Anti-swelling clay stabilizer and preparation method thereof

A clay stabilizer and anti-expansion technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of limited application range and poor temperature resistance, and achieve simple synthesis and preparation process, high anti-expansion rate, The effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

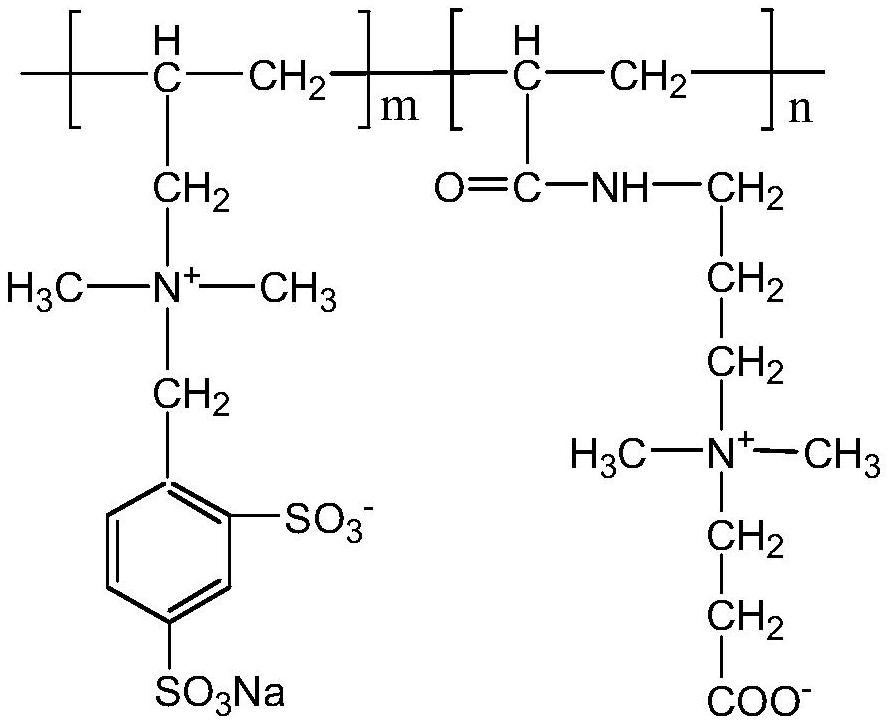

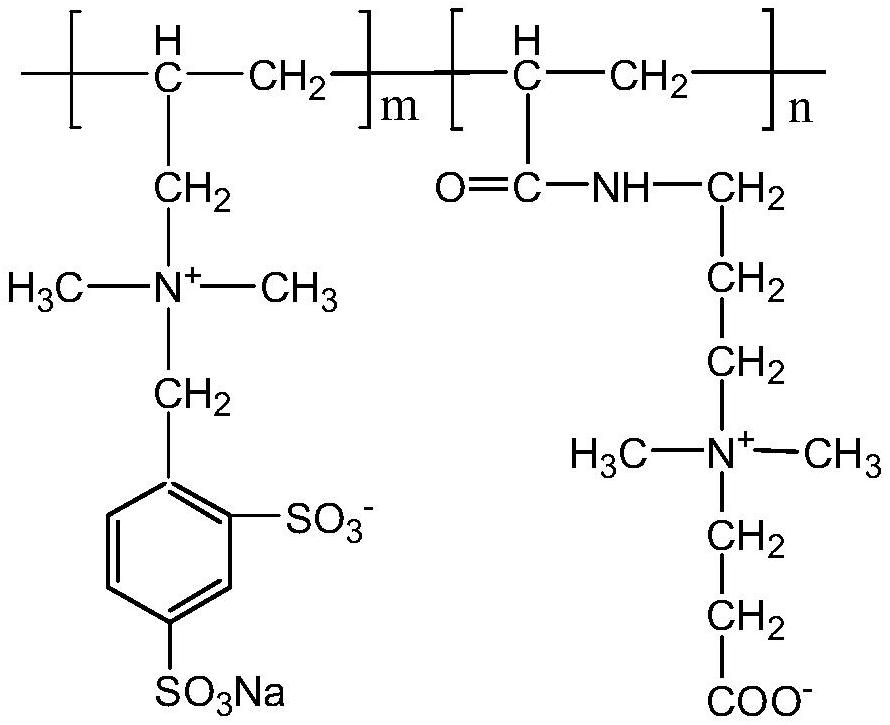

Image

Examples

Embodiment 1

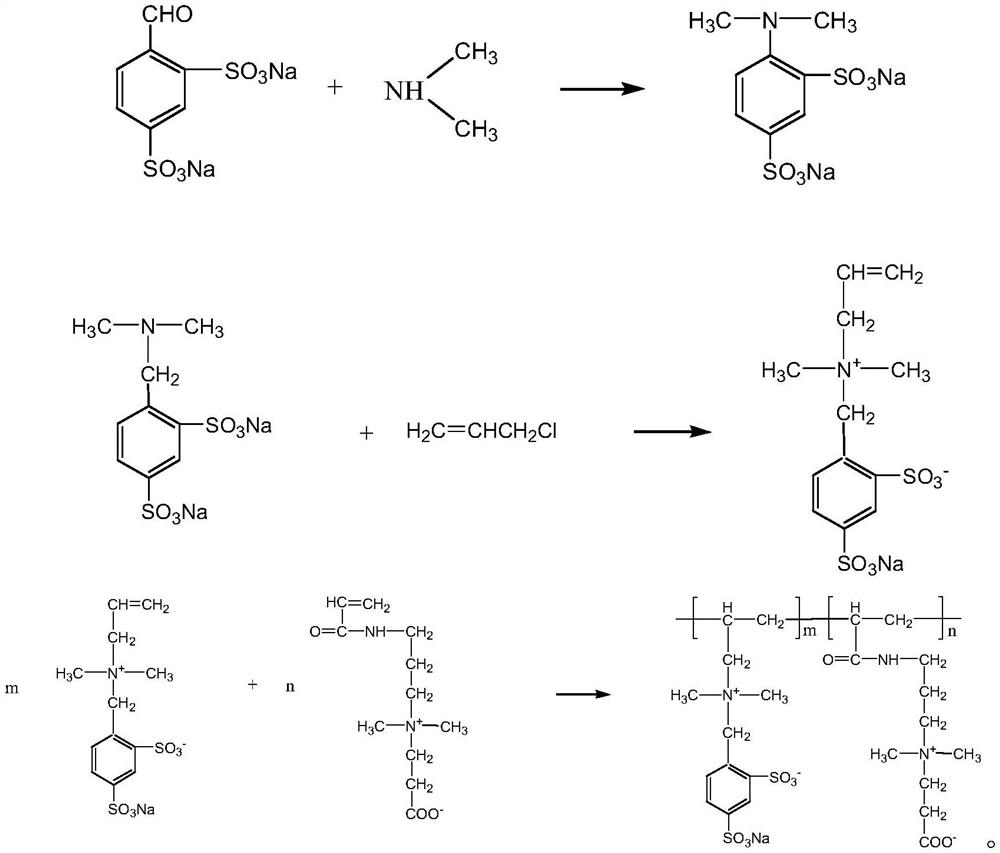

[0038] (1) successively add 0.02mol of sodium benzaldehyde-2,4-disulfonate, 0.02mol of sodium cyanoborohydride, 0.02mol of dimethylamine, 31g of methanol in the reactor, heat under reflux for 4h, evaporate to dryness;

[0039] (2) Add 0.02mol of allyl chloride, 0.31g of sodium sulfite, 0.62g of copper chloride and 62g of ethanol to the above-mentioned reactor, stir and heat under reflux for 12h, filter, and distill the filtrate under reduced pressure to obtain a viscous intermediate, add ethyl acetate Ester 31g, heated to dissolve, filtered, the filtrate was cooled to below 10 ℃, and crystals were precipitated;

[0040] (3) The above crystals, 0.004mol of 3-[(3-acrylamidopropyl)dimethylammonium] propionate, 37.2g of water, TX-100.31g and MS-10.31g were added to the reactor, and the mixture was stirred evenly. Continue to stir, at the same time add 1.24g of 10% sodium persulfate solution dropwise, after the dropwise addition, heat up to 50°C, keep the temperature for 2h, add 0....

Embodiment 2

[0043](1) in the reactor, add 0.02mol of sodium benzaldehyde-2,4-disulfonate, 0.026mol of sodium cyanoborohydride, 0.026mol of dimethylamine, 62g of methanol successively, heated to reflux for 8h, evaporated to dryness;

[0044] (2) Add allyl chloride 0.026mol, sodium sulfite 0.62g, copper chloride 1.24g and ethanol 124g in the above-mentioned reactor, stir and heat under reflux for 24h, filter, and distill the filtrate under reduced pressure to obtain a viscous intermediate, add ethyl acetate Ester 49.6g, heated to dissolve, filtered, the filtrate was cooled to below 10°C, and crystals were precipitated;

[0045] (3) The above crystals, 0.01mol of 3-[(3-acrylamidopropyl)dimethylammonium]propionate, 62g of water, TX-100.62g, and 10.62g of MS-10.62g were added to the reactor, stirred evenly, and continued Stir, at the same time, add 3.1 g of 10% sodium persulfate solution dropwise. After the dropwise addition, the temperature is raised to 52 °C, and the temperature is kept for ...

Embodiment 3

[0048] (1) successively add 0.02mol of sodium benzaldehyde-2,4-disulfonate, 0.022mol of sodium cyanoborohydride, 0.022mol of dimethylamine, 38g of methanol in the reactor, heat under reflux for 6h, evaporate to dryness;

[0049] (2) 0.022mol of allyl chloride, 0.44g of sodium sulfite, 0.88g of copper chloride and 89g of ethanol were added to the above-mentioned reactor, stirred and heated to reflux for 16h, filtered, and the filtrate was distilled under reduced pressure to obtain a viscous intermediate, and ethyl acetate was added. Ester 34g, heated to dissolve, filtered, the filtrate was cooled to below 10°C, and crystals were precipitated;

[0050] (3) The above crystal, 0.006mol of 3-[(3-acrylamidopropyl)dimethylammonium]propionate, 42g of water, TX-100.44g, and 10.45g of MS-10.45g were added to the reactor, stirred evenly, and continued While stirring, 1.81g of 10% potassium persulfate solution was added dropwise at the same time. After the addition was completed, the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com