High-strength concrete for CL thermal insulation integration

A concrete and high-strength technology, applied in the field of concrete, can solve the problems of exposed insulation boards, failure to meet the design strength requirements, and the concrete strength of the outer shear wall cannot meet the requirements, so as to meet high-strength requirements, improve strength, and be economical benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation of the composite fly ash adopts hydrothermal treatment, and the iron-nickel nanorods are anchored on the surface of the fly ash, and then through the hydrothermal growth, a nanocrystalline layer is constructed on the surface of the fly ash, thereby obtaining the composite fly ash. The operation is as follows:

[0028] The nickel salt and the iron salt are mixed and dissolved in a mixed solvent of ethylene glycol and ultrapure water, anhydrous oxalic acid is added, the fly ash is mixed as a carrier in an autoclave to carry out a hydrothermal reaction, and the obtained product is dispersed in distilled water, A dispersion is formed, wherein the temperature of the hydrothermal reaction is 150-160°C, and the holding time is 12-15h, wherein the nickel salt is nickel chloride hexahydrate, the iron salt is anhydrous ferrous chloride, and the fly ash is ordinary grade II powder Coal ash, fineness ≤25.0%, water requirement ≤105%, loss on ignition ≤8.0%;

[0029]...

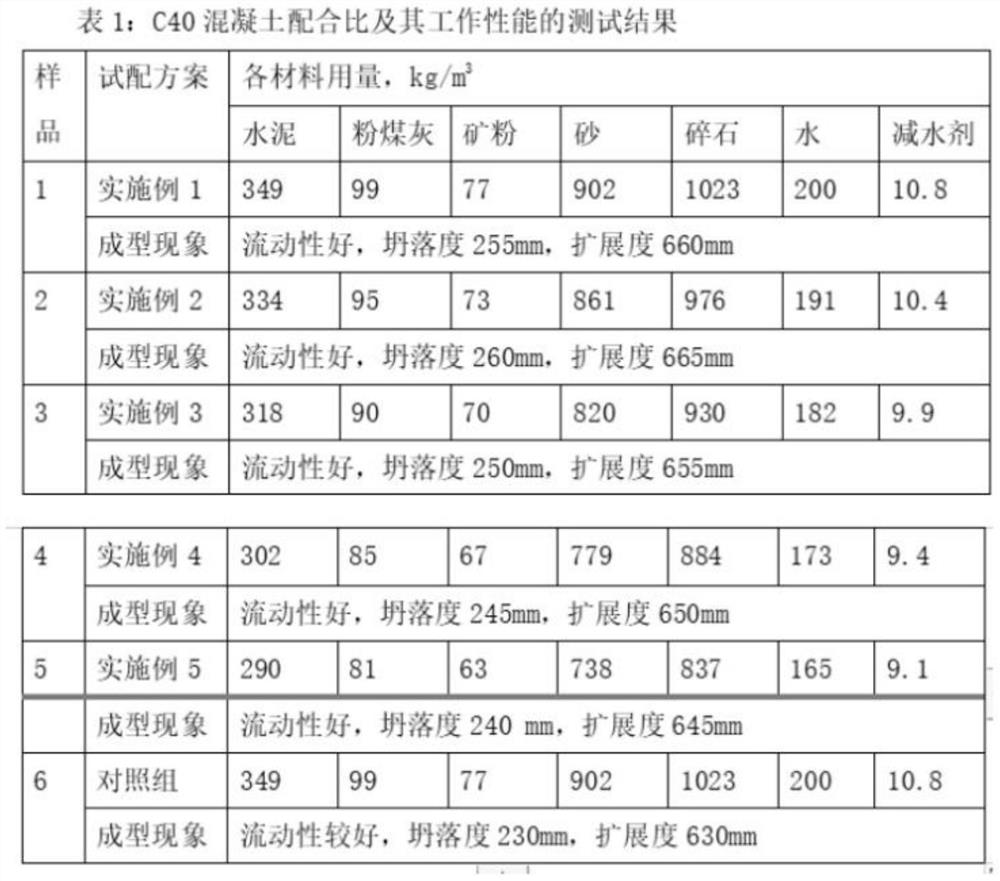

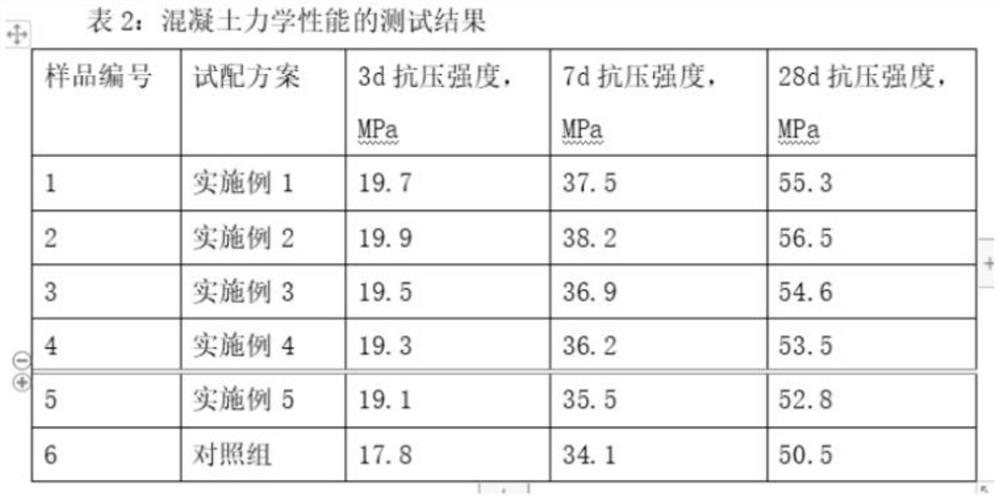

Embodiment 1

[0031] A high-strength concrete for the integration of CL thermal insulation, according to the single square (m 3 ) consumption meter, the consumption of each component of this concrete is as follows: cement 349kg, mineral powder 77kg, composite fly ash 99kg, natural sand 902kg, natural stone crushed stone 1023kg, water reducing agent 10.8kg, water 200kg, wherein, particle diameter 5-10mm The crushed stone is 310kg of the total amount of crushed stone, and the crushed stone with a particle size of 10-30mm is 713kg of the total amount of crushed stone.

[0032]After the materials are prepared, the above components are mixed, and the mixture is stirred for 2 minutes by a forced mixer in the Forbidden City to obtain the high-strength concrete described in the present invention.

[0033] The construction method of the high-strength concrete described in the present invention, its technological operation is as follows: when the concrete is pumped, the concrete should be unloaded on...

Embodiment 2

[0035] A high-strength concrete for the integration of CL thermal insulation, according to the single square (m 3 ) consumption meter, the consumption of each component of this concrete is as follows: cement 334kg, mineral powder 73kg, composite fly ash 95kg, natural sand 861kg, natural stone crushed stone 976kg, water reducing agent 10.4kg, water 191kg, wherein, particle diameter 5-10mm The crushed stone is 342kg of the total amount of crushed stone, and the crushed stone with a particle size of 10-30mm is 634kg of the total amount of crushed stone.

[0036] After the materials are prepared, the above components are mixed, and the mixture is stirred for 2 minutes by a forced mixer in the Forbidden City to obtain the high-strength concrete described in the present invention.

[0037] The construction method of the high-strength concrete described in the present invention, its technological operation is as follows: when using pumping concrete, the concrete should be unloaded on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com