Ceramic microbead gel material and preparation method thereof

A gel material and microbead technology, applied in alkali metal silicate coatings, coatings, climate change adaptation and other directions, can solve the problems of poor thermal insulation effect, complicated construction process, weak bonding and other problems, and achieve waterproofness. Excellent, environmentally friendly materials, the effect of reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

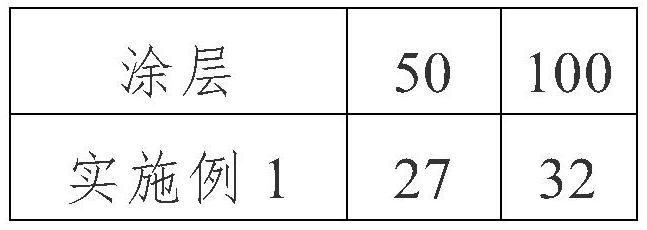

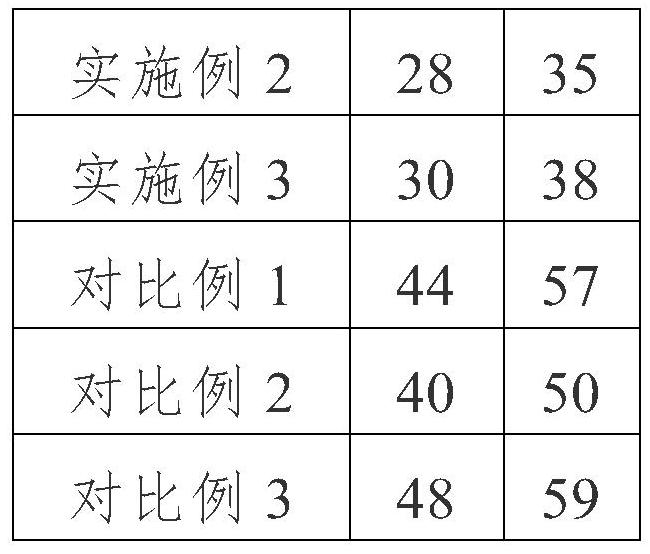

Embodiment 1

[0031] A preparation method of vacuum ceramic microbead gel material, which comprises the following steps:

[0032] The raw materials used are prepared by the following weights: 75 parts of vacuum ceramic microbeads, 8 parts of silicon carbide fibers, 1.3 parts of gelling agent (sodium hydroxymethyl cellulose), lithium silicate solution (modulus is 2.8, solid content is 22.5%) 18 parts, sodium silicate solution (modulus 3.5, solid content 32%) 32 parts, benzene-acrylic emulsion 0.5 parts, polyacrylamide 3 parts, cetyltrimethylammonium bromide 0.3 parts, 1.5 parts of Tween-80, 95 parts of water, the concentration of sodium hydroxide solution is 0.5mol / L, and the sulfuric acid solution is 5%.

[0033] S1. Dissolve cetyl trimethyl bromide in 90% water, stir evenly, add silicon carbide fiber, polyacrylamide, benzene-acrylic emulsion, stir and mix at 200 rpm for 30 min, add Tween-80 Continue to stir with vacuum ceramic beads for 15min;

[0034] S2. Mix the lithium silicate soluti...

Embodiment 2

[0038] A preparation method of vacuum ceramic microbead gel material, which comprises the following steps:

[0039] The raw materials used are prepared by the following weight: 66 parts of vacuum ceramic microbeads, 7 parts of silicon carbide fibers, 1.5 parts of gelling agent (carboxymethyl cellulose), lithium silicate solution (modulus is 2.8, solid content is 22.5 parts) %) 18 parts, sodium silicate solution (modulus 3.5, solid content 32%) 35 parts, benzene-acrylic emulsion 0.55 parts, polyacrylamide 3 parts, cetyltrimethylammonium bromide 0.4 parts, Tween -801.2 parts, 95 parts of water, the concentration of sodium hydroxide solution is 0.5mol / L, and the sulfuric acid solution is 5%.

[0040] S1. Dissolve cetyl trimethyl bromide in 85% water, stir evenly, add silicon carbide fiber, polyacrylamide, benzene-acrylic emulsion, stir and mix at 200 rpm for 30 minutes, add Tween-80 Continue to stir with vacuum ceramic beads for 15min;

[0041] S2. Mix the lithium silicate solu...

Embodiment 3

[0045] A preparation method of vacuum ceramic microbead gel material, which comprises the following steps:

[0046] The raw materials used are prepared according to the following weights: 73 parts of vacuum ceramic microbeads, 8.5 parts of silicon carbide fibers, 1.8 parts of gelling agent (polyvinyl alcohol), lithium silicate solution (modulus is 2.8, solid content is 22.5%) 19 parts, sodium silicate solution (modulus 3.5, solid content 32%) 35 parts, benzene-acrylic emulsion 0.5 parts, polyacrylamide 4.5 parts, cetyltrimethylammonium bromide 0.5 parts, Tween-802 98 parts of water, the concentration of sodium hydroxide solution is 0.5mol / L, and the concentration of sulfuric acid solution is 5%.

[0047] S1. Dissolve hexadecyl trimethyl bromide in 90% water, stir evenly, add silicon carbide fiber, polyacrylamide, benzene-acrylic emulsion, stir and mix at 300 rpm for 30 minutes, add Tween-80 Continue stirring with vacuum ceramic beads for 15min;

[0048] S2, mix the lithium s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com