Modified glucan nano-microsphere composite dressing and preparation method thereof

A technology of nano-microspheres and dextran, which is applied in the field of medical materials, can solve the problems of difficult growth factors, achieve the effect of promoting healing, simple operation process, and preventing secondary infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

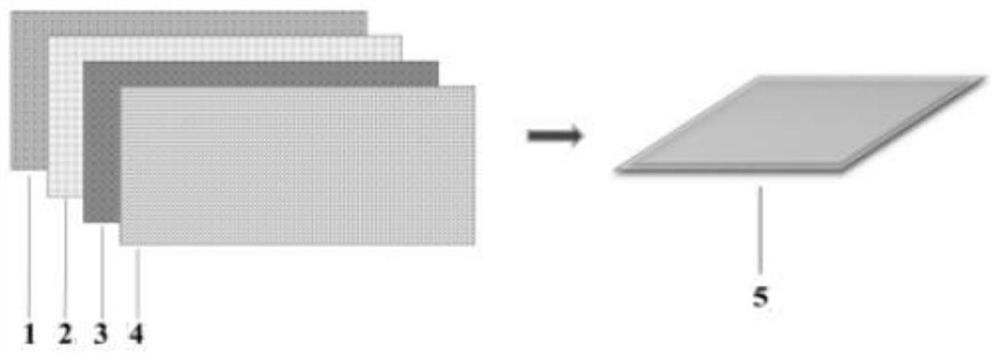

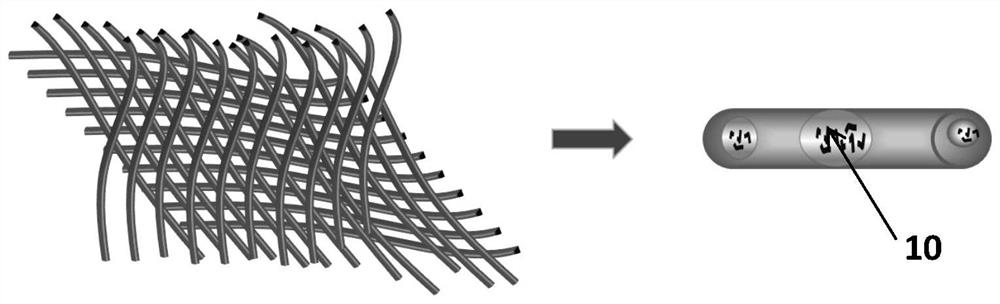

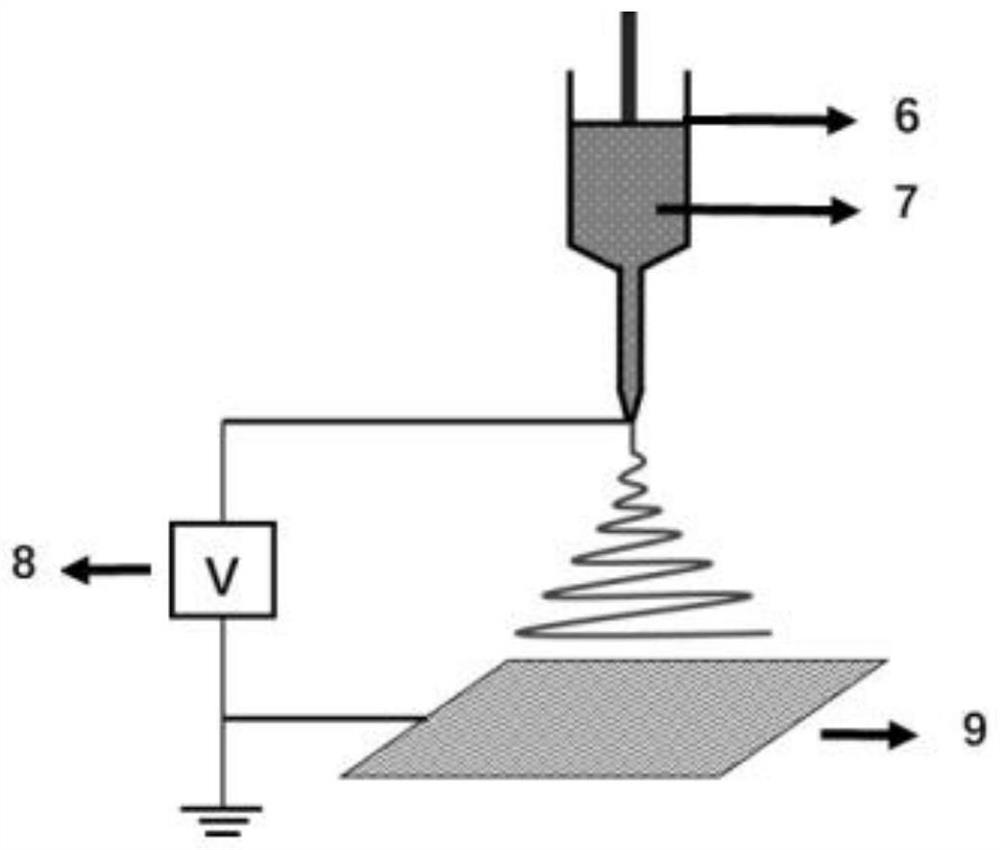

[0051] First, this embodiment provides a modified glucan nano -nano -ball composite dressing 5, which includes active layer 1. Waterproof layer 2. Berbal layer 3 and protective layer 4. Among them The waterproof layer 2 and the bacterial layer 3 are the middle layer, and the protective layer 4 is the outermost layer; the active layer 1 is specifically scattered inside the fiber to modify the sodium alginate-polyvinyl compound fibrous membrane, polyethylene glycol, Modified glucan nano -micro -balls are specifically for the glucose nano -nano -balls with growth factor; waterproof layer 2 is an ordinary polypropylene non -woven fabric, which is mainly to isolate the active layer of absorbing exudate 1 and the bacterial layer 3 , Prevent the bacterial layer 3 in dyeing, and play a certain protective role in the bacterial layer 3; the bacterial layer 3 is a melting spray non -woven non -woven non -woven non -woven non -woven non -woven of polypropylene resin that uses economic practic...

Embodiment 2

[0064] First, this embodiment provides a preparation method for modified glycogen nano -ball composite dressing. The steps are basically the same as the preparation method provided by Example 1. The difference is:

[0065] Step (1), growth factor: glucan: PEG6000 = 1: 800: 1000 (w / w / w);

[0066] Step (2), configure it to 8 % PVA aquatic solution;

[0067] Step (3), configure to be configured to 1.5 % sodium alginate solution;

[0068] Step (4), the mixed ratio of PVA aquatic solution and sodium algina solution is 1.5: 2;

[0069] In the step (5), the amount of modified glucan nano-nano-golf is 10 % of the mass score of sodium algina-polyvinyl alcohol solution;

[0070] Step (7), CACL 2 The concentration of aquatic ethanol solution is 3 %;

[0071] In the step (8), the cross -linking time is 4h.

[0072] Second, this embodiment provides a modified glucan nano -ball composite dressing, which is obtained by the preparation method provided by this embodiment.

Embodiment 3

[0074] First, this embodiment provides a preparation method for modified glycogen nano -ball composite dressing. The steps are basically the same as the preparation method provided by Example 1. The difference is:

[0075] Step (1), growth factor: glucan: PEG6000 = 1: 800: 1000 (w / w / w);

[0076] Step (2), configure to be configured to 13 % PVA aquatic solution;

[0077] Step (3), configure to be configured to 1.2 % sodium alginate solution;

[0078] Step (4), the mixed ratio of PVA aquatic solution and sodium algina solution is 1.5: 1;

[0079] In the step (5), the amount of modified glucan nano-nano-golf is 10 % of the mass score of sodium algina-polyvinyl alcohol solution;

[0080] Step (7), CACL 2 The concentration of aquatic ethanol solution is 5 %;

[0081] In the step (8), the cross -linking time is 1h.

[0082] Second, this embodiment provides a modified glucan nano -ball composite dressing, which is obtained by the preparation method provided by this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com