PIN multipurpose diode with GaN/BGaN/GaN structure and preparation method thereof

A multi-purpose, diode technology, used in semiconductor/solid-state device manufacturing, coating, gaseous chemical plating, etc. The effect of reducing parasitic capacitance, reducing the concentration of two-dimensional electron gas, and efficiently modulating carrier lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

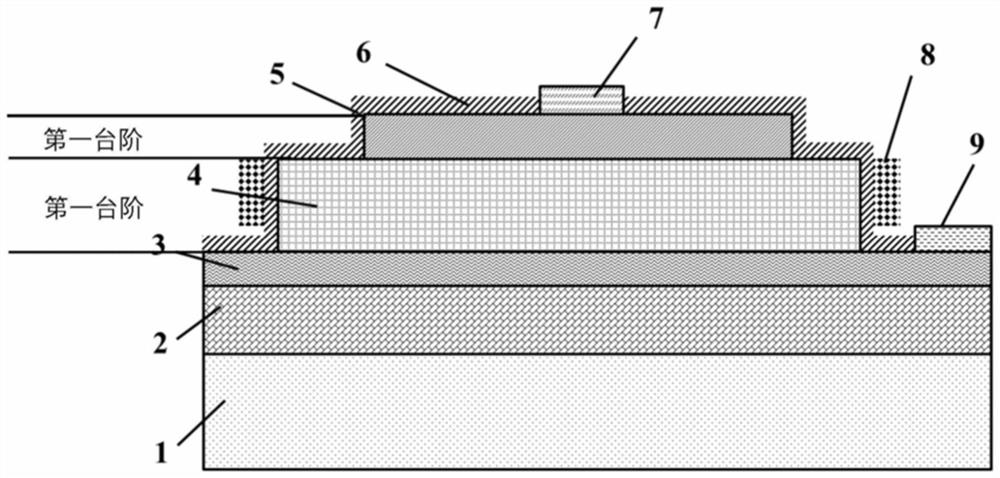

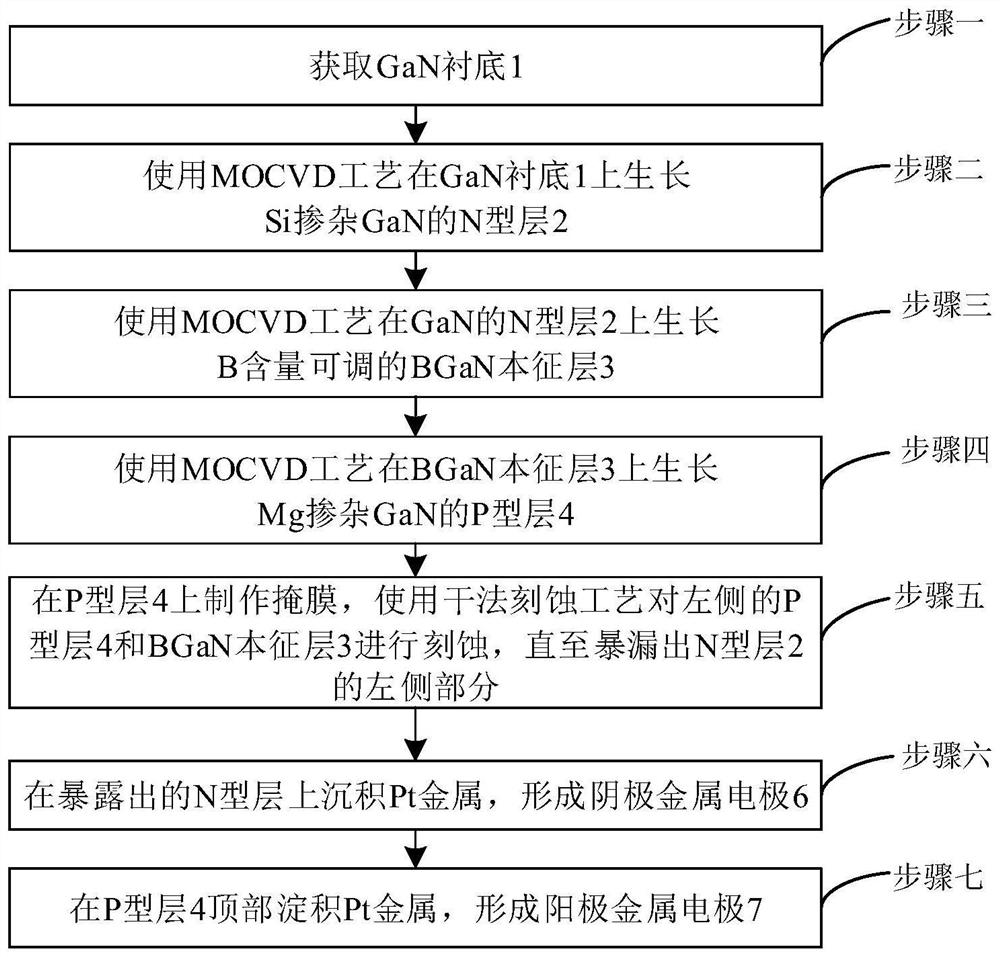

[0026] like figure 2 As shown, a preparation method of a PIN multi-purpose diode with a GaN / BGaN / GaN structure provided by the present invention includes:

[0027] Step 1: Obtain GaN substrate 1;

[0028] Step 2: growing an N-type layer 2 of Si-doped GaN on the GaN substrate 1 using an MOCVD process;

[0029] Among them, the thickness of the N-type layer 2 is 50-300 nm; the process conditions for growing the N-type layer of Si-doped GaN with a thickness of 200 nm are: temperature 1000 ° C, pressure 300 Torr, gallium source flow 100 sccm, Si source flow 50 sccm, ammonia flow 20000 sccm , the hydrogen flow rate is 40000sccm.

[0030] Step 3: growing a BGaN intrinsic layer 3 with adjustable B content on the N-type layer 2 of GaN using MOCVD process;

[0031] Wherein, the content of B is adjusted in the range of 10%-30%, and the thickness of the BGaN intrinsic layer 3 is 30-200 nm. The process conditions for the grown BGaN intrinsic layer 3 are: temperature 1000° C., pressure...

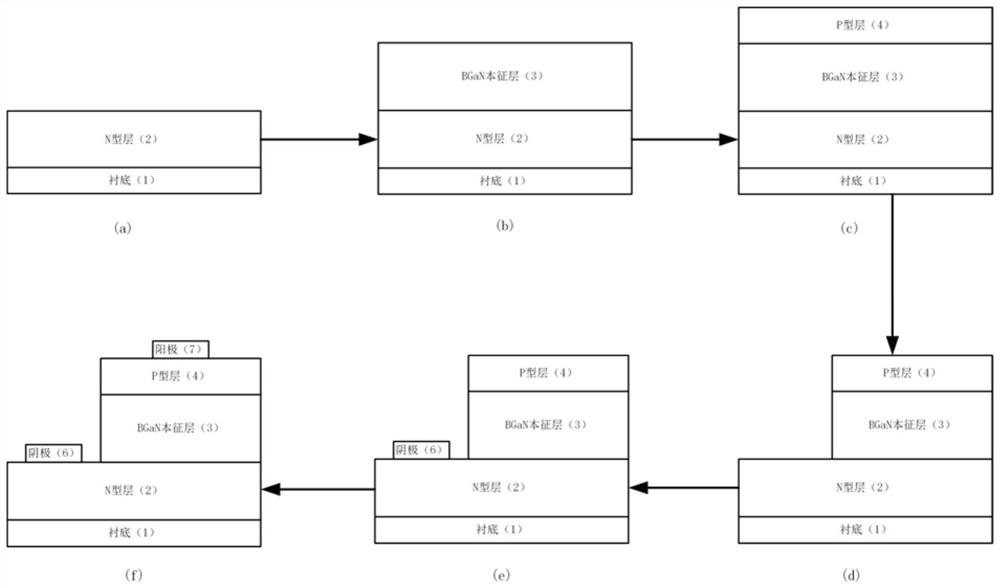

Embodiment 1

[0041] step 1, as image 3 As shown in the neutron diagram a, 200nm Si-doped GaN was grown on a GaN substrate by MOCVD process. The process conditions are: temperature 1000℃, pressure 300Torr, gallium source flow rate 100sccm, Si source flow rate 50sccm, ammonia gas flow rate 20000sccm, hydrogen gas flow rate Flow 40000sccm;

[0042] step 2, as image 3 As shown in neutron diagram b, a 100nm BGaN intrinsic layer was grown on the GaN N-type layer using MOCVD process, where the B content was 15%, and the process conditions were: temperature 1000°C, pressure 300Torr, gallium source flow 80sccm, B source flow 30sccm, ammonia flow 20000sccm, hydrogen flow 40000sccm

[0043] step 3, as image 3 As shown in neutron diagram c, 200nm Mg-doped GaN was grown on the BGaN intrinsic layer by MOCVD process. The process conditions were: temperature 1000℃, pressure 300Torr, gallium source flow rate 100sccm, Mg source flow rate 500sccm, ammonia gas flow rate 20000sccm, Hydrogen flow 40000sc...

Embodiment 2

[0048] step 1, as image 3 As shown in the neutron diagram a, 200nm Si-doped GaN was grown on a GaN substrate by MOCVD process. The process conditions are: temperature 1000℃, pressure 300Torr, gallium source flow rate 100sccm, Si source flow rate 50sccm, ammonia gas flow rate 20000sccm, hydrogen gas flow rate Flow 40000sccm;

[0049] step 2, as image 3 As shown in the neutron diagram b, a 100nm BGaN intrinsic layer was grown on the GaN N-type layer using the MOCVD process, where the B content was 20%, and the process conditions were: temperature 1000 ° C, pressure 300 Torr, gallium source flow 80sccm, B source flow 40sccm, ammonia flow 20000sccm, hydrogen flow 40000sccm

[0050] step 3, as image 3 As shown in neutron diagram c, 200nm Mg-doped GaN was grown on the BGaN intrinsic layer by MOCVD process. The process conditions were: temperature 1000℃, pressure 300Torr, gallium source flow rate 100sccm, Mg source flow rate 500sccm, ammonia gas flow rate 20000sccm, Hydrogen f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com