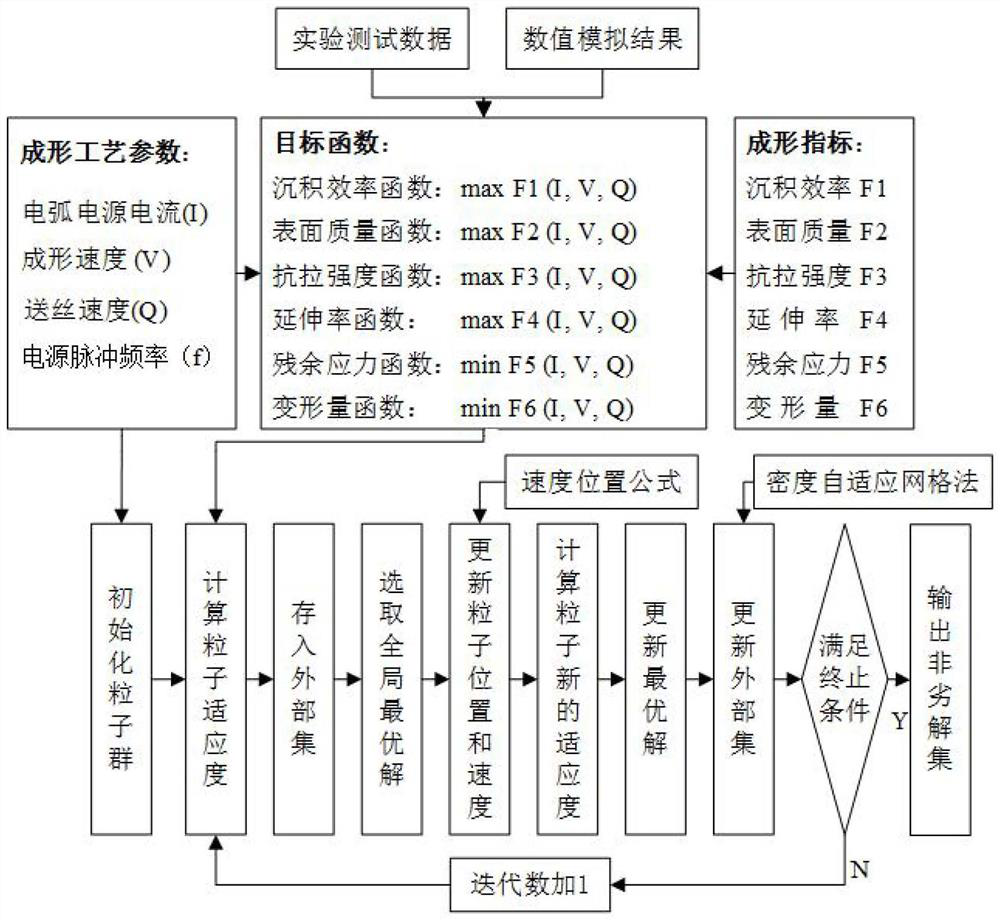

[0039] like figure 1 As shown, a multi-objective coordinated control method for arc additive manufacturing includes the following steps:

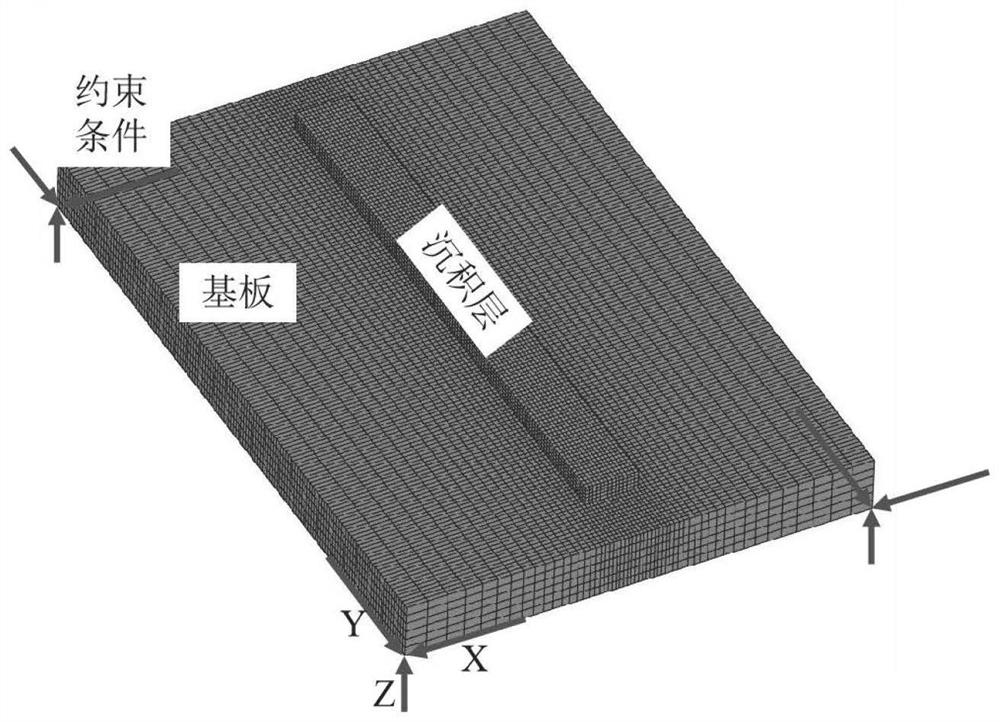

[0040] (1) Select three process parameters that are controllable, easy to adjust and have a significant impact on forming in the arc additive manufacturing process - arc power supply current (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com