Preparation method of amorphous aluminum hydroxide

An aluminum hydroxide and amorphous technology, applied in the fields of alumina/hydroxide preparation, alkali metal aluminate/alumina/aluminum hydroxide preparation, chemical instruments and methods, etc., can solve the problem of high degree of fine operation, Low product yield, high sodium content and other problems, to achieve the effect of simple conversion process, high activity, and guaranteed purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of amorphous aluminum hydroxide, comprising the following steps:

[0028] (1) Under the condition that the stirring speed is not less than 800r / min, add a certain concentration of aluminum salt solution to the solution containing sodium aluminate at a certain speed, and control the temperature of the reaction system to be not higher than 70 ℃ during the reaction process, At the same time, the pH meter was used to track the reaction, and the pH of the reaction system was controlled between 4-6 to obtain a white slurry; min; the temperature of the reaction system can be 45°C, 50°C, 60°C, 65°C, or 70°C; the pH of the reaction system can be 4, 4.5, 5, 5.5 or 6;

[0029] (2) aging the slurry obtained in step (1), and performing solid-liquid separation and drying on the aged slurry to obtain amorphous aluminum hydroxide.

[0030] Specifically, the aluminum salt in the step (1) is one or more of aluminum sulfate, aluminum chloride, or aluminum nitrate, su...

Embodiment 1

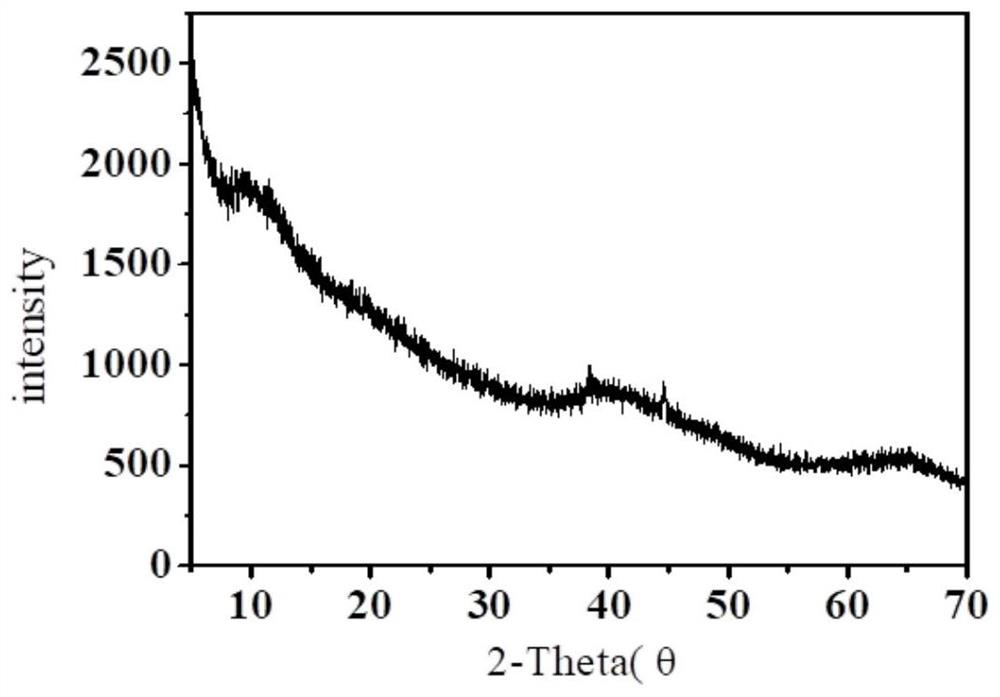

[0037] Take the sodium aluminate refined liquid, an intermediate material of the alumina sintering method, cool down to 30 °C, and pour an appropriate amount into a beaker for later use. Use aluminum sulfate with an alumina content of 4.5% as the aluminum salt, and the temperature of the aluminum sulfate solution is 30 ° C, start stirring, and the stirring speed is 1250 r / min. Use a peristaltic pump to drop aluminum sulfate into the sodium aluminate solution, and the end point PH is controlled at 4.5 , react for 20min to obtain amorphous aluminum hydroxide slurry, slowly stir and age for 48h, filter to obtain a filter cake, wash the filter cake 6 times with an appropriate amount of water by beating and washing, to obtain a filter cake, under the condition of 95 ℃, use an oven It is dried to obtain the product amorphous aluminum hydroxide. Its main properties are shown in Table 1 and figure 1 .

Embodiment 2

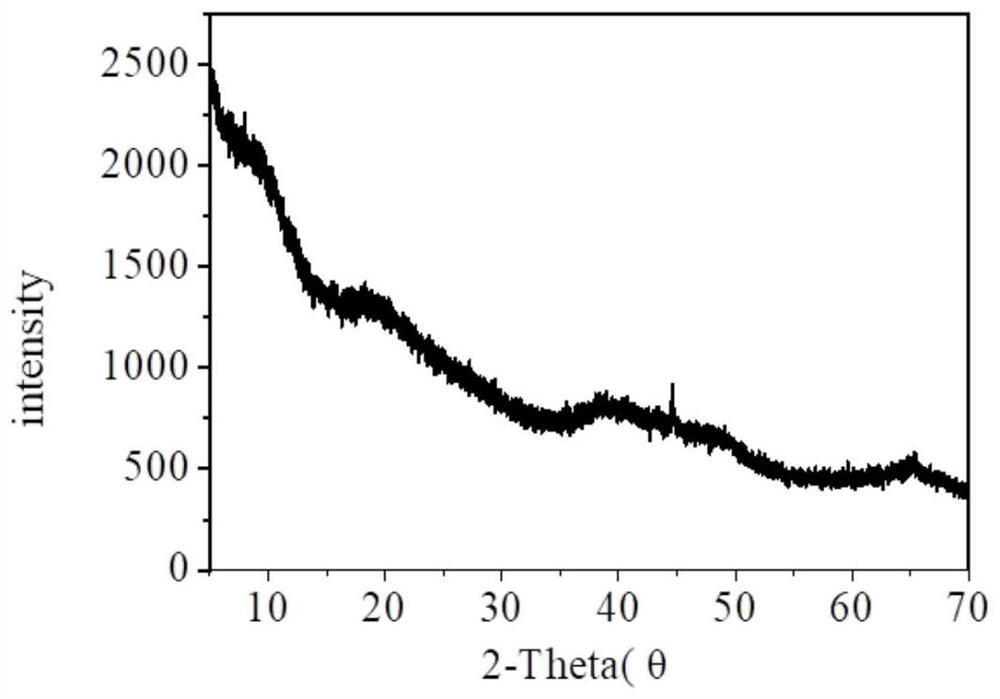

[0039] Take the sodium aluminate refined liquid, an intermediate material of the alumina sintering method, cool down to 30 °C, and pour an appropriate amount into a beaker for later use. Use aluminum chloride with an alumina content of 4.5% as the aluminum salt, and the temperature of the aluminum chloride solution is 30 ° C, start stirring, the stirring speed is 1250r / min, and the aluminum chloride is dropped into the sodium aluminate solution using a peristaltic pump, and the end point is PH. Controlled at 4.5, reacted for 20min to obtain an amorphous aluminum hydroxide slurry, slowly stirred and aged for 48h, filtered to obtain a filter cake, washed the filter cake 6 times with an appropriate amount of water by beating and washing, to obtain a filter cake, under the condition of 95 ℃ , and it is dried in an oven to obtain the product amorphous aluminum hydroxide. Its main properties are shown in Table 1 and figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com