Reflection-type nano ceramic-based heat insulation film and film preparation process thereof

A nano-ceramic, reflective technology, applied in the direction of reflection/signal coating, spraying device, coating, etc., can solve the problems of low efficiency, achieve low energy consumption, good chemical stability, and improve the effect of light scattering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

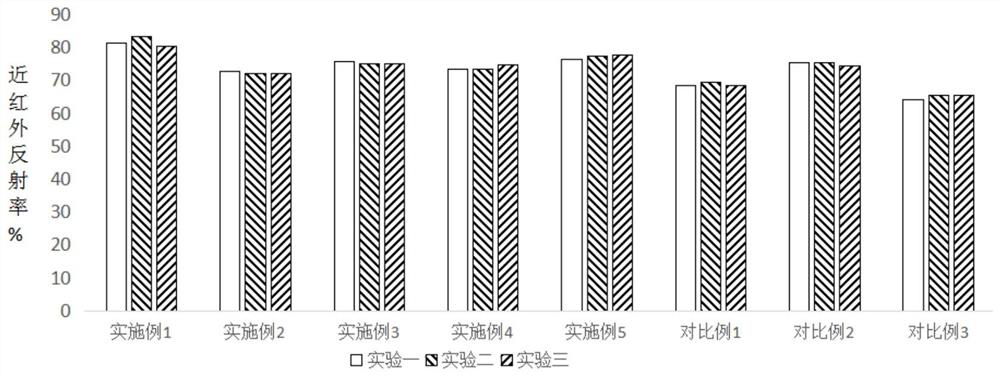

Examples

Embodiment 1

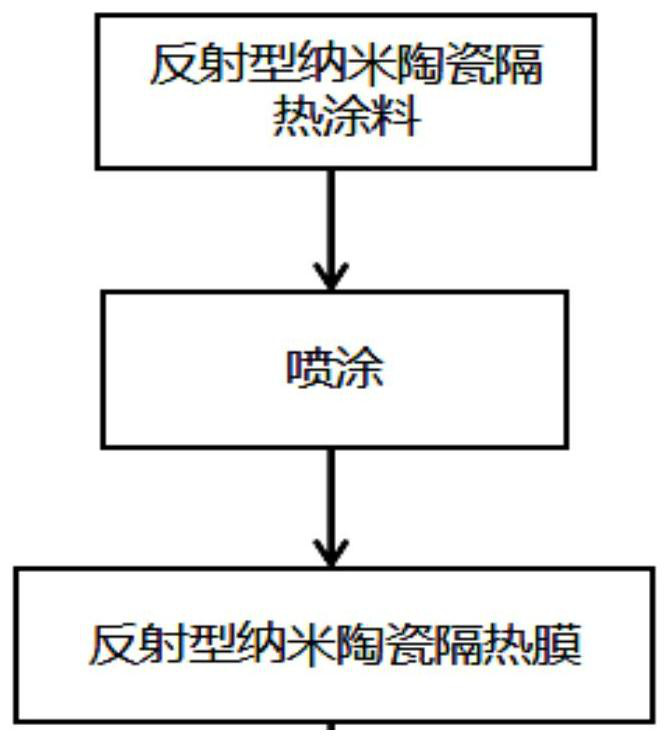

[0055] The present embodiment discloses a film-making process based on a reflective nano-ceramic thermal insulation film, which comprises the following steps:

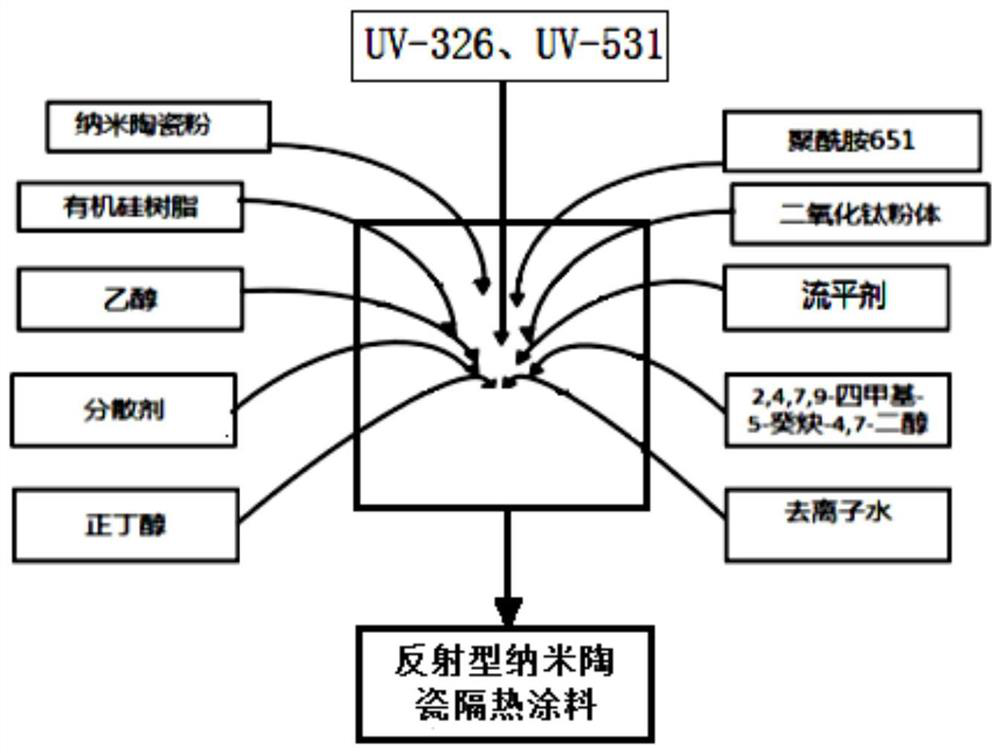

[0056] (1) Add silicone resin (CAS number: 67763-03-5), titanium dioxide powder, ethanol, deionized water, dispersant NNO, BYK-333 (leveling agent), 2,4,7 under magnetic stirring ,9-Tetramethyl-5-decyne-4,7-diol (defoamer), n-butanol, 2'-(2'-hydroxy-3'-tert-butyl-5'-methylbenzene base)-5-chlorobenzotriazole, 2-hydroxy-4-n-octyloxybenzophenone, nano-ceramic powder, polyamide 651 (curing agent) to obtain a reflective nano-ceramic heat-insulating coating; the total stirring time For 30min, the stirring speed is 500r / min. Among them, silicone resin (CAS number: 67763-03-5), titanium dioxide powder, ethanol, deionized water, dispersant NNO, BYK-333, 2,4,7,9-tetramethyl-5-decyne -4,7-Diol, n-butanol, 2'-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole, 2-hydroxy-4 -The mass ratio of n-octoxybenzophenone, n...

Embodiment 2

[0059] The present embodiment discloses a film-making process based on a reflective nano-ceramic thermal insulation film, which comprises the following steps:

[0060] (1) Add silicone resin (CAS number: 67763-03-5), titanium dioxide powder, ethanol, deionized water, dispersant NNO, BYK-333 (leveling agent), 2,4,7 under magnetic stirring ,9-Tetramethyl-5-decyne-4,7-diol (defoamer), n-butanol, 2'-(2'-hydroxy-3'-tert-butyl-5'-methylbenzene base)-5-chlorobenzotriazole, 2-hydroxy-4-n-octyloxybenzophenone, nano-ceramic powder, polyamide 651 (curing agent) to obtain a reflective nano-ceramic heat-insulating coating; the total stirring time For 60min, the stirring speed is 500r / min. Among them, silicone resin (CAS number: 67763-03-5), titanium dioxide powder, ethanol, deionized water, dispersant NNO, BYK-333, 2,4,7,9-tetramethyl-5-decyne -4,7-Diol, n-butanol, 2'-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole, 2-hydroxy-4 -The mass ratio of n-octoxybenzophenone, n...

Embodiment 3

[0063] The present embodiment discloses a film-making process based on a reflective nano-ceramic thermal insulation film, which comprises the following steps:

[0064] (1) Add silicone resin (CAS number: 67763-03-5), titanium dioxide powder, ethanol, deionized water, dispersant NNO, BYK-333 (leveling agent), 2,4,7 under magnetic stirring ,9-Tetramethyl-5-decyne-4,7-diol (defoamer), n-butanol, 2'-(2'-hydroxy-3'-tert-butyl-5'-methylbenzene base)-5-chlorobenzotriazole, 2-hydroxy-4-n-octyloxybenzophenone, nano-ceramic powder, polyamide 651 (curing agent) to obtain a reflective nano-ceramic heat-insulating coating; the total stirring time It is 45min, and the stirring speed is 500r / min. Among them, silicone resin (CAS number: 67763-03-5), titanium dioxide powder, ethanol, deionized water, dispersant NNO, BYK-333, 2,4,7,9-tetramethyl-5-decyne -4,7-Diol, n-butanol, 2'-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole, 2-hydroxy-4 -The mass ratio of n-octyloxybenzoph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com