Enrichment method of waste silicon dioxide carrier noble metal catalyst

A precious metal catalyst and waste silicon dioxide technology, applied in the direction of improving process efficiency, etc., can solve the problems of difficult filtration and washing, easy corrosion, and large tail gas pollution, so as to avoid dispersion loss, wide application range, and good enrichment effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

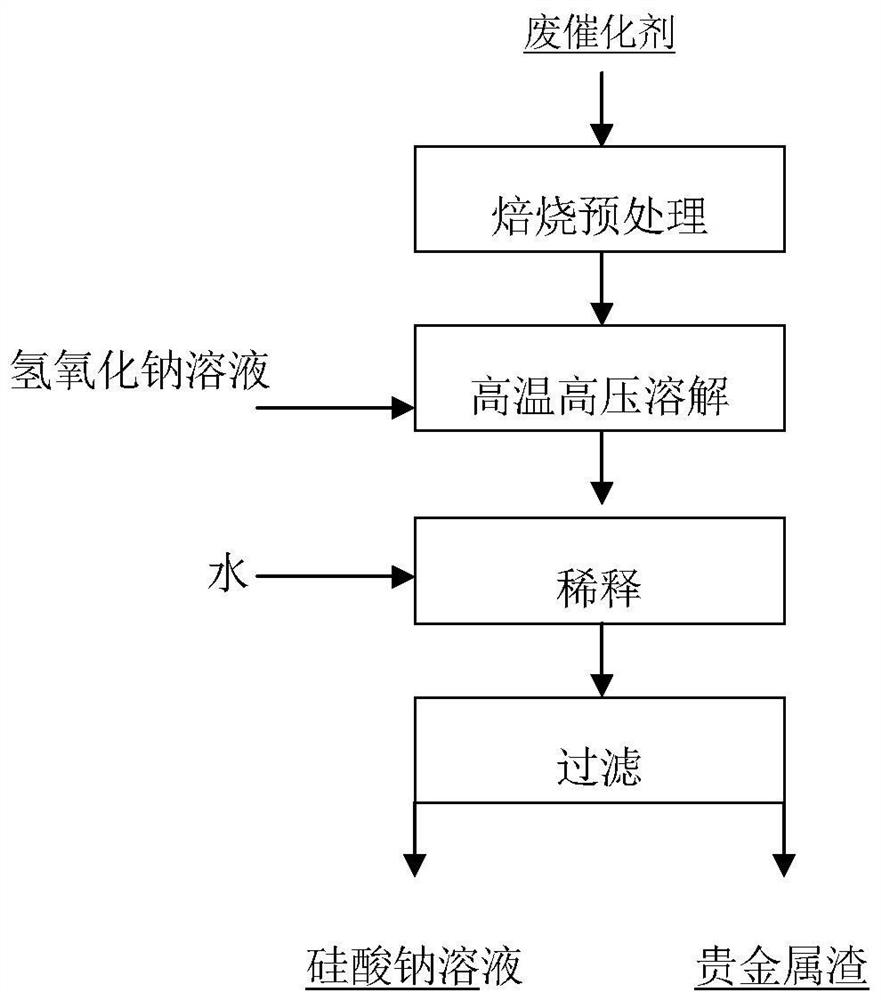

[0026] like figure 1 shown, a waste Pd-Au / SiO 2 A palladium enrichment method for a catalyst, including:

[0027] (1) The waste Pd-Au / SiO 2 The catalysts (Pd 3062g / t, Au 5925g / t) were calcined at 600°C until the carbon content was less than 1%;

[0028] (2) get 200g of spent catalyst and 600mL of sodium hydroxide solution with mass concentration of 50% and add it to a 1L high-pressure reaction kettle, fill the reaction kettle with nitrogen to discharge the air therein, cover with a sealing cover, start stirring and heating device, heated to 220 ℃, constant temperature reaction 3h;

[0029] (3) cooling down to 80 ° C, pouring out the feed liquid and adding 600 mL of water to dilute, filtering, washing, until there is no sodium silicate in the washing liquid, to obtain palladium, gold enriched slag;

[0030] (4) Palladium and gold were not detected in the filtrate; the enriched residue weighed 5.6 g after drying, and palladium and gold were enriched by 35.7 times.

Embodiment 2

[0032] A platinum enrichment method for a waste silica gel supported platinum catalyst, comprising:

[0033] (1) calcining the waste silica gel supported platinum catalyst (Pt 1.03%) at 600° C. until the carbon content is less than 1%;

[0034] (2) get 200g of spent catalyst and 600mL of sodium hydroxide solution with mass concentration of 50% and add it to a 1L high-pressure reaction kettle, fill the reaction kettle with nitrogen to discharge the air therein, cover with a sealing cover, start stirring and heating device, heated to 200 ℃, constant temperature reaction 2h;

[0035] (3) cooling down to 80° C., pouring out the feed solution and adding 600 mL of water to dilute, filtering and washing until there is no sodium silicate in the washing solution to obtain platinum-enriched slag;

[0036] (4) No platinum was detected in the filtrate; the platinum-enriched slag weighed 4.4 g after drying, and the platinum was enriched by 45.5 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com