Method for in-situ preparation of titanium dioxide/cellulose nano-composite microspheres

A technology of cellulose microspheres and titanium dioxide, applied in chemical instruments and methods, oxidized water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve difficult titanium dioxide/cellulose composite microspheres, reduce active sites , Reduce photocatalytic activity and other issues, achieve the effect of easy to master the preparation process, excellent photocatalytic performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

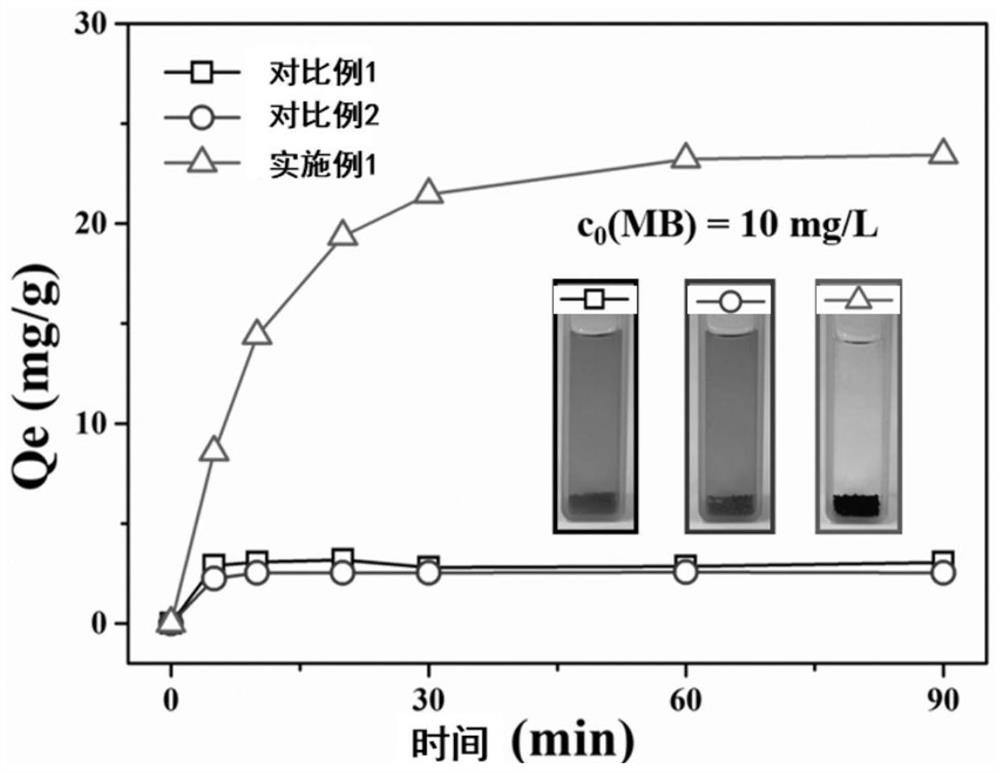

Embodiment 1

[0036] A method for in-situ preparation of titanium dioxide / cellulose nanocomposite microspheres, the raw materials and reagents used are as follows:

[0037] Raw materials: virgin cellulose (cotton linters, degree of polymerization 500), n-butyl titanate Reagents: lithium hydroxide, urea, triethanolamine, Span 80, liquid paraffin, deionized water The preparation method adopts the following steps:

[0038] (1) Preparation of n-butyl titanate pre-hydrolysis solution: at room temperature, n-butyl titanate and triethanolamine were mixed in a molar ratio of 1:2, and deionized water was added dropwise to the mixture to obtain the final concentration of n-butyl titanate. Be 1.25mol / L, reaction obtains pre-hydrolyzate;

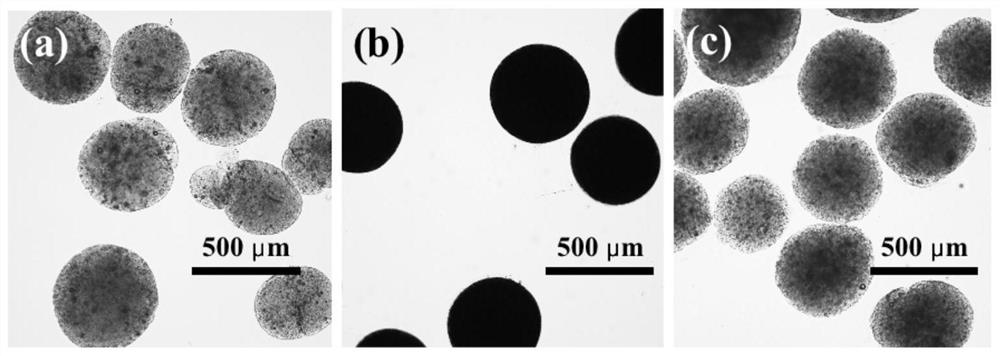

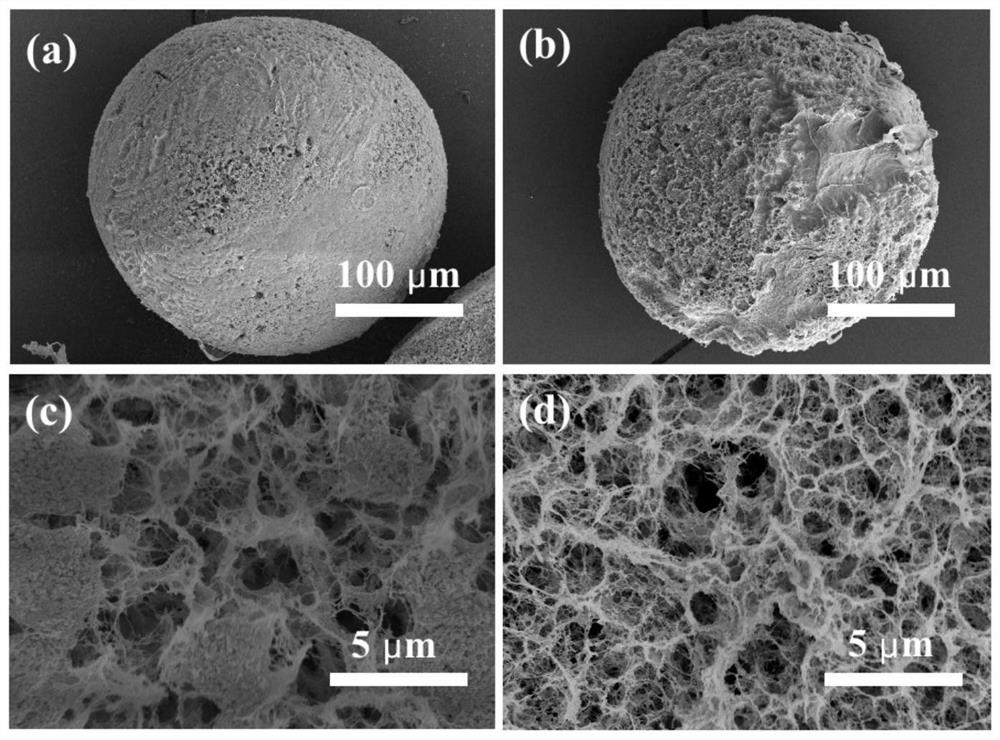

[0039](2) Preparation of gel prefabricated solution: Lithium hydroxide and urea are dissolved in deionized water, and then frozen. The dried 2.57g cellulose was added to the frozen 100g mixed solvent, and 5.0 mL of the n-butyl titanate prehydrolyzate obtained in ste...

Embodiment 2

[0041] A method for modifying titanium dioxide / cellulose nanocomposite microspheres prepared in situ, the raw materials and reagents used are as follows:

[0042] Raw material: Microspheres prepared in Example 1

[0043] Reagents: Rhodamine B, hydrogen peroxide, deionized water

[0044] The preparation method adopts the following steps:

[0045] (1) Preparation of Rhodamine B solution: Weigh a certain amount of Rhodamine B and dissolve it in deionized water, and set the volume for use;

[0046] (2) Rhodamine B degradation intermediate modified microspheres: The microspheres in Example 1 were added to the Rhodamine B solution, and a certain amount of hydrogen peroxide was added to degrade Rhodamine B under light conditions. When the solution was colorless and transparent, the modified microspheres were obtained by sedimentation separation.

Embodiment 3~20

[0047] Embodiments 3 to 20 are shown in Table 1:

[0048] Table 1. Preparation conditions of Examples 3-20

[0049]

[0050] Table 2 Example 3-20 Size, Titanium Dioxide Load, Adsorption, Degradation Performance Comparison Table

[0051]

[0052]

[0053] *Degradation time is 70 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com